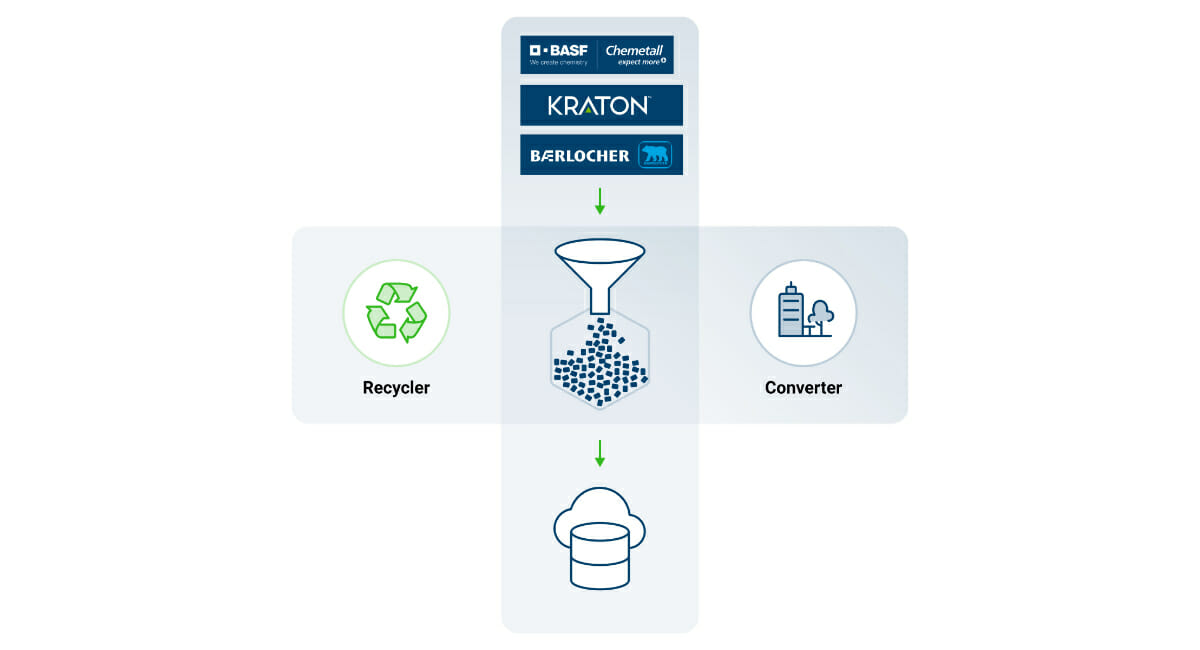

A new digital service developed by Plastship in collaboration with Kraton, Chemetall and Baerlocher provides an overview of the interaction between recyclates and additives. With the help of the additives offered, the properties of recycled plastics can be improved and thus used for higher-value applications. The new addition to Plastship's offering, the Additive Selector on the company website, combines data on recyclates and additives to facilitate the use of recyclates.

Plastship, a European platform for the procurement of recyclates, is expanding its range and making it easier for plastics processors to use recyclates in applications by refining plastic recyclates with additives from selected partners. In addition to recycling-orientated product design and precise sorting technology, the Improving material quality This is of crucial importance in order to increase the utilisation rates of recyclates in high-quality applications in the future. Performance-enhancing additives help to improve the processability of recyclates and preserve the materials for additional reuse cycles.

Effects of additives at a glance

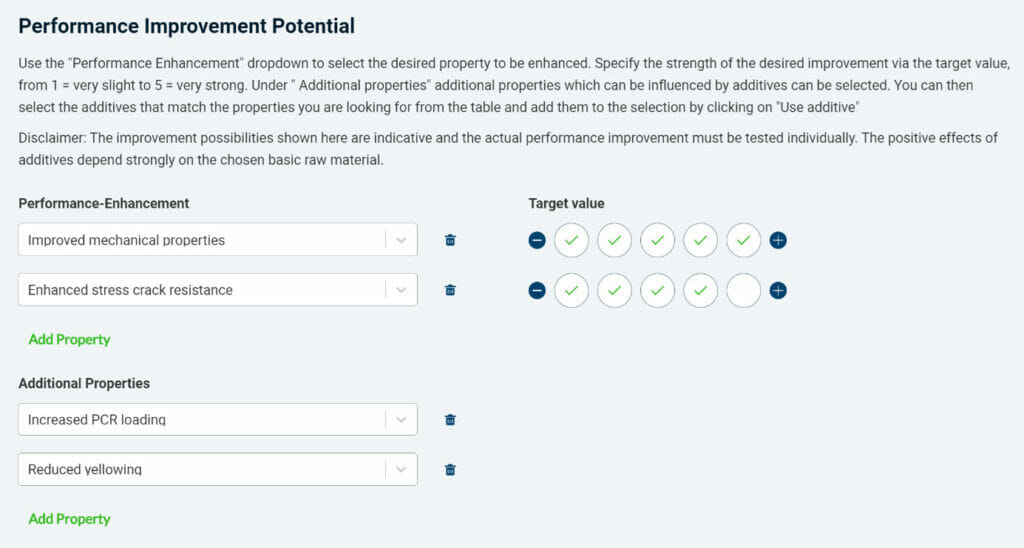

The Additive Selector on the Portal from Plastship provides an overview of the effect of various additives and offers manufacturers and users of recycled plastics Indications of potential performance improvements through the use of additives. „The new function offers our customers a variety of additives to choose from that can improve the material quality for a selected recyclate and predicts the properties of the material-additive combination,“ says Andreas Bastian, Managing Director of Plastship.

The Additive Selector includes a comprehensive approach to Involvement of customers. All enquiries via Plastship are processed directly by the additive partners. In order to achieve the specific performance targets and individual requirements for the end application, it is possible to contact specialists from the additive manufacturers via the Additive Selector.

Added value for the circular plastics economy

One of the biggest challenges in the processing of recycled plastics and therefore an obstacle to the use of recycled materials are fluctuations in the performance and quality of the materials. Material quality in plastics recycling depends to a large extent on the quality of the source material and the type of recycling process. It is extremely important for a circular economy that recycled raw materials can be reused. Additives can play a decisive role when it comes to modifying recycled raw materials so that they meet the application requirements and enable them to be utilised. The value of recycled materials can thus be increased and their recyclability guaranteed.

„By combining business intelligence from two quite complex areas - the effect of additives and data on recycled plastics and the choice of a digital approach, the Additive Selector and the partners involved offer valuable guidance to all manufacturers and users of recycled plastics. The collaboration opens up possibilities for material flows that previously did not fit a specific application and enables improved recyclate quality and new recipes. In the future, the data-based approach will help to visualise opportunities, predict additive effects and recommend solutions based on best practices and previously solved challenges in recyclate quality - to the benefit of the entire industry,“ says Bastian.

SourcePlastship