New plastic closures connected to the packaging require more efficient production systems. Targeted quantities of more than 100,000 units per hour can no longer be realised without high-performance servo drives, states machine manufacturer Eckel & Sohn. The company meets the high productivity and quality requirements thanks to highly dynamic single-cable servos, fast technology CPUs and standardised engineering.

From July 2024, closures for certain single-use plastic products must be designed as tethered caps throughout the EU. This means that the actual cap must remain connected to the counterpart on the bottle or pack. EU Directive 2019/904 explicitly obliges the food and beverage industry to act in this regard. This poses new challenges for manufacturers of production systems for the new closures, especially as they are rarely involved in closure design and are presented with a fait accompli at a relatively late stage, but are then faced with a new challenge. Find productive solutions quickly must.

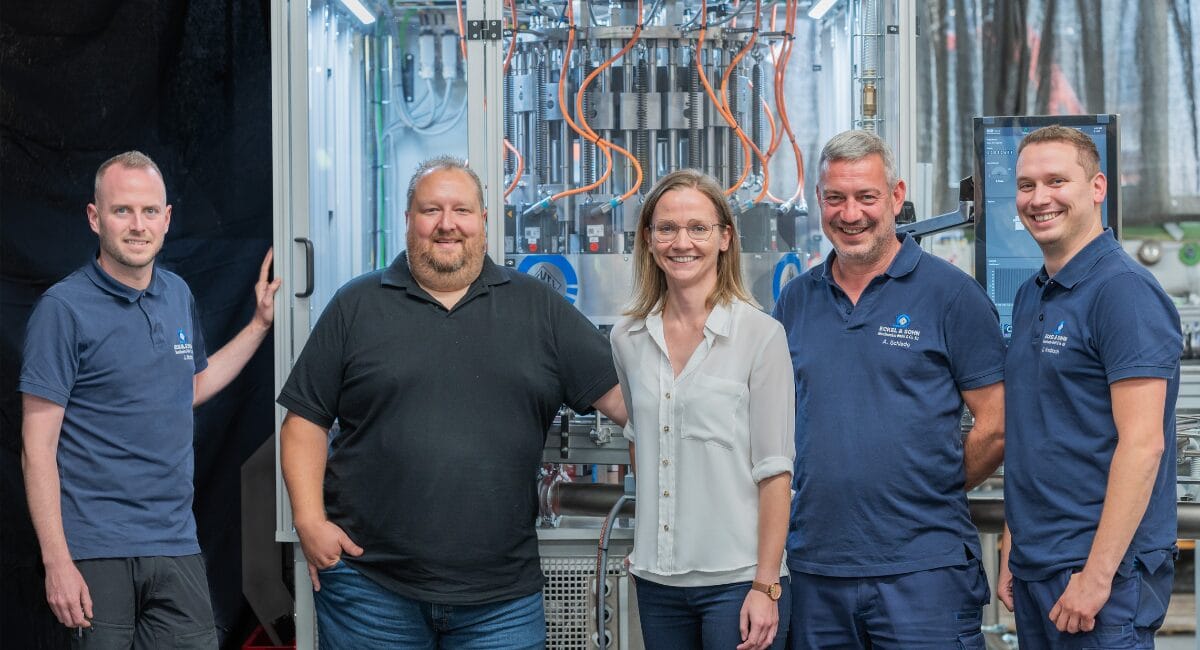

This is also known at the Eckel & Sohn Maschinenbau GmbH & Co. KG from Gau-Odernheim can sing a song. The family-run medium-sized company is one of the technology and market leaders for assembly and sorting systems for closure systems in Germany and one of the top addresses worldwide. With more than 60 years of experience, the company is highly competent and specialises in responding quickly and flexibly to the wishes of its customers. They develop and manufacture for global suppliers as well as beverage and food manufacturers Customised solutions for almost all closure typesfrom „classic“ flange part variants to sophisticated sports caps.

