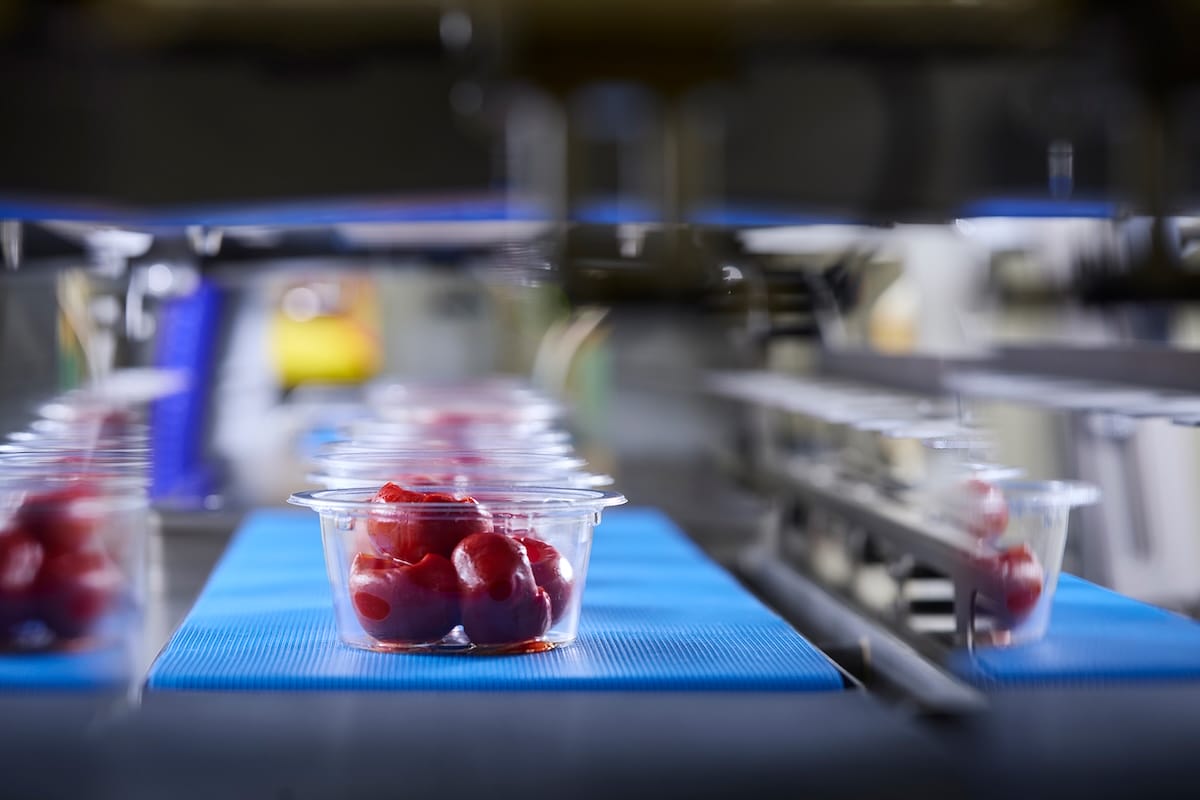

With the QX-800, Ishida Europe is launching a new generation of traysealers designed for efficiency, flexibility and sustainability. The machine not only offers high packaging performance, but also significant energy savings - with a compact design and simple operation.

Ishida Europe is expanding its tray sealing portfolio with the QX-800 - a new machine tailored to high-performance production lines. In addition to pure speed, the development focussed on energy efficiency, ease of operation and a wide range of formats. The QX-800 was designed for manufacturers who rely on modern, scalable and automatable packaging solutions.

With an output of up to 25 cycles per minute in standard sealing mode and up to 17 cycles in modified atmosphere mode (MAP), the machine achieves a throughput of up to 175 trays per minute when using a seven-cavity mould. .

Energy saving of 50 % compared to the previous series

Compared to the QX-Flex series, Ishida has been able to reduce energy consumption by around 50 per cent. The machine does not require compressed air or water cooling, which not only protects the environment, but also reduces operating and maintenance costs. .

A newly developed, patented transfer system ensures particularly gentle product handling - even with delicate or difficult-to-handle foods such as soups. This prevents spillages and reduces food loss.

Compact, intelligent, user-friendly

The QX-800 was developed with existing production environments in mind. It can be integrated to save space and is therefore also suitable for retrofit solutions. Folding doors and a minimised tool tray reduce the footprint. The tools themselves weigh less than 70 kilograms and can be changed in just five minutes, according to the manufacturer. .

The user interface has also been completely redesigned. It provides real-time information on performance data and offers quick access to operating instructions and technical information. Presettings for mould configurations can be saved and transferred - further reducing downtimes.

High compatibility of materials and formats

The machine is suitable for a wide range of tray shapes and materials - including plastic, cardboard, aluminium and fibre-based materials. „In the highly competitive food market, this feature profile is crucial,“ says Tara O'Connor, Product Manager at Ishida Europe. „Because it enables more efficient production without compromising food safety or the appearance of the packaging“. .

At the same time, the machine helps to reduce the carbon footprint as it is energy-efficient and can be combined particularly well with sustainable packaging designs. Ishida therefore sees the QX-800 not only as a technical advance, but also as a contribution to the switch to more resource-efficient packaging concepts.

All photos: © ISHIDA