When Josef Pöppelmann founded a cork stopper factory in a chicken coop in Lohne 67 years ago, he could not have foreseen the rapid development this business would undergo. Today, Pöppelmann GmbH & Co. KG is one of the leading plastics processors in Europe, producing high-quality functional parts and packaging - even under cleanroom conditions if required.

Whether bottle caps, protective elements, plant pots or laboratory vessels - the Pöppelmann Group has been combining tradition and progress in its product portfolio for almost seven decades. Founded on the basis of a simple business idea, the family-run company is now one of the leading manufacturers in the plastics processing industry.

With its five production sites and over 550 injection moulding machines, thermoforming systems and extruders, Pöppelmann is one of the most important employers in the region and supplies customers in more than 90 countries. More than 2,000 highly qualified employees work for the success of the company worldwide.

The path from cork to plastic

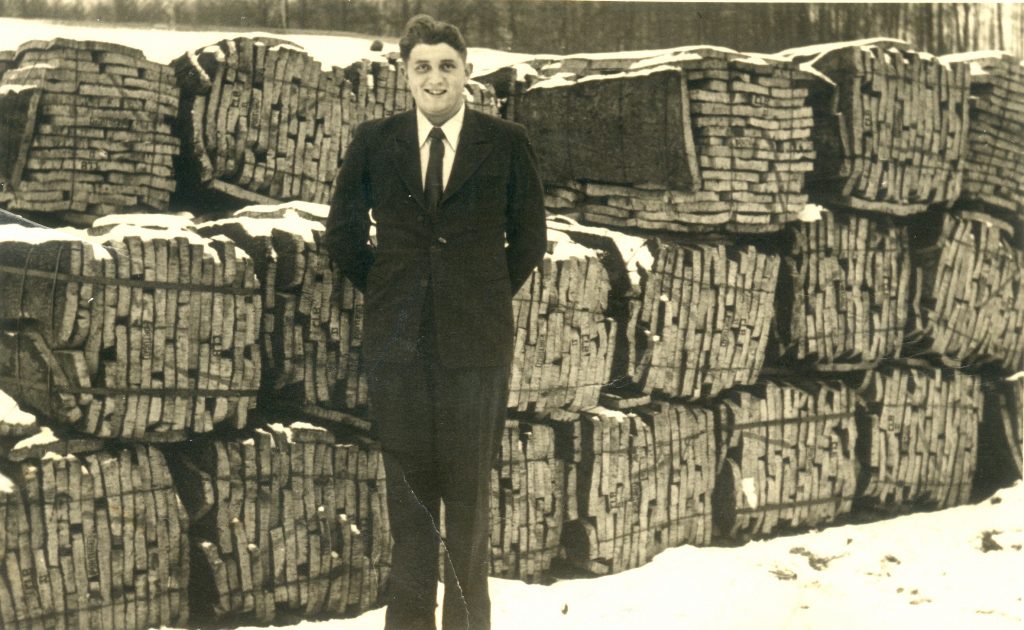

In February 1949, the brothers Joseph and Hubert Pöppelmann one „Application for authorisation to open a cork factory“ to the town council in the district of Vechta in Lower Saxony. „The first products were closures made of cork from the cork oak, produced on a hand cutting machine for bottle corks,“ explains Torsten Ratzmann, Chairman of the Management Board since the beginning of 2016. „An old chicken coop on his parents“ farm in Brockdorf near Lohne was converted for the young entrepreneurs".

The still young company entered the plastics era in spring 1955 with the purchase of an injection moulding machine at the „Deutsche Industrie-Messe Hannover“. Norbert Nobbe, who manages the Pöppelmann business together with Ratzmann, explains: „Pöppelmann thus laid the foundations for today's four business areas.“ In the years that followed, toolmaking and the company's presence on the international plastics market were strengthened.

The introduction of the KAPSTO brand programme for caps and plugs was followed by the first technical injection-moulded plastic parts with the K-TECH programme and a few years later by the TEKU programme of plastic plant pots.

„The company has steadily expanded its innovative capacity and tailored its plastic products to the diverse needs of various industries,“ says Torsten Ratzmann, summarising the development of the Group's first three divisions.

[infotext icon]Pöppelmann - Milestones in development1955 First plastic injection moulding machine.

1957 Development of KAPSTO - caps and plugs for industrial applications.

1962 Introduction of the K-TECH programme - high-precision technical injection-moulded plastic parts.

1966 First foreign branch in France (Mulhouse, Rue du Rhin).

1970 The TEKU programme starts with the production of the first flower pots.

1998 Development of FAMAC - functional parts and packaging.

2004 Commissioning of clean room production.

2007 Pöppelmann Plastics USA opens a site with the TEKU division in Claremont, North Carolina.

2014 Pöppelmann FAMAC expands its cleanroom capacities. [/infotext]

Functional parts and packaging as fourth business division

With FAMAC the plastics experts have been running a fourth business division for packaging and functional parts used in the food, pharmaceutical and cosmetics industries as well as in medical technology since 1998. In addition to a wide-ranging standard programme, special solutions are available at economical conditions.

