Bobst is launching a new version of the Novafoil 106 hot stamping machine specifically for the application of holograms. The new Novafoil 106 H model offers processors flexibility in hot stamping transfer with holograms.

The Novafoil 106 was launched just two years ago. It was the first inline hot stamping press from BOBST, which had an extended transverse option, increasing its efficiency and versatility. It also offers a New quality of finishing with a newly designed embossing platen, which offers a longer dwell time, a stable platen temperature and higher pressure. guaranteed.

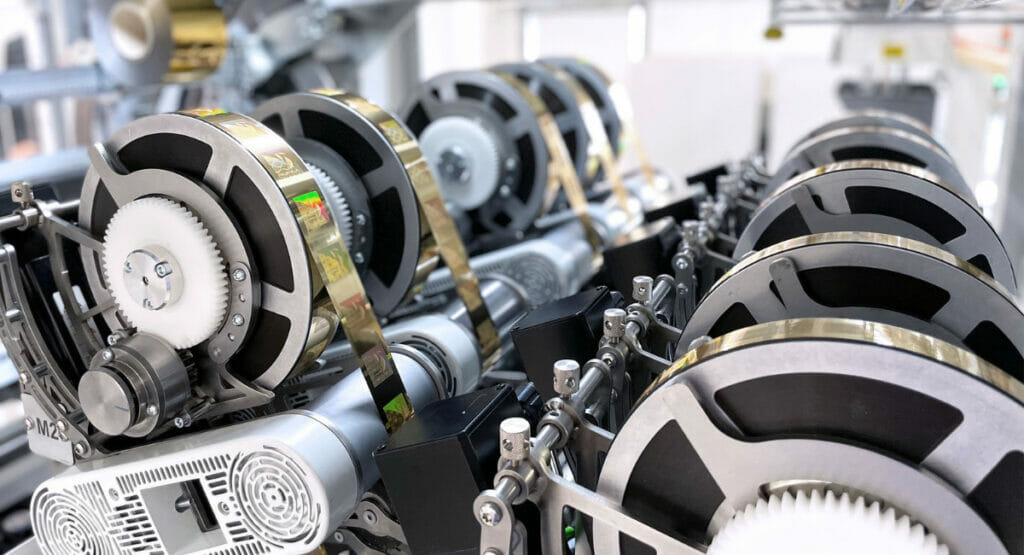

Aware of the special requirements when applying holograms, the company wanted to offer an option for processors who specialise in this area of hot transfer. The result is a new system with individual hologram modules mounted on rails in the Novafoil 106 can be used. With up to two rails and five modules each, ten hologram rolls with a maximum width of 100 mm can now process jobs in a single pass that previously required two passes.

To guarantee the flawless quality that customers expect, the Novafoil 106 H is equipped with a register for each roll to ensure accuracy during application. The film feed is controlled by an electronic system and feed shafts with pressure rollers ensure film tension. The Hologram modules can be positioned quickly and hologram rolls can be inserted within seconds. can be connected. In addition, the modules can be plugged directly into one of the two connection boxes on either side of the machine. This „plug-and-play“ system ensures Quick and easy conversions.

To reduce set-up times even further, BOBST has introduced the Digital Makeready Tool (DMT). Based on the Digital Inspection Table (DIT) quality control solution, the PDF file of each finishing job can be sent to the DMT, thereby minimising set-up times. Digital layout projected directly onto the clamping frame with honeycomb plate is created. This projection shows exactly where the embossing tools need to be positioned, eliminating the need for time-consuming set-up checks. The DMT shortens set-up times and increases precision, to ensure embossing register quality, which in turn reduces the number of faulty print sheets.

Source: Bobst

Further news on packaging finishing

Sparxell scales plant-based textured colours

SVI publishes guideline

Butterfly takes over ePac Flexible Packaging

GIO-compliant printing inks for food packaging