With a new adhesive application system from Baumer hhs, outer packaging as well as transport and shipping cartons on pallets can be secured with anti-slip adhesive. The company is thus supporting the industry's efforts to minimise packaging waste - and its endeavours to eliminate plastics from packaging processes wherever possible and to work in a more resource-efficient manner.

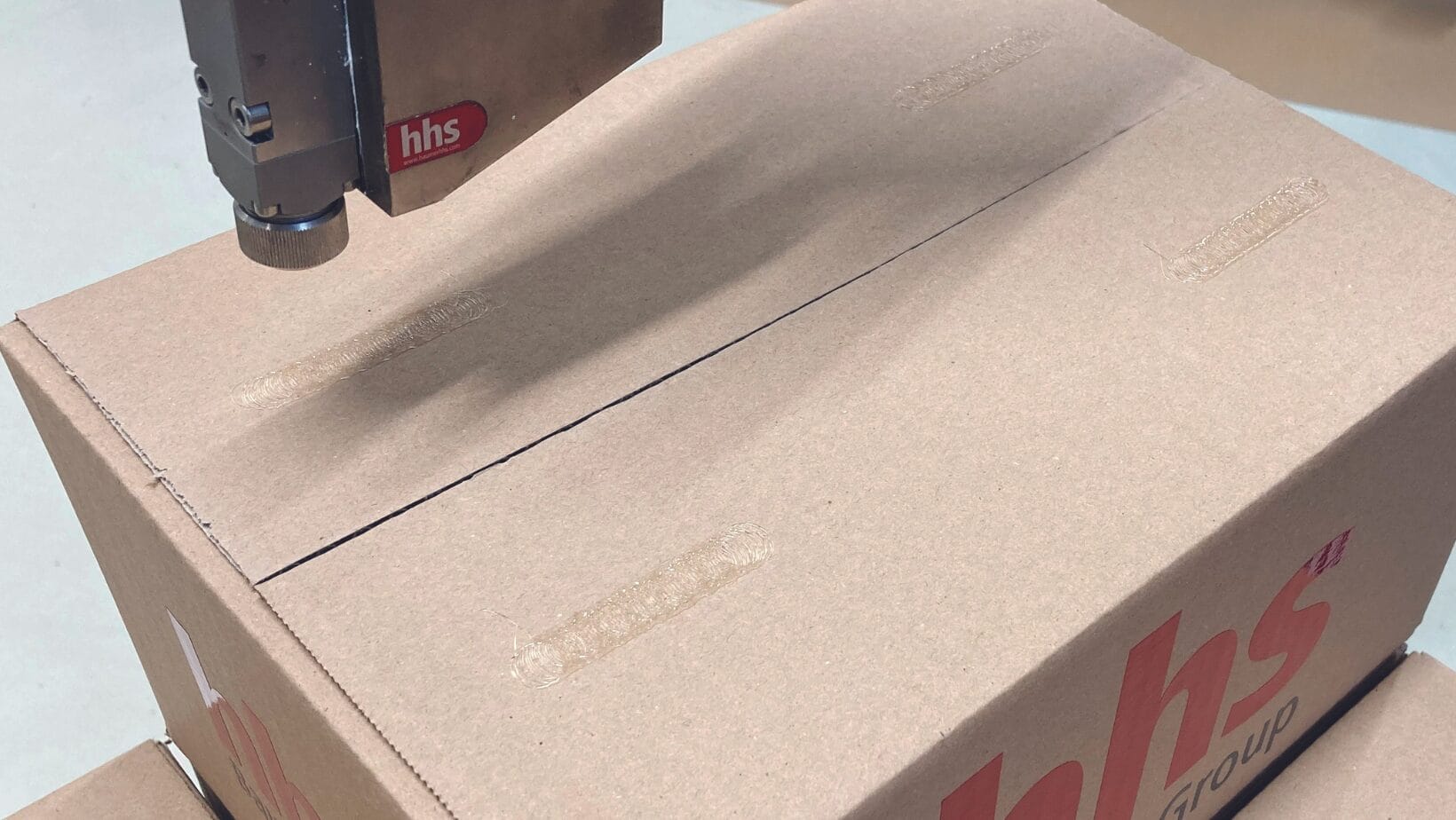

The principle is as simple as it is intelligent: with the new adhesive application system Anti-slip adhesive sprayed onto the cartons before palletising. Even small quantities of these hot-melt adhesives are sufficient to fix packaging - ideally stacked interlocked - on all layers of pallets and ensure that it does not slip during transport. Internal transport in particular can even be carried out completely without film.

As a result, the use of plastic films - for example stretch and wrapping films or shrink sleeves - in pallet securing is reduced to a minimum with the new solution. This resource-saving innovation from Baumer hhs therefore reduces the volume of waste to be disposed of, which cost savings and simplifies logistics processes.

This reduces the amount of work involved in depalletising, as less plastic film needs to be removed. Intermediate pallet layers such as anti-slip paper can be omitted completely. In times of acute labour shortages, this simplification in logistics can be an important aspect for industrial companies. In addition, depalletising reduces the risk of accidents. This exists when packaging filled with goods can slide off pallets, workers cut the plastic film with sharp knives or the film waste lies around on the floor as a tripping hazard.

Added to this are the Improved environmental footprint of transport and logistics processes, which result from the considerable reduction in plastic consumption and the drastic reduction in film waste. Another ecological aspect: the packaging sprayed with the small amounts of anti-slip adhesive can be easily recycled. recycled via the existing recycling loop for paper become.

„With this resource-saving innovation for pallet and transport securing, we are virtually knocking down open doors in the market. After demonstrating its significant advantages in practice during initial installations at renowned industrial companies in various sectors, we are now supplying it worldwide.“

Martin Kotecki, Business Development Manager Packaging at Baumer hhs

Some companies have already had several packaging lines equipped with the new adhesive application system in parallel. Thanks to the significant reduction in film consumption alone Investments amortise within about a year.

As a complete solution, the new system can be flexibly integrated into conveyor belts according to the plug & play principle. between the final filling and palletising of outer packaging, transport or shipping cartons can be integrated. The basic package includes a holder with crossbeam, two HM-500 hot melt spray valves, a sensor for recognising the packaging, an Xmelt melter and an Xact control unit. The system is flexibly scalable depending on customer requirements. The HM-500 valves also guarantee versatility: they reliably apply all standard pressure-sensitive adhesives with different levels of adhesion or stickiness.

Source: Baumer hhs