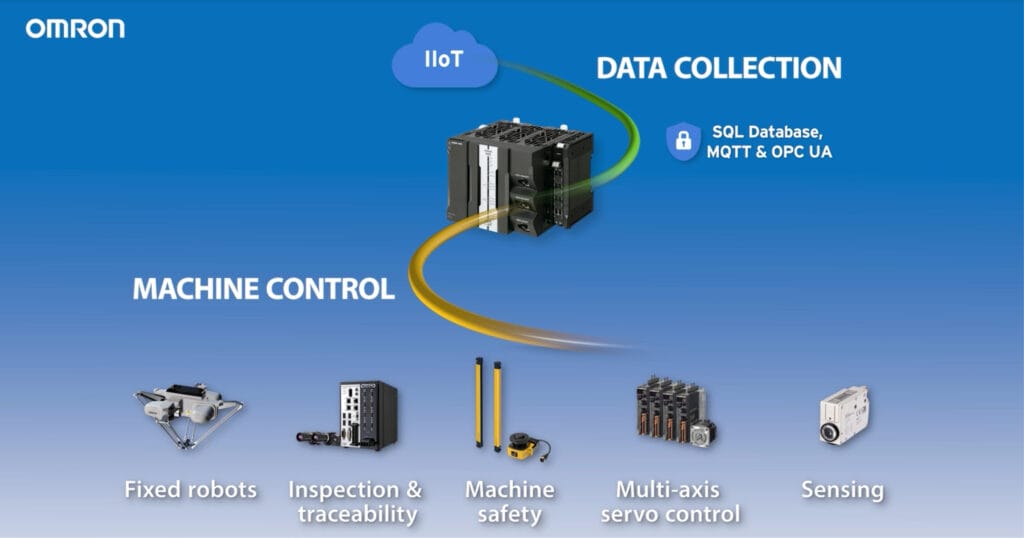

With its new Robotics Packaging Library, Omron presents a powerful solution for the automation of complex packaging processes. The library enables seamless integration of robotics and PLC control and manages all aspects of the packaging line on a single software platform.

Integrating robots into a packaging line can feel like a complicated 5,000-piece puzzle. Developing a high-performance packaging line with multiple robots is often about Complex integrations, precise motion control and compliance with tight production specifications. Whether you are a system integrator developing customised solutions for specific customer requirements or an OEM developing scalable, standardised systems: The Omron Robotics Packaging Library provides the tools companies need to simplify integration and save time during development.

Today more than ever, packaging lines need to work quickly, precisely and flexibly. This is precisely where the Robotics Packaging Library comes in. The platform supports the simultaneous use of multiple robots - The NX5/NX7 supports up to 16 robots, the NJ5R up to 5 robots - and allows real-time coordination with motion and vision systems.

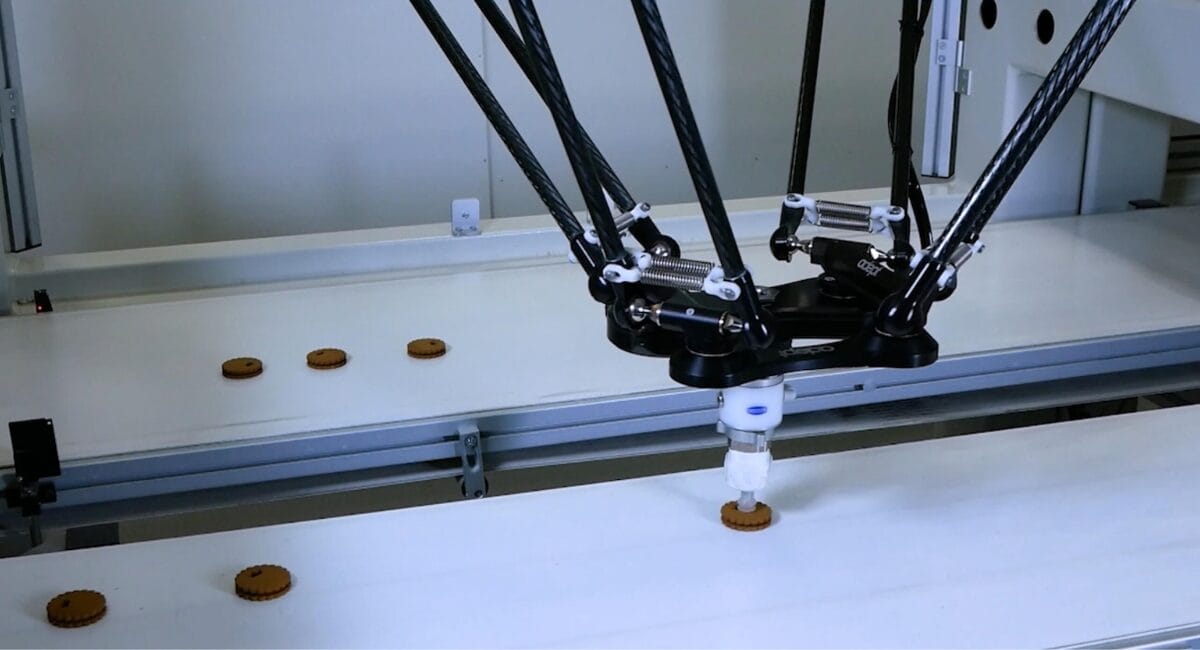

The library is compatible with a wide range of kinematics - including customised configurations with up to four degrees of freedom. This enables the Realisation of complex movement sequences, for pick-and-place applications or the handling of sensitive products with special grippers.

Motion control at the highest level

Another highlight of the library is the optimised motion control. Thanks to innovative functions such as blending for smooth transitions, dynamic blending for real-time reaction to changes and customisable motion profiles, it is possible to Adapt robot movements precisely to the requirements of the line. This shortens cycle times and at the same time guarantees high process stability.

Intelligent conveyor belt tracking

The synchronisation of robots with conveyor technology is crucial for efficient packaging automation. The Robotics Packaging Library offers Advanced tracking functions for linear and circular conveyor belts. Multiple actions can be performed on a conveyor belt without interruption - including real-time change of tool coordinates and movement frames. Functions such as PathOffset enable the handling of overlapping product paths, while adaptive speed compensation ensures maximum repeat accuracy.

Three advantages for the practice

Reduced cycle times through seamless motion transitions and powerful tracking.

Simplified system architecture with a centralised control and software solution.

Maximum flexibility thanks to support for Omron and third-party robotics as well as customised kinematics.

Future-proof and efficient

The Omron Robotics Packaging Library is a practical solution for the development of high-performance robot systems in the packaging industry. It combines robotics and PLC control, includes advanced motion functions and supports both standard and customised hardware configurations. With the library, companies can develop powerful yet flexible packaging lines that help them remain competitive.

Source: Omron