Polyvel Europe is introducing a new masterbatch, a PFAS-free process aid for the extrusion of packaging films, to support the food industry in complying with the EU regulation, which provides for comprehensive bans on PFAS in plastic packaging from October 2026.

The innovation supports the food industry in particular in complying with the strict EU regulation of 20 September 2024. gradually bans the use of poly- and perfluorinated alkyl substances (PFAS) in food packaging. Masterbatch S-2899 sustainably reduces melt fractures, improves the production process in particular by preventing material build-up at the nozzle and also allows higher processing speeds.

The new masterbatch fulfils both the current EU directives as well as the requirements of the US FDA for food contact.

FSuitable for food packaging films

The innovation is based on a Completely PFAS- and siloxane-free technology, in which the processing aid S-2899 is distributed very finely and evenly. This ensures consistent and fluctuation-free dosing. It is versatile in use and is suitable for all polyolefins such as LLDPE, LDPE, HDPE and PP as well as for corresponding recycled pellets. With a dosage of just 1.0 to 2.0 per cent, it offers a cost-effective solution for the production of high-quality food packaging films.

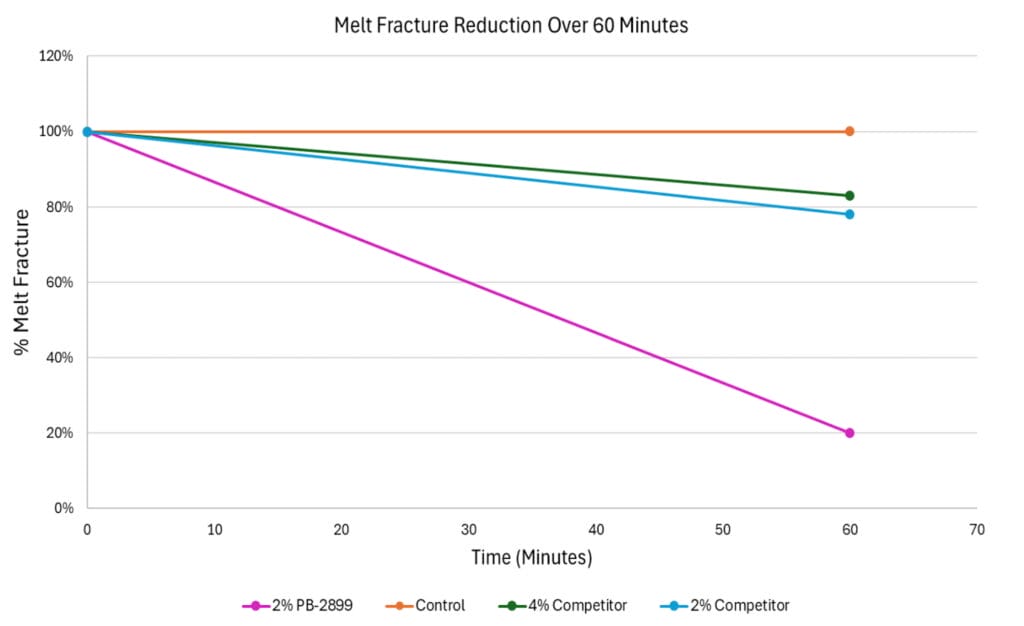

As the extrusion of polyolefin profiles, films and sheets places high demands on the quality of the surfaces, the new masterbatch has been designed to prevent defects such as melt fractures and minimises the so-called „shark skin“ phenomenon. This effect occurs during the extrusion process due to stress fractures and pressure fluctuations on the surface of the extruded plastic as it leaves the die. It leads to a rough, sharkskin-like structure, limits the extrusion speed and impairs the surface quality.

Fewer melt fractures and higher processing speeds

The new masterbatch counteracts this: By significantly stabilising the melt flow, it improves the production process so that Higher processing speed can be realised become. It also increases the lustre and reduces clouding.

PFAS, also known as „eternity chemicals“, are problematic due to their high resistance in the environment. They are used in many industrial applications, but are increasingly being under regulatory control, as they cause both health risks and environmental pollution. The new EU regulation from September 2024 provides for comprehensive bans on PFAS, which will affect plastic packaging, among other things, from October 2026.

Source: Polyvel