Simple disposable parts my arse

It is now not uncommon for four, sometimes even five individual parts to be handled and processed into a tightly resealable closure. Fully automatic, infinitely adjustable rotary assembly systems from Eckel & Sohn join, flange, rivet and cut these parts, weld them using ultrasound or induction, test them for leaks using high voltage, and assemble or screw them together. The focus is always on minimising abrasion of all fastening parts, quick format changes and Maximum flexibility with regard to product and design changes, i.e. the usability for several closure variants.

The centrepiece of each system is a central rotary tower, the number of working heads of which is adapted to the required output and design. One of the largest systems from Gau-Odernheim, with 60 heads around the clock up to 120,000 conventional flange part closures per hour.

(Image: Siemens)

Targeted quantities in excess of 100,000 units per hour push the requirements for tethered caps even higher, as new product functions generally require additional work steps and therefore often more sensors and QA systems. This leads to ever shorter reaction and cycle times for the actual assembly steps.

„This is no longer feasible without high-performance servo drives. In particular, the long-established screwing process using a torque transmitted via a magnetic coupling is simply impossible with this level of dynamics and precision.“

Jonas Martin, who is deputy plant manager at Eckel & Sohn

Integration is the key

One approach to overcoming boundaries for the machine manufacturer was and is the integration of different trades for the pre-assembly and testing of the various individual closure components. Until recently, several self-sufficient satellite systems with their own controllers and QA systems were set up for this purpose. This resulted in footprints of up to 15 x 15 metres and made it difficult to coordinate the various system components.

„Our solutions have also grown with our requirements, so that we have recently had to master and maintain several engineering tools. As the number of interfaces grew, so did the amount of coordination required, which slows down our strength and solution expertise with every optimisation.“

Alrik Schiede, Head of the electrical department

For this reason, even before the run on tethered caps, the company began to integrate as many system components as possible, including their automation and drive technology, sensors and QA systems, into the main process. This has made a significant contribution to reducing the footprint to only around six by eight metres in some cases. This frees up space in the company's own production facilities and for users, and also saves up to 80 per cent energy in.

Consistent engineering saves lead time

Marie Eckel, responsible for marketing and finance, is part of the management team.

(Image: Eckel & Sohn)

On the automation side, a high-performance engineering platform ideally integrating all subsystems and components had to be found. In a direct comparison of several candidates, the Totally Integrated Automation Portal (TIA Portal) engineering framework from Siemens convinced. The planners have developed a simplified, standardised basic process based on this, with the following options as required dockable, largely standardised processing and testing modules. This means that more than 80 per cent of systems can be generated very quickly from a kind of modular system, and only the remaining part has to be individually tailored to the respective product (range).

„Among other things, we have standardised and automated the servo drive section in the TIA portal. In future, we will simply enter the number of working heads and the system will automatically configure the required hardware. The HMI project with the corresponding screen masks for the various operating modes is also generated automatically.“

Christopher Knobloch, Deputy head of the electrical department

„After two years of experience with the universal platform and automation technology from Siemens, the Lead time in the electrical sector for planning, software development and implementation reduced by at least 50 per cent per system“ emphasises Mischa Bechtolsheimer, Head of International Sales.

