In particular, cost drivers that are often not given sufficient consideration by customers at the start of the procurement of a new labelling system become apparent. The costs of downtime are most often overlooked when it comes to coding and labelling. Downtime can be caused by both poor print quality and inadequate printer performance. are caused. Some conventional printers need to be cleaned between production breaks. This means that the production line is at a standstill while someone carries out the cleaning cycle for the printer. Some printers need up to 20 minutes to stabilise before they are ready to print again.

This delay costs money: According to the „True Cost of Downtime Report by Senseye“, the cost of one hour of production downtime varies between 39,000 US dollars in the FMCG industry and more than 2 million US dollars in the automotive industry. Leibinger prevents this cost driver with its unique printer technology and keeps unused ink in a 100 per cent airtight system. It does not dry out and does not clog the print head. This means that production schedules do not have to be based on cleaning cycles and neither valuable production time nor money is wasted. High-quality print results are guaranteed at all times.

Maintenance as a cost driver

It is important that machines are maintained and in good condition and this can account for a significant proportion of the overall costs. With its IQJET CIJ printer, Leibinger is able to reduce costs here. Because the IQJET is Maintenance-free for five years. This is possible thanks to the use of durable, high-quality components and a unique product design that minimises wear and tear (e.g. customers do not need a constantly running feed pump). In addition, maintenance costs are completely eliminated.

The maintenance and spare parts policy should be one of the most important aspects that food manufacturers should clarify with their supplier of labelling and printing solutions, as it can represent a considerable cost factor in the long term.

With the current labour shortage, it is particularly important to consider the cost of labour. Printers with Easy installation, management and configuration, The use of remote control options, for example, costs less in the long term because employees do not have to travel kilometres around the factory to operate them. Such functions are a matter of course with Leibinger printers. The plug & print features of the IQJET are unrivalled on the world market. The drag-and-drop user interface allows print jobs to be created effortlessly and intuitively; there is no need for time-consuming employee training.

Material and electricity

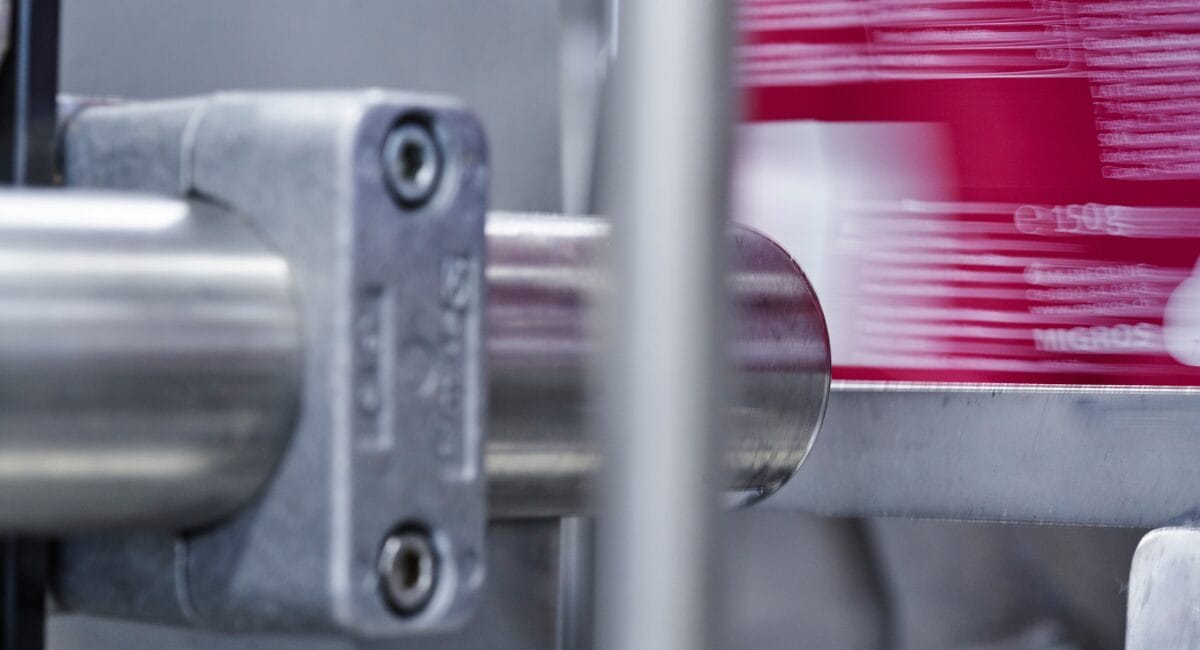

Printers that use less ink and solvent reduce packaging line costs - but not all printers are created equal. Leibinger's latest printers have one of the lowest consumptions on the market - 2.7ml of solvent per hour for MEK inks (competitor products typically consume between 6 and 10ml per hour). In addition, the German labelling expert ensures that the Ink cartridges emptied to the last drop and do not have to be disposed of separately (unlike many conventional CIJ systems).

Energy prices are still high, so the electricity required to run a printer is an important factor. Electricity not only costs money, but also contributes to a company's ecological footprint. If manufacturers decide in favour of Appliances with low power consumption, With a power consumption of only 36 W, as with the new Leibinger IQJET, it is cheaper to operate than any other printer.

Source: Leibinger