Heidelberger Druckmaschinen AG is expanding its colour measurement and control systems and the Prinect colour workflow to meet the growing demand for efficient quality control in commercial, packaging and label printing.

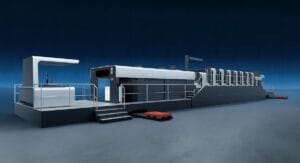

With Prinect Easy Control, Prinect Axis Control, Prinect Image Control and Prinect Inpress Control, Prinect Heidelberg the market Four spectral measuring systems for print shops of all sizes and sheetfed offset presses of all performance classes available. End-to-end spectral measurement, patented colour control and the further improved Prinect colour workflow ensure fast job changes with low waste as well as quality monitoring and logging of the print run on all Speedmaster presses. Colour control on the basis of spectral measurement values is the most promising method for achieving the desired colouring as quickly as possible in commercial, label and packaging printing.

„The consistent further development of the complete Heidelberg portfolio for spectral colour measurement enables print shops of all sizes in commercial and packaging printing to further optimise the colour workflow in the direction of the Smart Print Shop and, if required, even autonomous printing.“

Jürgen Mittmann, Senior Manager Product Management Sheetfed at Heidelberg

Since its launch in 2010, Prinect Easy Control has been installed on over 800 Speedmaster sheetfed offset presses. Now Heidelberg has the successor model to this successful measuring system was launched on the market. The centrepiece is a spectral measurement device that can be easily removed from the holder and used for other purposes (e.g. calibrations in the pre-stage). This gives the user a high degree of flexibility.

The measuring speed reaches up to 135 mm per second, a DIN A3 sheet is measured in less than four seconds. An integrated video camera supports manual adjustment to the position of the print control strip (leading edge, sheet centre, trailing edge). Prinect Easy Control can now also measure the small Dipco Micro control strips (measuring field size 3.25 x 4 millimetres). The measuring device is charged via induction in the parking position. Also The Netprofiler option for colourimetric calibration is new.

Artificial intelligence monitors in the background

Prinect Axis Control has also been revised. With a speed of 200 mm per second it is considered the fastest measuring system in its class and is equally suitable for applications in commercial and packaging printing. An autofocus automatically compensates for different substrate thicknesses during non-contact measurement. Axis Control now supports the measurement condition M1 (consideration of optical brighteners in the paper). The device automatically recognises the print control strip on the print sheet and the paper white. Thanks to tracking, Prinect Axis Control enables an exact measuring process even if the print sheet is at an angle.

When a job is started on a Speedmaster press, the colour name the optimum colour presetting and the colour run-in are set. This prevents excessive over-colouring at the start of printing. This saves paper and shortens the time it takes to continue printing. In the interests of a stable process, the Colour Assistant Pro the substrate-specific characteristic curves.

To this end, an algorithm controlled by „artificial intelligence“ monitors the colour management and the setting of the colour zones in the background and checks to what extent the settings can be improved. Thanks to of a self-learning process prevents incorrect operation by the operator due to an unfavourable learning time; the colour presettings are automatically optimised.

Source: Heidelberger Druckmaschinen AG

Heidelberg - More news

Heidelberg takes over service for Schubert in Brazil

Study shows: paper packaging is becoming significantly more important

Heidelberg acquires technology and trademark rights from Polar Mohr

Networked label printing