Researchers at the University of Coimbra in Portugal have developed a new type of composite material that is made entirely from bio-based raw materials and is designed to achieve the performance values of fossil-based plastics. The results published in the journal Nature Scientific Reports study shows that cosmetics packaging could do without petroleum-based plastics in the future.

New combination of natural polymers and additives

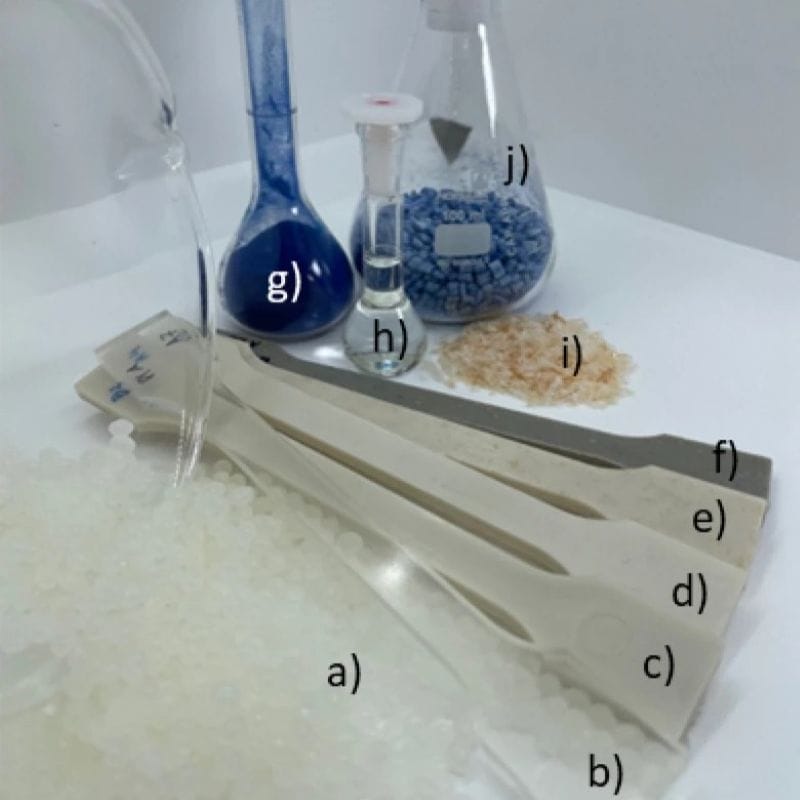

The team of material scientists from the University of Coimbra developed a multi-layer biocomposite made from PHBV (polyhydroxybutyrate valerate), PLA (polylactic acid), chitosan, plant-based plasticisers, essential oils and the colourant phycocyanin from microalgae. This combination has been specifically designed to meet the high requirements of cosmetic packaging - such as mechanical stability, temperature resistance, protection against moisture and hygienic safety.

The special feature of the development is that many bio-based plastics have so far only had limited resilience or lacked special barrier properties. According to the study, the new material should for the first time achieve similar values to polypropylene or polyethylene, which are currently considered standard materials in the cosmetics industry.

Focus on practical relevance

A decisive advantage: the researchers emphasise that the material can be shaped using conventional processing methods such as injection moulding. This means that it could theoretically be used in existing production facilities without the need for expensive retooling. This increases the chance that such sustainable packaging alternatives can be scaled up industrially in the medium term.

Sustainability meets functionality

Until now, cosmetics packaging has often consisted of composite materials that are difficult to recycle. With its development, the Portuguese research team wants to show that completely bio-based, compostable packaging is possible without having to compromise on functionality and product safety.

The additives used, such as chitosan - a biopolymer obtained from crustacean shells - or phycocyanin from algae, not only have ecological benefits, but also antimicrobial properties. This could be particularly relevant for sensitive cosmetic products such as creams or lotions.

Challenges on the road to the market

Despite the promising results, the researchers emphasise that there are still questions regarding industrial production and certification processes. The availability of individual raw materials and production costs must be optimised in order to be competitive with fossil-based plastics. The recyclability of multilayer materials in existing European collection and recycling systems also needs to be examined.

Prospects for the packaging industry

The study provides an important impetus for the packaging industry: it shows that high-performance bio-based alternatives to conventional plastics are technically feasible. This could open up new options for machine manufacturers and brand owners to fulfil the strict requirements of the EU packaging regulation (PPWR) and meet the growing consumer demand for sustainable packaging.

Source:

University of Coimbra: A novel fully biobased material composite for cosmetic packaging applications, published in the trade journal Nature Scientific Reports (2025). To the study