IWK is regarded as a pioneer in mechanical engineering and was the first company to invent a packaging system for filling and sealing tubes in 1893. This innovative spirit forms the DNA of the company, which today is known as a guarantor of quality in tube filling and cartoning systems. With energy-efficient technology, digital services and a modern packaging laboratory, it helps to conserve resources.

The IWK Packaging Technology based in Stutensee in Baden-Württemberg, is a globally active, medium-sized manufacturer of packaging systems. More than 550 people work in the IWK Group and contribute their many years of knowledge and expertise. In addition to the production facility in Germany, IWK also maintains a Plant in Thailand and service and sales centres across the continents. This year, the economically well-positioned company looks back on 130 years of eventful and moving history and looks forward to the future with excitement and joy.

The tube makes the difference

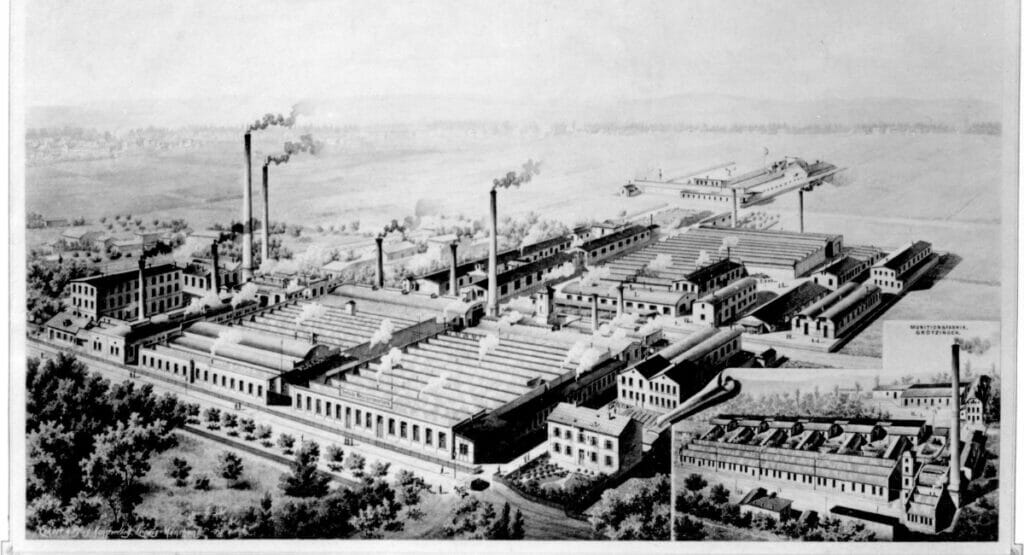

28 July 1893 is the founding date of today's IWK Group. On this day, Willem Karel van Dedem, Dutch Colonial Minister in The Hague, ordered machines and equipment from the company to fill and seal tubes for an opium factory in what is now Indonesia. The bottled product was an opium paste that was used as an analgesic ointment for wounds. was used. The idea of packaging pharmaceuticals and subsequently cosmetics was born and caught on.

At the beginning of the 20th century, the first luxurious department stores' palaces in Germany's metropolises turned shopping into an experience. Consumer goods were in demand, cosmetics were in high demand. And they had to be packaged. The Demand for corresponding machines increased accordingly, especially as the The cosmetics and pharmaceutical industries discovered the tube, previously used mainly for artists' supplies, as practical functional packaging. So-called beauty creams and, in particular, toothpaste, which came onto the market in Europe and the USA at around the same time, made the tube increasingly popular as a packaging material.

Courageous new beginning

130 years of company history are a time full of changes, innovations and disruptions. For example, civilian production was discontinued during the two world wars in the first half of the 20th century.