„Customers receive everything from development to series production from a single source and benefit from the resources, partners and contacts of the Pöppelmann Group,“ explains Engelbert Rechtien, who heads up sales at FAMAC. A dedicated project manager ensures close internal and external coordination and is available to the client as a permanent contact throughout the entire process.

Injection moulded products from the clean room

The injection moulded products are manufactured to the highest standards in accordance with the rules of Good Manufacturing Practice (GMP). „Since 2004, we have been manufacturing laboratory vessels and other products as well as complex assemblies for the medical and pharmaceutical industries under cleanroom conditions, including the respective primary packaging if required,“ emphasises Engelbert Rechtien.

Production takes place in two clean rooms in accordance with DIN EN ISO 14644 class 7 and GMP standard - C with a separate air conditioning and filter system. A certified quality and hygiene management system provides additional safety.

Employees wear special protective clothing and are trained accordingly. Regular checks ensure a particle and germ content in accordance with the implemented standards.

„Especially for products for the pharmaceutical industry and medical technology, the highest demands are placed on technology and quality from the start of component development to the release of the tool design, criteria that we at FAMAC implement reliably and always in the interests of the customer thanks to our expertise,“ adds Rechtien.

The injection moulding machines produce from outside into the clean room. If necessary, they can be disconnected for use in other production areas. The moulds are manufactured in a separate area of the Pöppelmann mould construction department.

This mould construction department has been responsible for the design of injection moulds and thermoforming moulds for all business areas for over 50 years and today comprises around 130 mould makers and mould designers. The spectrum of injection moulds ranges from standardised contour inserts to stack moulds.

Faster to series maturity with rapid prototyping

The in-house toolmaking department also enables working with Test and pre-series moulds. Thanks to rapid prototyping using stereolithography, selective laser sintering and PolyJet matrix technology, Pöppelmann is able to provide customised test samples in different materials at an early stage of development. „When we receive an enquiry for a product, we not only develop a drawing from it, but also produce a prototype within hours that the customer can touch, test and understand,“ says Engelbert Rechtien, explaining the principle.

The samples created by Pöppelmann using 3D printing are already „so close to the final solution that the customer can test its functions under realistic conditions. This allows them to immediately recognise whether their expectations are met and which errors may still need to be eliminated,“ the sales manager continues.

After close coordination with the customer, the process capability of the component is scrutinised with regard to the application requirements. The aim of this functional test is always series production readiness. Only when this has been achieved does the production of a mould for series production begin.

Multifunction through modern equipment

Pöppelmann FAMAC uses modern machinery with clamping forces of between 250 and 13,000 kN for the production of packaging and functional parts. Equipped with injection moulding machines in various dimensions and designs, it enables economical production through the Two-component injection moulding. „This process allows us to combine different plastics with contrasting properties into one component,“ explains Rechtien.

This allows hard and soft or reinforced and slip-optimised plastics to be combined. Multi-coloured parts and the form-fit connection of two non-adhesive plastics are also possible. „If two conventional standard injection moulding machines are used for this, the two-component part is created by transferring the pre-moulded part to the second machine for the second plastic,“ says Engelbert Rechtien, describing the process.

The next stage is formed by injection moulding machines with two injection units for both materials. Here, the pre-moulded part is produced in the first mould station. The mould then opens and rotates on an index plate so that the pre-moulded part enters the second, enlarged cavity. The mould closes and the second plastic is injected. The product can be finished in a single process, eliminating the need for assembly and reworking.

Setting trends with innovations

By utilising new technologies, Pöppelmann regularly brings innovative packaging solutions to the market. It is not uncommon for the development and design process to result in a Award-winning solution out. FAMAC received the 2014 German Packaging Award for its Göffel snack cutlery, an alternative to conventional disposable cutlery.

„In order to offer our customers in the food industry the best possible conditions for success in the market, we at FAMAC focus on intuitive design, a customised, high-quality look and outstanding machine operability,“ says Rechtien.

With in-mould labelling (IML), Pöppelmann has an economical solution for decoration. With this type of decoration, the label is applied during the injection moulding process. A robot positions the printed plastic film (< 50 µm) in the mould. There it is fixed in place and back-injected with the container material. After the injection moulding process, the label and moulded part form an inseparable unit with a continuous surface. The process offers the advantage of significant time and cost savings. IML-decorated packaging can also be easily recycled.

Regionally anchored in the future

As in the days of Joseph Pöppelmann, who died in 1983, constant progress is still a core component of the company's philosophy today. With subsidiaries and branches in France, Spain, England, Denmark, Belgium and the Netherlands, Pöppelmann is present in plastics processing throughout Europe. What has remained are the down-to-earth attitude and the Loyalty to Lohne. The company, which has strong regional roots, has largely trained its own specialists since 1956.

„In times of increasing automation, it is becoming more and more important to promote and develop highly qualified staff within your own company,“ emphasises Torsten Ratzmann.

Pöppelmann meets this challenge by training committed young people in the areas of development, machine tool construction, logistics and sales, as well as through Structured further training opportunities. „With currently more than 170 trainees, we are one of the largest training companies in the Oldenburger Münsterland region,“ says Ratzmann. In total, the company has trained over 1,200 young people in various professions in recent years. „Like all Pöppel men and women worldwide, they make a significant contribution to the success of the group of companies,“ says the Chairman of the Management Board.