Kolbus is presenting its new solutions for folding and gluing packaging in a single pass at the CCE in Munich. The AutoBox machines enable the „in-house“ production of cartons, especially for companies with further processing and their own packaging trade.

Packaging can be folded and glued in a single pass with the integrated nozzle gluing system in the AutoBox AB 310. To support the manufacturing process, the machine is equipped with a Inline glue application for the folding area, so that one machine operator can operate the machine and fold and glue the boxes in a single pass. This eliminates the need to bring the box blanks into a separate gluing process.

The MultiNova MN 400 is suitable as a space-saving finishing machine for special requirements when gluing cartons and shipping crates, e.g. with automatic bottoms. Fast set-up and production speeds of up to 3,000 products per hour increase productivity in the production of boxes with multi-point gluing.

Packaging production including digital printing

AutoBox now offers single-colour inline digital printing on both the Boxer and the AutoBox AB. This allows Notes, simple logos and signets printed directly onto corrugated cardboard sheets become.

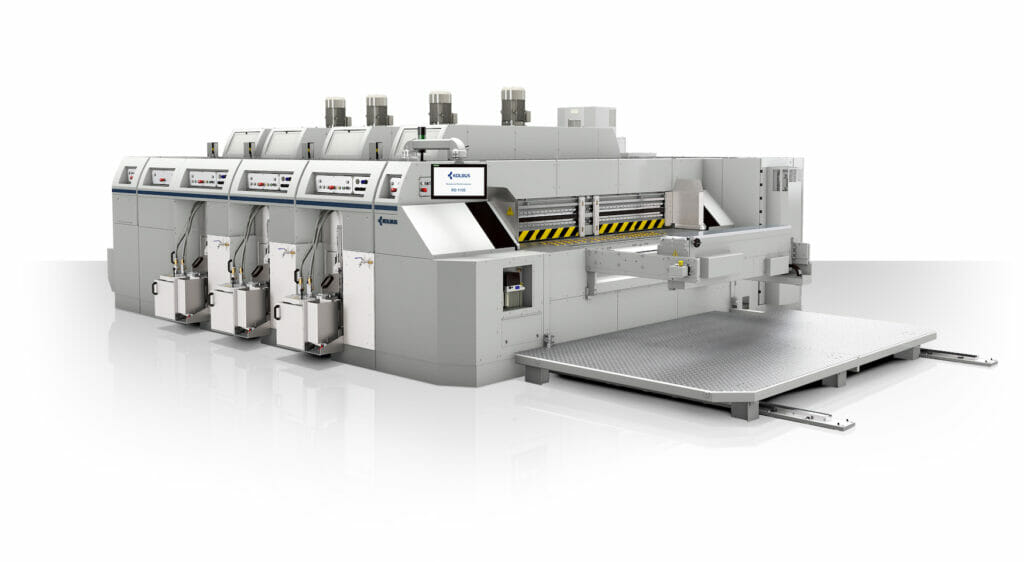

For the area of industrial corrugated board processing Kolbus has launched the new RD 115S flexographic rotary die-cutter. The solid construction and the modular machine concept for bottom and top side printing offer full flexibility for the user. The user-friendly control system with touchscreen HMIs simplifies operation and minimises set-up time and cleaning work.

Source: Kolbus

More news about digital printing

Koenig & Bauer reduces the size of the Management Board

Schumacher Packaging launches full commercial digital printing operation

Print4All 2025: The trade fair for innovation and networking in the printing industry

New head of Fujifilm's packaging division