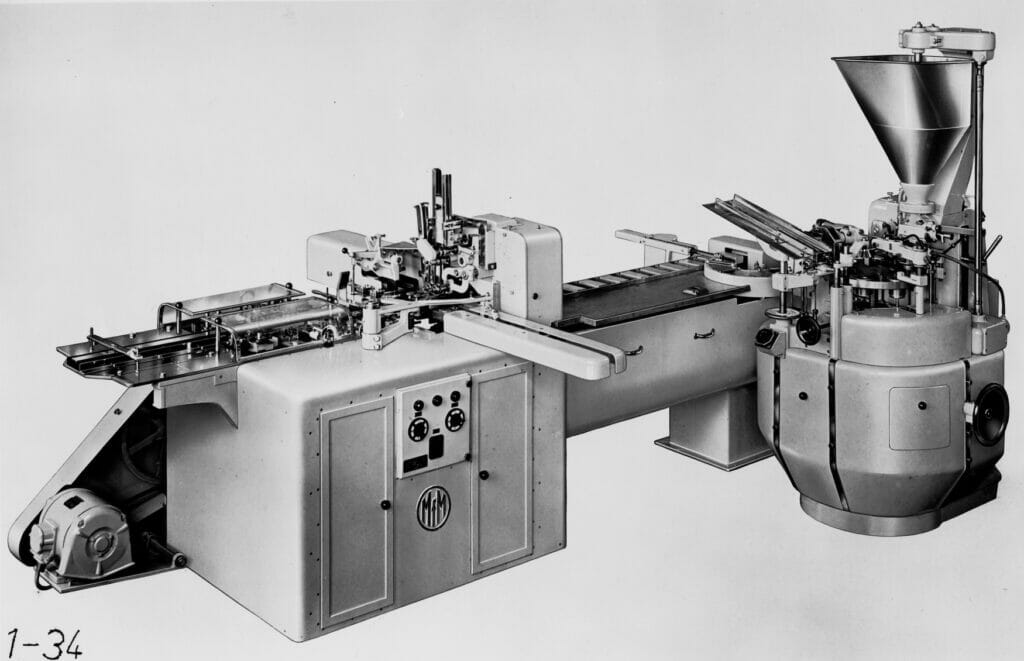

The entrepreneur Günther Quandt succeeded in making a new start. In Karlsruhe, the first steps were taken to resume the former civilian production programme piece by piece. One of the first orders for packaging machines after the war was a Tube filling and closing machine type T 1a. IWK achieved its breakthrough in the field of packaging machines in 1955 with the development of the first fully automatic packaging line for tubes, consisting of the tube filling and closing machine TF 2 and the cartoning machine K 4, for filling toothpaste and for packaging in the folding box.

A strong brand

The economic miracle at the beginning of the 1960s in Germany brought growth and prosperity - also in Karlsruhe. The range of goods on offer expanded, and with it manufacturers' expenditure on design, packaging and advertising. Good for the IWK. In the 1960s, there was hardly a Cosmetic, pharmaceutical, bakery or confectionery product that is not filled or packaged by IWK machines was.

In 1970, KuKa GmbH merged with IWK to form „Industriewerke Karlsruhe Augsburg AG“ - IWKA for short. One The company experienced a sustained growth spurt in 1979 when it moved from the centre of Karlsruhe to Stutensee-Blankenloch, nine kilometres away. Today's company headquarters were built there, with a production area of 11,000 square metres and 8,000 square metres of administrative space. In the 2000s, IWK introduced cycle assembly, which led to an increase in production capacity. This led to an increase in productivity and larger quantities for tube fillers and cartoners.. The sale followed in 2007 and IWK was managed under the umbrella brand OYSTAR. Since 2013, IWK has been part of the globally active ATS Corporation based in Canada and is now a globally operating company.

Great experiential knowledge then and now

„The technical expertise gained over a century from thousands of high-quality packaging systems for filling, sealing and cartoning makes IWK a solution provider with a wealth of experience and a reliable and competent partner. Regardless of which products require a suitable packaging solution, IWK manufactures and installs individual systems or entire turnkey lines that are precisely customised to the respective customer requirements and run reliably.“

Dr Heinrich Sielemann, President of the IWK Group

The IWK experts have mastered the complex technical processes involved in packaging sensitive products from numerous industries. The packaging expertise they have acquired over the decades is the basis for their success. The Packaging systems are mainly used in the pharmaceutical and cosmetics sectors and for food and industrial applications. Incidentally, it was also IWK that realised the technical solution for exact stripes in toothpaste.

Modular for many applications

The portfolio of modular packaging systems is broad. Everything is possible, from entry-level to high-end versions. IWK has solutions in its programme in which the Format changeover completed within a few minutes. The changeover times, for example for changing packaging sizes and formats, are therefore short and the productivity of the production lines is therefore high.

Collaborative robots, cobots, can be used upstream and downstream and expand the automation of packaging processes. With the Integration of cobots into production IWK was the first mechanical engineering company to do pioneering work in its field together with the employers' liability insurance association. Today Cobots have become an integral part of uninterrupted production. The IWK FP 64 packaging line with TZC tube feeding system and depalletiser cobot was awarded the German Packaging Prize in 2017.

„With the market launch of the newly developed Toploader TL cartoning machine, IWK is combining many technical innovations. The system is designed for the gentle packaging of sensitive pharmaceutical and medical technology products in complex carton structures“, explains Dr Heinrich Sielemann. The compact design enables flexible packaging in the tightest of spaces and therefore requires 30 per cent less space than comparable packaging systems on the market.

Sustainable in many areas

Sustainability and resource conservation are important issues by which companies around the world are measured. Successful entrepreneurs have certainly already paid attention to economic efficiency and therefore sustainability in the past. Comparable standards, such as the EcoVadis label, according to which IWK is certified, have only recently been introduced. The company takes important criteria into account when developing packaging systems, such as the Minimising energy consumption, the possibility of processing new types of packaging materials and taking all aspects of recycling into account. One specific example here is the reliable filling and sealing of recyclable paper tubes. „In general, packaging will continue to be a key differentiator for brands. Due to consumer pressure and legislation, packaging will become more sustainable,“ emphasises Dr Heinrich Sielemann.

The company is also looking for and finding ways to conserve resources digitally. Digital services bring customers and experts together in real time, which reduces travel and thus CO2-footprint reduced. The myIWK customer portal shortens communication channels and speeds up services.

Change as a challenge

Innovations are the key to first-class technical solutions. This applies in particular to ever more extensive customer requirements and applications with special properties. Experts at the IWK Packaging Competence Center PAC2 provide far-sighted advice and guide customers safely through the optimisation of their existing packaging or their new development. Thanks to their many years of expertise in mechanical engineering, IWK engineers are able to find a customised packaging system for all technical requirements.

„We will see some changes in our industry. The topics of sustainability and energy efficiency will continue to challenge us and drive our developments.“

Dr Heinrich Sielemann

This pioneering spirit, combined with in-depth expertise and reliable service, has been appreciated by IWK customers worldwide since 1893.

More news from the magazine

Translucent paper seal labels for pharmaceutical packaging

Packaging machine manufacturer in flow

Powerful automation for mills

Decentralised signal processing with the Schmersal Safety Fieldbox