The packaging of smartphone „grips“, known as PopGrips, was a very labour-intensive and monotonous manual process at iClick. The US promotional products manufacturer now relies on the collaborative properties of two-arm robots, which successfully automate the processes.

With the PopGrip, a smartphone fits much better in the hand. The small round grip sticks to the underside and has a shaft that can be stretched like a bellows. Savvy marketers quickly recognised the potential as a first-class marketing tool.

The mobile advertising space is so inexpensive that it can be given away at trade fairs, events or via many other channels. Thanks to this momentum, the PopGrips have catapulted to become the most sought-after product from iClick, a Seattle-based provider of promotional products.

Final assembly and packaging process

Due to the growing demand, an efficient solution had to be found for customising and packaging. This involves the use of a bag labelled with the logo of the respective sponsoring company. PopGrip positioned on a customised printed card. This usually contains operating instructions and advertising content and is then packed in a plastic bag.

„The PopGrips were originally developed at a station manually inserted into the cards“We used to pack the boxes in one station and then transport them to another station to load them into an automatic packaging machine,„ explains Steve White, Executive Vice President of Production at iClick. “It was a labour-intensive process, and even with a team of four or more people, we couldn't keep up with demand."

In order to maximise the capacity of the packaging machine, those responsible started looking for possible automation solutions. After examining a variety of options, the two-armed ABB robot YuMi was the centre of interest.

Special automation solution

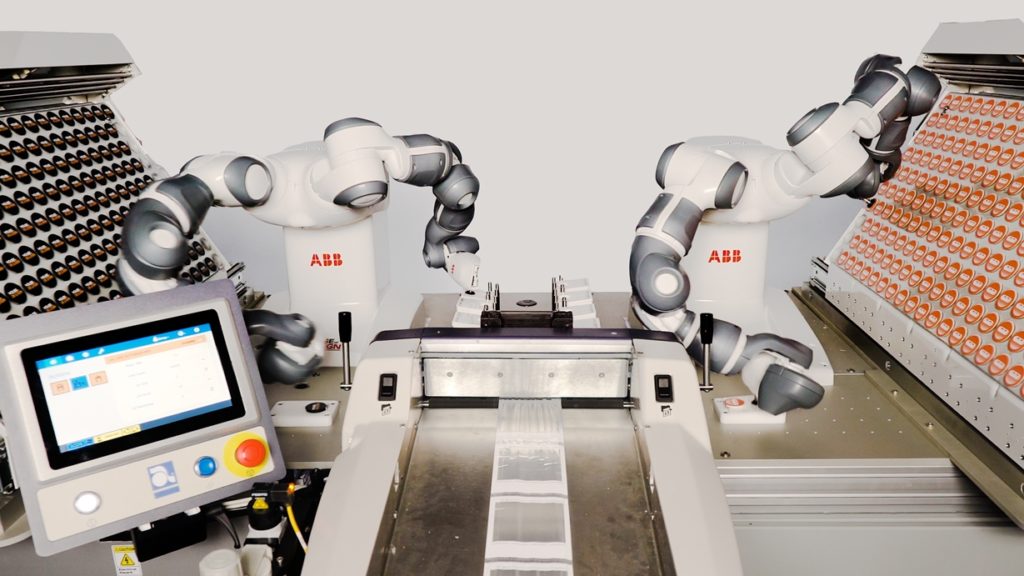

ABB recommended iClick to House of Design (HoD), an ABB systems integrator known for developing innovative robotic systems for unusual applications. The experts at HoD designed one station with two YuMi robots, which work in synchronisation with each other and insert and bag 24 PopGrips per minute. „ABB's collaborative robots proved to be the best solution,“ says Steve White. „With the two YuMis, we were able to Combine two manual processes into one seamless automated process."

The robots are positioned next to each other and perform the same tasks. Due to their proximity, all movements of their four arms and a total of 28 axes are carefully coordinated in order to optimise the Limited room capacity of the station to the maximum. HoD used the simulation software RobotStudio® from ABB to experiment with the movements of each robot arm and ultimately programme the optimum motion sequence.

„We use RobotStudio for system configuration and robot range studies, code tests and frequency calculations, among other things. The tool is also a powerful sales tool. It can be used to create simulations that illustrate our respective project vision. RobotStudio clearly shows the cycle speed and product flow so that the potential customer can be sure that we can actually solve their manufacturing problem,“ emphasises Brandon Schmidt, Vice President Automation & Robotics at House of Design.

[infotext icon]The House of Design can also score points with this efficient solution. The company markets the system under the name FlexBagger. It consists of one or two YuMi robots from ABB and the Autobag®-system from Automated Packaging Systems (APS). And it is now also used for other applications for assembling and packaging small products[/infotext].Optimised processes for packaging Popgrips

In the new system, one YuMi arm removes the PopGrip from the tray and places it on the intermediate mounting station. The other arm removes the card from the card station from the stack and pushes it into the groove between the bottom and top of the PopGrip. With the same movement, while still holding the card, it lifts the card and PopGrip unit and pushes it into the bag. The IO message is then sent to inform the packer that the part is in the bag.

„By combining two manual tasks into one automated process, the station does the work of four people and supplies the automatic packing system at full capacity,“ emphasises Chad Svedin, Project Manager at House of Design. „The system can also simultaneously on different orders The IO on the robot indicates which of several dedicated conveyor belts is carrying the bagged PopGrips.“

High safety standards

The collaborative properties and human-like dimensions make it possible to create a YuMi in the immediate vicinity of its human colleagues to place. In the event of a collision with an employee, it stops moving immediately. Restarting it afterwards is as easy as switching on a television by remote control. In the event of contact with a person, YuMi's magnesium skeleton covered with soft, rounded padding absorbs and cushions the impact.

This also eliminates the need for protective cages or enclosures, which are normally required for traditional industrial robots. This is an important criterion for use in PopGrip production. „The possibility of a open-plan production hall makes it easier for our operators to approach the station, refill card slots, pull rejects or perform other necessary tasks without interrupting the workflow,“ says Steve White.

[infotext icon]For iClick, the commissioning was the first experience with robot-assisted automation. The company installed a second, identical system shortly afterwards. Thanks to additional flexibility, the processes can be customised to handle, sort and pack many more iClick advertising products[/infotext].