Companies from the Schwäbisch Hall district have decided to enter into an unusual cooperation in light of the coronavirus crisis: Optima is supporting the company Wrapping Solutions in the production of protective masks.

Wrapping Solutions from Rosengarten near Schwäbisch Hall specialises in this, Interior fittings for cars to produce. The company has now made its decision, Mouth and nose protection masks to be produced. Since 23 March, 20 workstations have been Maximum 24,000 masks per day sewn. The long-term aim is to expand to 40 sewing workstations. The aim is to produce in two-shift operation.

„According to estimates around 14 million protective masks per day in Germany needed,“ says Managing Director Wolfgang Schaller.

Folding device increases production capacities

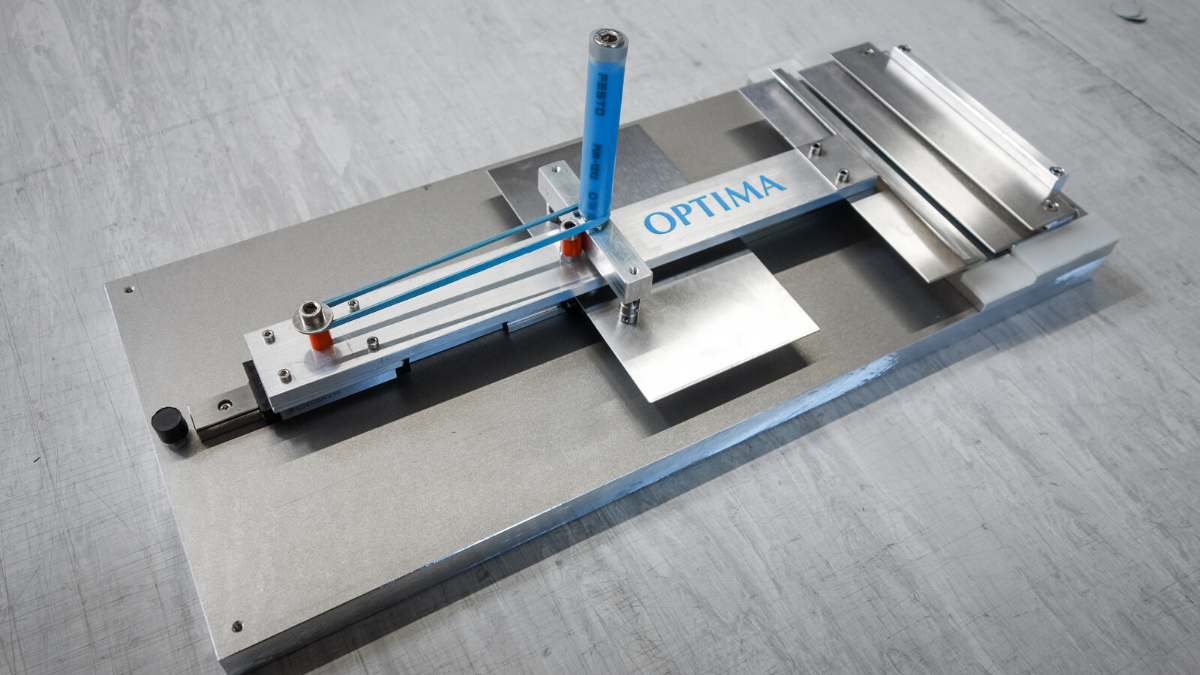

When optimising the work processes Optima now supports the operation. „We have a Device built for folding the face masks and was successfully put into operation at Wrapping Solutions on 31 March,“ reports Werner Volk, which is part of the Life Science of the Optima Packaging Group is responsible for new applications.

This happened previously by hand and proved to be a bottleneck in production. The machine-produced fabric blanks are folded in the station and on both sides with ultrasound welded together. In the final step, loops are sewn onto the masks.

„We are very pleased about the technical support from a special machine manufacturer like Optima“, says Schaller. This is a first step towards speeding up the production of the masks. In order to further increase the company's production capacities, talks are currently underway about possible automation of this process.

Source: Optima Packaging Group