Every millisecond counts

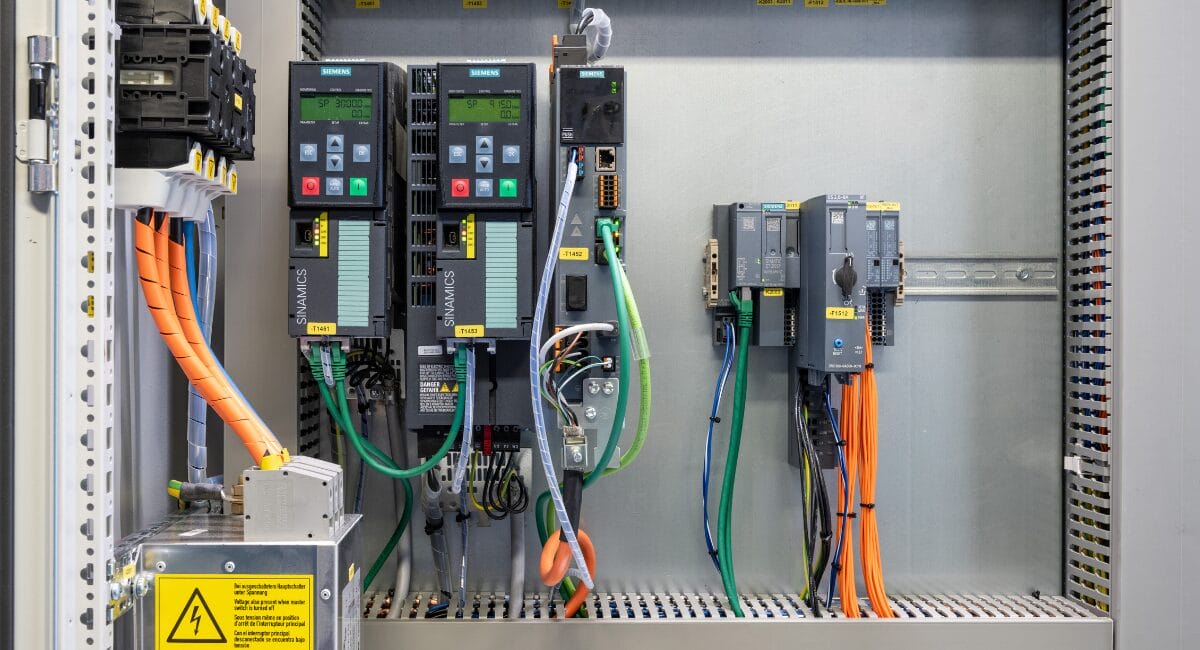

The decisive factor for consistently high process and product quality with perfect functioning of each individual closure is the Highly precise positioning and alignment of the individual parts to each other in the throughfeed. Cameras record the position of the parts and transfer them to the control system. This determines correction values and transfers the corresponding target values to the drives, which then adjust the assembly punches accordingly. Productivity is largely determined by the final alignment and joining of the caps and flange parts in the rotary tower. Controller cycle times of 1.2 to 1.4 milliseconds are essential even for quantities approaching 90,000 per hour. Handling access times of 35 to 38 milliseconds from part to part and, depending on the closure, only 20 to 150 milliseconds for positioning are also essential. The automation specialists have therefore distributed the process across two high-performance, networked Simatic S7-1500 technology CPUs. One with a fail-safe CPU S7-1517TF for the standard and safety sequences of the basic process, another with a CPU S7-1518T exclusively for the fast Profinet IRT (Isochronous Realtime) communication with the servo drives on the rotary turret. The very short, fast movements of the working heads, which are accurate to a tenth of a millimetre, can only be performed by a Highly dynamic servo drive system realise.

Those responsible opted for a new single-cable servo system from Siemens: the compact, harmonised combination of the Sinamics S210 single-axis inverter and the Simotics S-1FK2 servomotor. A customised drive concept was created in a very short time and a Siemens application engineer provided on-site support for the subsequent fine-tuning of the dynamics. This meant that all the necessary functionalities could be realised.

Easy to integrate

The Sinamics S210 frequency inverters can be quickly and easily integrated into the automation solution in the TIA Portal. The compact Sinamics S210 servo drives also fit in large numbers in the limited installation space on rotary towers with a smaller diameter. The travelling units are connected to the associated servomotors via pluggable cables, whose low moment of inertia makes them ideal for highly dynamic applications such as the assembly of caps in throughfeed. The single-cable solution combines all wires for power, encoder signal and brake control in a flexible cable less than ten millimetres thick and in a single connector.

The first plants at leading suppliers are now producing technically sophisticated tethered caps: in the Continuous operation, in the required quantities and in consistently high quality. The new approach has proven itself in practice. „Now that we have integrated automation and drive technology from Siemens, we have further powerful arguments in global competition,“ emphasises Marie Eckel, who manages the family business together with her sister, now in the fourth generation.