With clipping machines, automation solutions and sustainable packaging concepts, Poly-clip System will be presenting itself at IFFA 2025 as a full-service provider for all sizes of business - from artisan production to industrial automation.

At IFFA 2025, Poly-clip System will be presenting its broad portfolio of clipping and packaging solutions - with Focus on automation, sustainability and process reliability. The range is aimed at companies of all sizes in meat processing and beyond, for example for poultry, cheese, plant-based products or pet food.

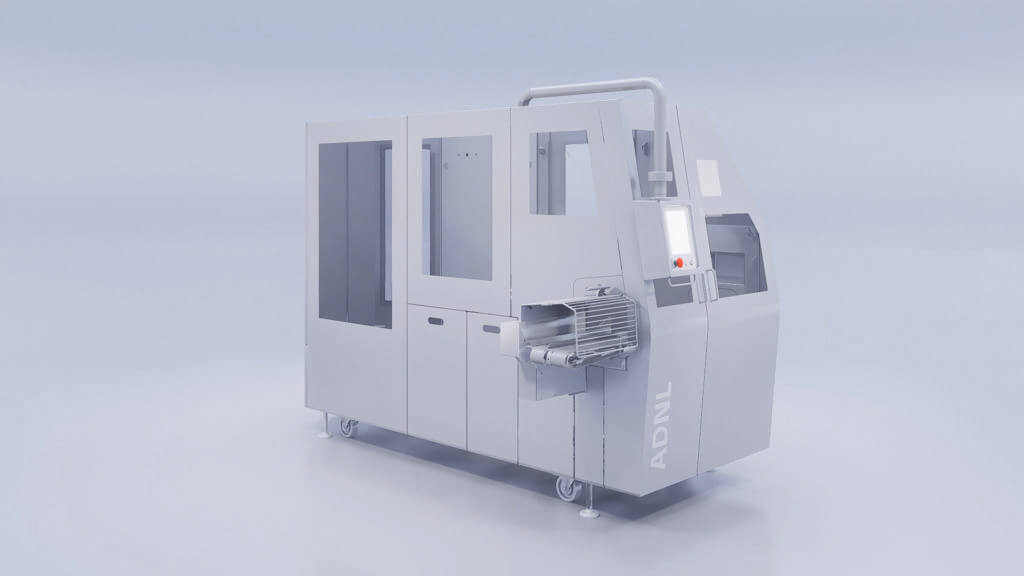

One highlight of the trade fair is the new ADNL machine, which takes care of automatic casing reloading. It significantly reduces labour costs and enables continuous production of up to two hours. A Operator can operate several machines in parallel - a clear advantage in times of a shortage of skilled labour. The extension is compatible with the FCA 120/160 and FCA 160 XL clip systems.

Automatic loading of smoke trolleys

Also new: the HSH 18 for automatic loading of smoke trolleys with horizontal sausages. Using camera recognition, it places products weighing up to 18 kilograms and measuring up to 1,200 millimetres in length precisely - without packaging bursts. Here too, unmanned operation significantly increases efficiency while reducing the physical strain on staff.

Further trade fair highlights:

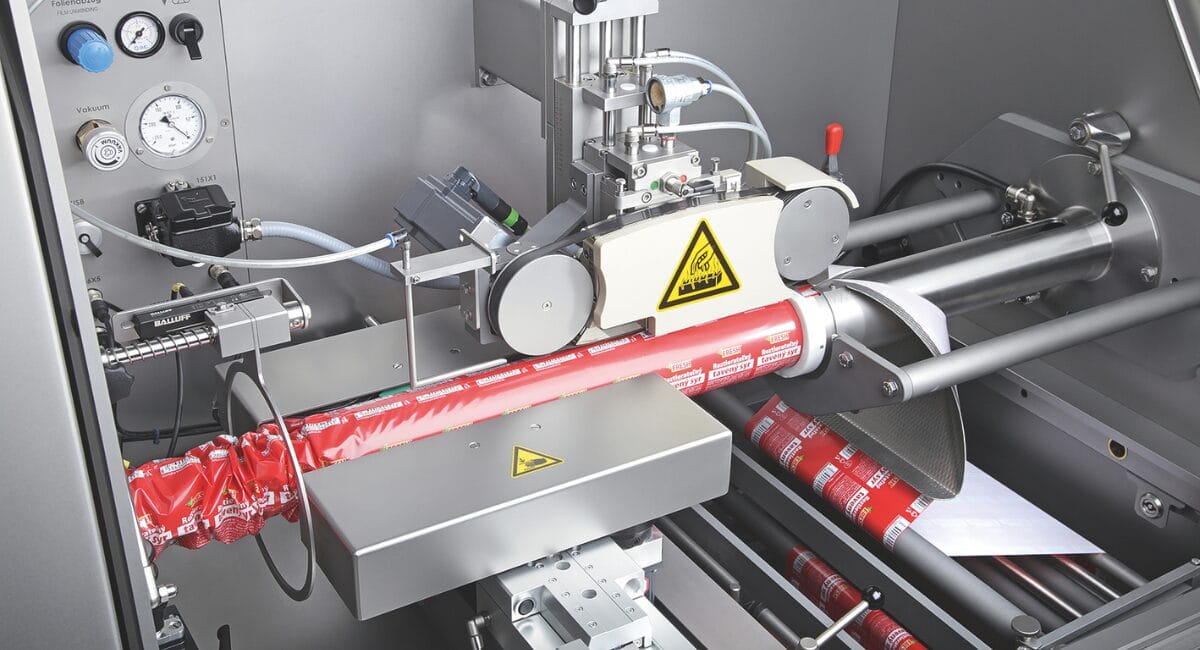

- TSCA 120 - Sealing clip machineDeveloped for sustainable snack packaging. With easy-opening aid, PVDC-free films and up to 100 times the running time per roll compared to classic casings. Ideal for small portions such as sausage, cheese or ready meals.

- ICA - Clipping machine for large calibre and shaped productsFor calibres up to 200 mm and 60 cycles/minute. The iris displacer enables precise portioning, ideal for ham, sausage sticks or air-filled moulded products.

- FCA 160 XL - quadruple clipper with maximum holding forceFor products up to 14 kg. The 2+2 clip system and the synchronised servo drives ensure high performance (up to 160 cycles/minute) and safety when processing heavy products such as roasts or cheese.

Flexible, automated, hygienic - for meat products and more

The IFFA portfolio from Poly-clip System is exemplary for the transformation of food processingThe focus is on higher efficiency, automation and process reliability - without losing sight of flexibility and hygiene. Sustainability also plays a role: for example through the Use of material-reduced flat film packaging.

Source: Poly-clip system

Poly-clip System at IFFA 2025: Hall 12, Stand D81