At the Hannover Messe, igus is showcasing smart sensor technology for AI-supported low-cost robotics and its AI-based app for optimising applications with lubrication-free motion plastics.

Artificial intelligence (AI) simplifies the work of design engineers right from the selection of suitable components. This proves igus at the Hannover Messe with igusGO. The AI-based app reveals in a matter of seconds how an application can be technically optimised with lubrication-free components from the company. The App recognises the object with AI algorithms and makes suggestions for igus products that increase reliability and reduce costs.

A new joint study by scientists at RWTH Aachen University and igus has now quantified the economic and ecological benefits of lubrication-free polymer bearings for the first time: Depending on the application, between 7,000 and 14 million euros can be saved per year. Save purchasing costs for lubricants. At the same time, the switch to polymer bearings offers CO2-savings potential.

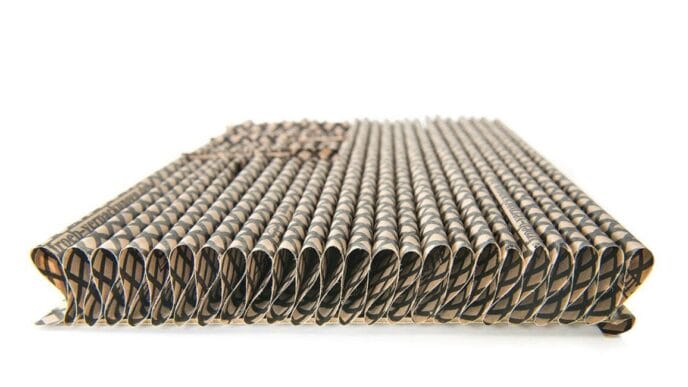

Plastics from igus are also intelligent. On show at Hannover Messe 2024 are the igus smart plastics, i.e. energy chain systems, cables, linear guides and plain, articulated and rotary table bearings, which Equipped with intelligent sensors are. They not only enable real-time condition monitoring, but can also be connected to various networks and IoT systems and thus integrated into a predictive maintenance concept in order to avoid expensive production downtimes caused by unplanned plant shutdowns. With the help of sensors, evaluation modules and software, a Dynamic service life calculation realised and optimum maintenance times for the products - which also offers an advantage in terms of sustainability. This is because products are not replaced unnecessarily early, but only when they have reached the end of their product life cycle.

AI for optimisation and maintenance

With the „superwise“ digital service, it is possible to keep an eye on your own applications at all times via a centralised dashboard with little personnel effort. This turns the Intelligent linking of application, product and sensor data as well as the optional use of the Internet of Things to provide comprehensive „plastics intelligence“. The customer automatically receives Timely maintenance recommendations, offers, warnings or suggestions for improvement. If companies do not have time to keep an eye on their applications themselves, igus takes on this responsibility. Employees then report proactively when something needs to be done.

„The superwise service combines the modern sensor technology of smart plastics with an all-round digital service. In times of multiple crises, it is digital innovations like these that are more decisive than ever for the competitiveness of companies. It is important to us that small and medium-sized companies without in-depth expertise and with low budgets can also benefit from trends such as predictive maintenance.“

Michael Blass, Managing Director e-chain systems at igus

All robots at igus are „made in Cologne“ - from injection moulding and PCB assembly to programming. This also includes the ReBeL Cobot. For users looking for an even more compact solution, igus has developed the ReBeL KID. Visitors to the preview will already be able to see an Education AGV, a Open source solution and autonomous learning platform consisting of an automated guided vehicle system (AGV), which can be combined with cobots such as the ReBeL or the ReBeL KID. Customers can combine compatible low-cost accessories from over 100 manufacturers, such as grippers or vision systems, via the RBTX online marketplace using the plug-and-play principle - supported by online tools and 3D models. RBTX is designed to help companies of all sizes get started with automation at low cost.

In addition, igus offers products with AI-based voice and gesture control on. Amazon Alexa can be connected directly to the igus robots or gesture control can be integrated via ROS 2. This will make it easy to define robot movements in the future. Such AI-supported, intuitive operability combined with a low price paves the way for low-cost robotics to enter the mass market. igus is currently using AI primarily to Monitor robots and integrate vision sensors quickly and easily. However, the robotics team is also researching resilient programming using speech or gestures. Simple robot programming for everyone that is not just limited to the robot, but realises the entire application.

Source: igus