This year's LogiMAT ended after three days of the fair with another highn Audience response. Almost 66,000 trade visitors came to Stuttgart to find out about innovations in intralogistics in the ten fully booked exhibition halls. We also took a look around the trade fair.

The ten exhibition halls were already bustling with activity early on the first day of the trade fair. 1,625 exhibitors from 40 countries, including more than 300 first-time exhibitors, presented their latest product developments for efficiency and sustainability in intralogistics. Around 140 new products celebrated their world and European premiere in Stuttgart. The supporting programme was also very well attended.

„In addition to the pure performance show, elementary soft skills in the LogiMAT concept characterise the success of the trade fair. Among other things, the exchange of information in a supporting programme at congress level, exciting live events and the Mobile Robotics User Forum characterise the added value of LogiMAT.“

Michael Ruchty, Exhibition Director LogiMAT

The human side of automation

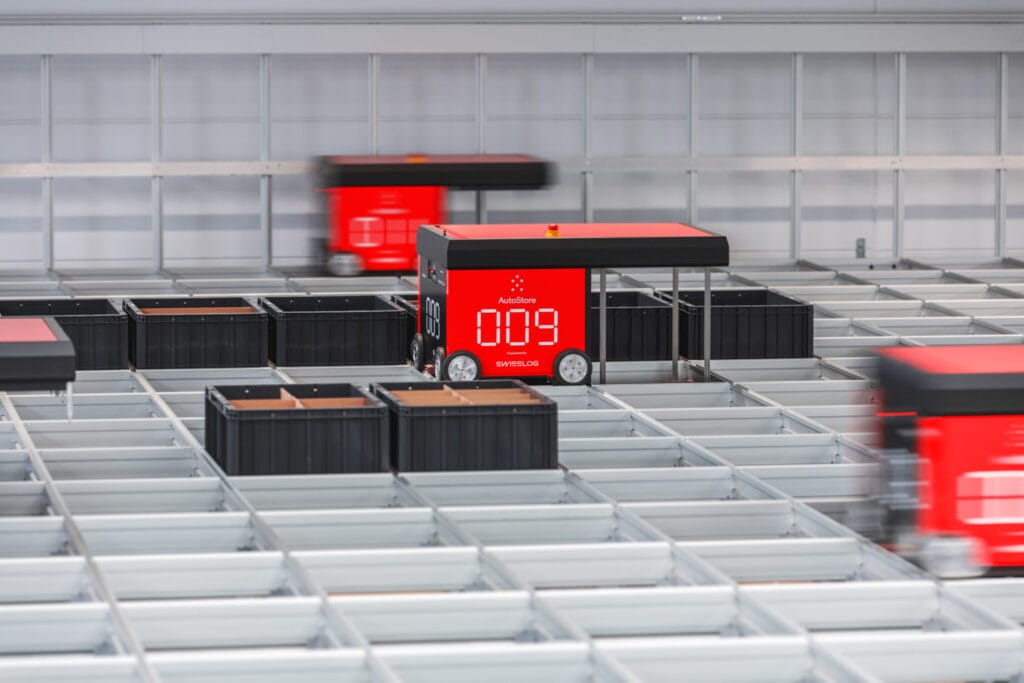

Swisslog, the logistics expert of the Kuka Group, had chosen „The Human Side of Automation“ as the motto for its trade fair appearance, emphasising its commitment to the human side of automation. „We want to support people at every stage of the supply chain with our solutions,“ said Markus Kirchhoff, Senior VP Sales & Accounts EMEA at Swisslog. The company showcased its data-driven and robotic solutions for logistics automation, including a new multi-temperature solution. This takes into account several temperature zones within a single system so that products with different temperature requirements (-25°C to 6°C) can be stored. What is new is the ability to, Seamlessly integrate a deep-freeze storage zone into a refrigeration network, This means that separate deep-freeze zones and cooling zones within a warehouse are no longer necessary. The Swiss company is also celebrating in its 125th anniversary this year.

Dutch company Sparck Technologies also presented an innovation. The specialist for automated packaging solutions showcased a pick-to-box solution that enables Picking directly into the shipping packaging enables. The CVP system first produces an open packaging unit for which the correct size has been automatically calculated beforehand. This is then filled in the picking area and transported back to the system, where it is automatically fitted with a precisely fitting lid. With this innovation, Sparck combines two packaging strategies, as the Sparck systems also produce Precisely fitting packaging directly around stacked goods in a consignment. A 3D scanner records each stack and determines the minimum size of the carton. „Our system knows exactly how big the packaging needs to be,“ says Claus Weigel, International Senior Sales Manager at Sparck. „Another new feature is that the three corrugated cardboard feeders not only offer three different widths, they can now also have different thicknesses or flute types, thereby further optimising the weight.“

At the trade fair, Strautmann presented its new waste management system BaleConnect which will connect all Strautmann balers via a user-friendly platform. With real-time data, automated notifications and data-based analyses, customers will always be up to date. The new system is designed for Use with individual machines or an entire fleet. „The system is currently available for our AutoLoadBaler. In the future, however, all other Strautmann balers will be networked via BaleConnect,“ says Marketing Manager Sophia Brandmann. With BaleConnect, faults can be detected at an early stage and hidden potential can be uncovered and processes optimised with the help of data-based analyses.

Pallet change with automatic stacking function

SW-Paratus from Halle (Westphalia) also presented a new development: The Paratus Change +Stack can change and stack pallets in the tightest of spaces. It was developed as a modification of the existing Paratus Change +Lift system and combines pallet changing in seconds with an automatic stacking function, but requires significantly less storage and manoeuvring space than the +LIFT. „During development, we responded to a key need of our customers, because every square metre counts in logistics,“ explains SW-Paratus founder Lars Wellerdiek. The new pallet changer automatically stacks up to 15 pallets directly above the push-out area of the changer - a time and space-saving solution for warehouse operations that is also more cost-effective.

At the stand of the Irish company Combilift, forklift truck solutions of various sizes were on display. The focus was primarily on space-saving design and electromobility. The company spends 98 per cent of its R&D investment volume on the Development of energy-saving and electric drives, which now account for over 70 per cent of total production. One of the trade fair highlights was the Aisle Master VNA series. The forklifts can be used in aisles just 1.60 metres wide. This allows the Increase storage capacity in existing rooms by up to 50 per cent. This allows companies to optimise their space utilisation and avoid expansions or relocations. The universal one-truck solution is also able to move loads directly from the yard into covered storage areas and increase productivity with this „truck-to-rack“ function.

The next LogiMAT in Stuttgart will take place from 24 to 26 March 2026.