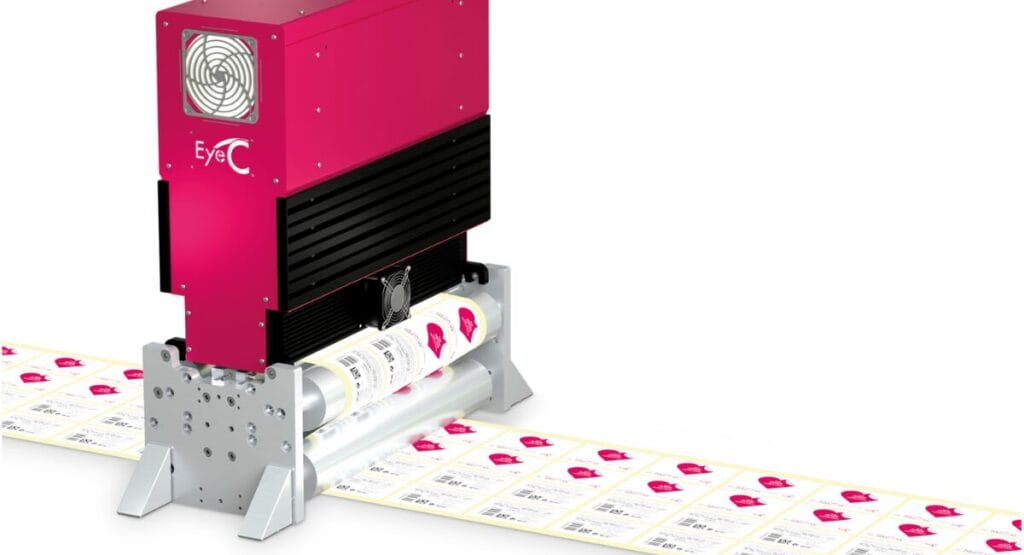

EyeC GmbH, a global provider of automated artwork verification and print image inspection systems, has equipped all inline inspection systems of the EyeC ProofRunner Web line with the world's first pre-trained AI.

EyeC's new AI solution marks a fundamental shift from simple error detection to content-based classification and analysis. The pre-trained system precisely recognises relevant quality deviations and automatically categorises them into four main defect classes: Material, Dust, Stains and Streaks - plus the special category „Other“. Additional classes are added in regular cycles.

The EyeC ProofRunner Web finds all errors with a high degree of accuracy, even hidden material errors in text fields can be filtered out. An essential The advantage of the new technology lies in the differentiation between critical defects that require immediate correction, such as colour stains and material defects, and irrelevant deviations such as dust particles or substrate inclusions. Although these are documented, they do not cause any unnecessary interruptions to production. The result: a significantly reduced number of pseudo-defects combined with higher processing speed.

Focus on sustainability

The use of AI-supported error classification is particularly relevant for companies that have to comply with requirements and regulations to reduce packaging waste and promote a circular economy - such as the EU Packaging and Packaging Waste Regulation (PPWR). The advanced image processing functions take into account different optical properties of sustainable materials, so that the system reliably distinguishes between acceptable surface irregularities and genuine defects in recycled substrates during inspection.

The training methodology is based on comprehensive Data sets from hundreds of thousands of images of actual print jobs. By analysing the extensive image library built up, EyeC's artificial intelligence learns to distinguish between defects that require attention and those that have no influence on the quality of the end product. The pre-trained system does not require an extensive training phase by the customer and is ready for immediate use.

„With our AI-based error classification, we are setting a new standard in the industry. While conventional systems only recognise defects, our AI understands them like an experienced expert and distinguishes them from irrelevant deviations. This enables our customers to carry out precise inline inspections at full speed while saving time and resources.“

Nico Hagemann, Director Product Management at EyeC GmbH

The AI-based error classification for the EyeC ProofRunner Web is available as a fixed component of the basic configuration and is as standard with every new system will be included. The expansion to other systems, including EyeC ProofRunner Sheetfed, will take place successively and in close coordination with OEM partners.

Source: EyeC