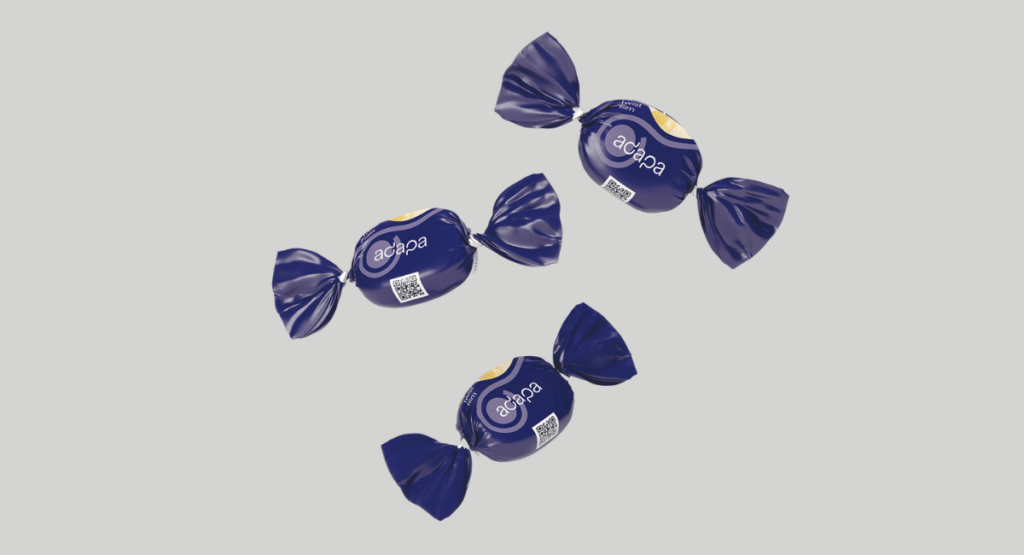

adapa presents a new packaging for confectionery such as toffees, caramels and sweets. The paper-based twist-wrap PaperTwister(re) also runs on high-speed machines and is certified as „repulpable“.

The PaperTwister(re) is available in thicknesses from 40 to 50 g/m2 and can be used as a Single or double twist and for folding applications can be used. It has been developed to run on the fastest twist packaging machines on the market and works on established lines as well as on the latest high-speed packaging machines. With a proven output of 2,300 pieces/min, the Twist-Wrap, which is available in standard paper and metallised versions, delivers reliable performance.

adapa shows how this performance can be combined with sustainability: The new fibre-based PaperTwister(re) with a Papier content of 90 per cent and a plant-based coating has been certified by independent institutes as „repulpable“ in accordance with the new CEPI (4EverGreen) and OPRL (CPI) standards. According to these standards, any new fibre-based packaging should be designed with the circular economy in mind.

The PaperTwister(re) not only fulfils the requirements of manufacturers and consumers for paper packaging, but also combines this with convenience: a reliable and Easy-to-open deadfold is combined with a very good release function in this product, which prevents sticky confectionery products in particular from sticking to the packaging. For an eye-catching appearance, the innovative PaperTwister(re) can be packaged in a Palette printed in up to eight colours become.

The development is backed by the Group's 100 years of experience in twist packaging and paper processing. Over the years adapa has developed a diverse range of twist packaging solutions in both paper and plastic, including strip lamination for both. Within the paper twist packaging, customers can choose between various versions that are conventionally waxed with paraffin, paraffin-free, palm oil-free, wax-free or designed for recycling are. In addition, a specialised version of the paper twist wrap is available, which is designed for increased mechanical resilience.

With up to 98 per cent paper content and good machine running performance, adapa's range of paper solutions meets most customer expectations in modern confectionery packaging. Manufacturers of premium brands also benefit from the many years of experience with stripe lamination. This sophisticated technology can be applied to both plastic and paper and gives the product a particularly high-quality look and feel.

„The PaperTwister(re) combines performance and sustainability and fits perfectly into our comprehensive range of paper and plastic-based twist wraps for confectionery. We are proud to announce that our latest development has won over industry professionals: With the PaperTwister(re) we are shortlisted in the ‚Innovation of the Year‘ category at the UK Packaging Awards 2023.“

Richard Bell, Head of Research and Development for Confectionery, Tea & Coffee and Home & Personal Care at adapa

Source: adapa

Mondi - More news

Mondi develops recyclable paper packaging for bicycles

Top Ten 2025: German Packaging Award 2025 - These are the winners

Mondi officially inaugurates new paper machine at Štětí mill

Modernising coffee packaging for the future