Faller Packaging, Perlen Packaging, Uhlmann Pac-Systeme and Etimex Primary Packaging have set themselves the goal of making packaging in the pharmaceutical industry more sustainable. For example, they are now introducing polypropylene (PP) pharmaceutical blister packs as an environmentally friendly alternative to traditional material combinations such as PVC with aluminium.

Establishing a sustainable solution that also fulfils the strict requirements of the pharmaceutical industry also requires a new type of collaboration along the entire value chain, according to the companies. Because Sustainability is also increasingly becoming a must in the pharmaceutical industry. Customers and regulatory authorities demand packaging that is environmentally friendly and recyclable without jeopardising the high standards of stability, barrier properties and processability. At the same time, conventional material combinations such as PVC with aluminium are reaching their limits when it comes to recyclability. The four established companies decided to tackle the challenge together - and PP blister as the solution of the future to establish.

Collaboration as a driver of innovation

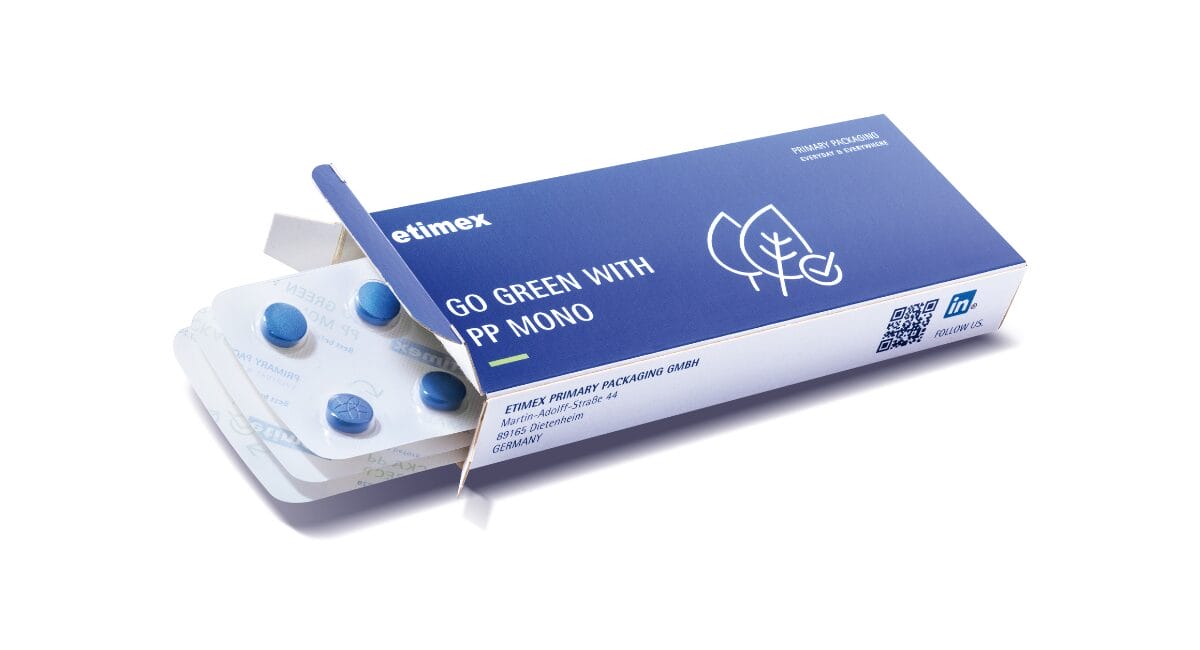

The journey began at Etimex, a manufacturer of PP blister films. Its materials had already proven that they are recyclable and at the same time meet the demanding requirements of the pharmaceutical industry. can be realised. Perlen Packaging joined the partnership as a driving force and contributed its expertise in the Analysing material properties and marketing for various areas of application. Together with Etimex, extensive material tests were carried out on a modern blister machine from Uhlmann. This machine allowed the team to Test and optimise PP solutions under realistic conditions and confirm their suitability for practical use. Faller Packaging closed the circle with sustainable cardboard outer packaging that was perfectly matched to the PP blister packs. The result was a Integrated solution across the entire value chain away.

The results of the collaboration speak for themselves. Initial tests on the Uhlmann blister machine have shown that the PP films from Etimex not only fulfil the strict requirements of the pharmaceutical industry, but are also the best choice when it comes to packaging. Stability, barrier properties and processability convince.

Source: Etimex