At IFAT in Munich, Strautmann Umwelttechnik will be presenting the JumboLoadBaler, a new machine for waste disposal technology. The baler processes cardboard, paper, octabins, film, PET bottles and beverage cans.

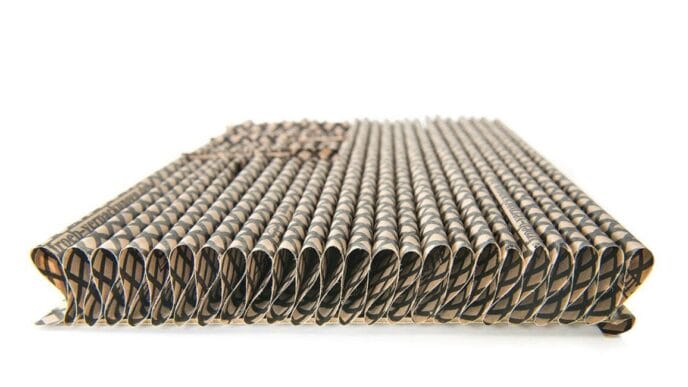

The JumboLoadBaler from Strautmann compacts cardboard, paper, octabins, film, PET bottles and beverage cans with a throughput of up to 800 kg per hour. It stands out in particular due to its large feed opening. This enables a Manual or automatic filling without any pre-shredding. This is unthinkable with conventional balers. Users save time by not having to pre-shred the material manually. It also only requires a footprint of 7 to a maximum of 11 square metres, making it ideal for companies that have limited space and want to dispose of waste directly at the source. This eliminates unnecessary walking distances and makes disposal more efficient.

The swing arm conveys the material to the rotor, which fills the bale chamber fully automatically and then compacts it into a 450kg bale with a pressing force of 600 kN. The bale is then tied manually. Thanks to various filling options such as a lifting and tipping device, conveyor belt, forklift or wall connection, the Integration into existing production processes can be realised without any problems.

„For us, the JumboLoadBaler is the perfect addition to the Strautmann range, which is always ready for use for direct carton disposal and makes work considerably easier for our employees. The combinable lifting and tipping device gives us an enormous time advantage over manual filling. The investment helps us to achieve sustainable disposal and profitable marketing of the bales produced. What was previously costly has now become a profitable business!“

Marcel Book, Logistics Manager ROFU Kinderland Spielwarenhandel GmbH

Source: Strautmann

Strautmann at IFAT: Hall A5, Stand 427/526