The Dutch company Avantium has developed a technology that converts plant sugars into a fully recyclable polymer, known as PEF. The nova-Institute has now carried out a life cycle analysis of Avantium's PEF applications. The result: the new bio-based polymer has a low CO2-footprint.

When using renewable carbon in PEF (polyethylene furanoate) instead of fossil carbon in PET in the production of 250 and 500 ml bottles According to the study, this will lead to a considerable reduction in greenhouse gas emissions. Plant-based carbon has a net-neutral impact on CO2-concentration in the atmosphere. In contrast, materials and polymers based on fossil carbon (e.g. crude oil) release additional CO2 into the atmosphere.

The main building block of the new, bio-based polymer is FDCA (2,5-furandicarboxylic acid), which is obtained from sugars such as wheat, maize and sugar beet. When the technology is fully developed, PEF will also be produced from cellulose and thus from agricultural and forestry waste streams. Avantium's current process is based on starch from European wheat. The world's first commercial FDCA plant is scheduled to go into operation in 2024.

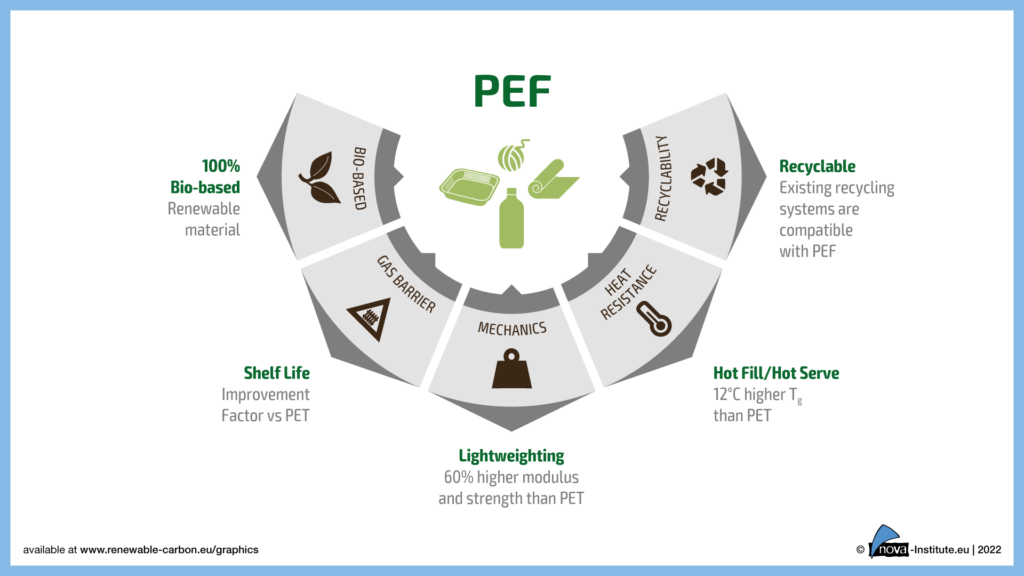

According to the nova-Institute, PEF has the following advantages over PET has improved barrier properties, is mechanically and chemically recyclable and can also be recycled as part of the established PET recycling process. PEF is 12 °C more heat-resistant than PET and has a higher strength. This enables the development of lightweight packaging made from PEF with lower resource consumption. Avantium has already used the innovative, plant-based packaging material on a pilot scale and recently started construction of an FDCA plant with a capacity of 5,000 tonnes per year in Delfzijl in the Netherlands.

PEF also for multi-layer applications

The nova-Institute has carried out a complete cradle-to-grave life cycle analysis (LCA), which is part of the European PEFerence project. It assesses 16 different impact categories covering all relevant life cycle phases. The comparative analysis shows that PEF bottles can reduce greenhouse gas emissions by around a third compared to PET reference bottles. The biopolymer also reduces the consumption of finite resources by 45 per cent. In addition to pure PEF bottles, the polymer can also be used to produce multilayer packaging. Here PEF offers a Good passive barrier for O2 and CO2 and could potentially help to reduce the environmental footprint of packaging solutions by extending the shelf life of products, enabling lower packaging weight and improving recyclability.

In the LCA, 250 ml multi-layer PET bottles with a PEF content of ten per cent were also examined and compared with PET/PA reference bottles. These had a normal PA (polyamide) content of seven per cent. The result: replacing the PA layer with PEF reduces greenhouse gas emissions by around 37 per cent, which is mainly due to on the recyclability of the PET/PEF system compared to the non-recyclability of the PA-containing system is due.

Green Packaging - More news

Adapa presents sustainable solutions for PPWR implementation

Researchers develop compostable food packaging

Dry forming goes industrial: Yangi starts fibre tray production

One.five supplies high-barrier paper for vegan cheese