In future, machines from pester pac automation will make information available directly in the browser with the help of atvise SCADA from Certec using pure web technology: With two innovative software modules, the packaging machine manufacturer from the Allgäu region provides solutions for previously unfulfilled requirements of its customers and itself.

As an initial situation, pester pac automation GmbH, Wolfertschwenden, had requirements in two different areas due to different prerequisites, which the company was unable to fulfil with the tools available to it:

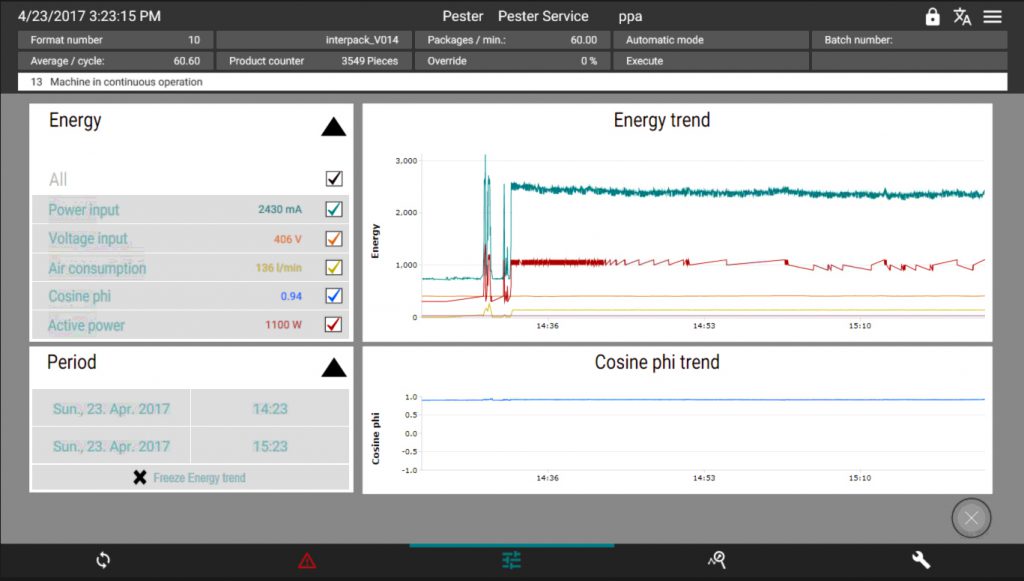

- For some time now, there has been an internal need to implement a log function for machine and operating data for analysing and troubleshooting, which records signals and variables over a longer period of time, saves them and makes them available for display in both list and diagram form.

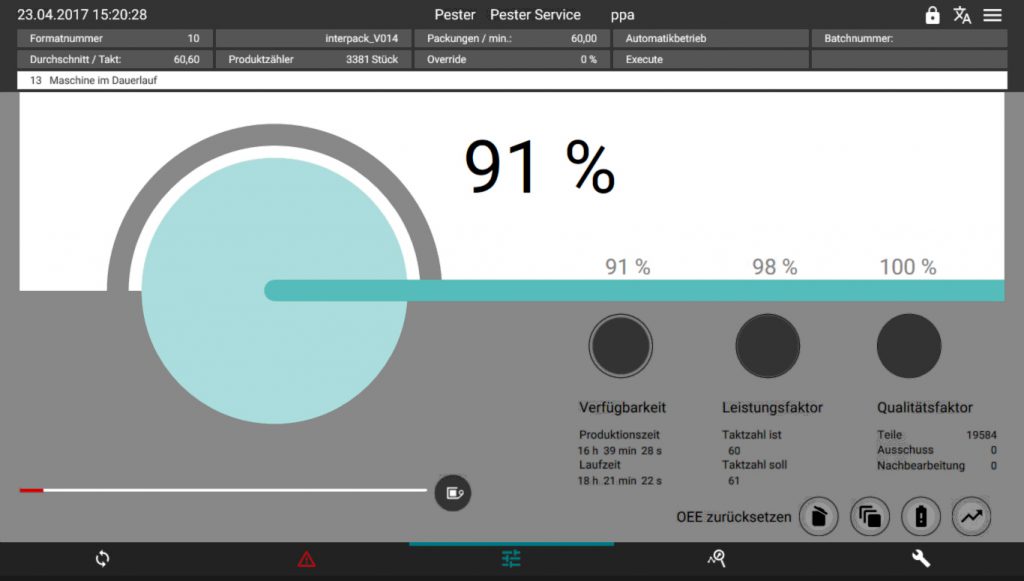

- They wanted to provide their customers with added value in the area of key production figures in the form of an OEE (Overall Equipment Effectiveness) analysis. The balancing of machine and production data is becoming increasingly important, and machine utilisation and high productivity are becoming an absolute must, particularly as a result of globalisation.

It was therefore extremely important for pester pac automation to be able to analyse the not only for new machines but also to enable these functionalities to be retrofitted to existing machines and systems.

[infotext icon]As some older machines are not equipped with an industrial PC, atvise SCADA was used to establish a connection to the control system, allowing key OEE figures and logged operating data to be visualised and analysed in the web front-end[/infotext].Solution approaches

„The two topics of process data logging and the visualisation of productivity indicators are always hotly debated in various industries and are extremely interesting from the point of view of both plant operators and machine manufacturers,“ explains Tobias Weber, Key Account Manager at Certec EDV GmbH, Eisenstadt (Austria).

A technical evaluation at pester pac automation led to the conclusion that both requirements could not be met solely by configuring and parameterising the product due to its complexity. atvise SCADA The product's openness and flexibility mean that the sometimes high, SCADA-atypical requirements can be fulfilled by application-side developments.

In both applications, the OPC UA server already present in the pester pac machines serves as a data source, from which the data is written to the internal database of atvise SCADA and from there made available to the applications (OEE evaluation).

„We were particularly impressed by the flexibility of atvise SCADA,“ emphasises Ralf Abler, Director of Electro and Software Engineering at pester pac automation GmbH.

As usual with atvise, the front end of the application is displayed in any browser using pure web technology, regardless of the platform or end device. In future, pester pac customers will therefore be able to use the applications not only on the panel directly on the machine, but also in the control centre and on mobile devices such as smartphones or tablets. This is a real added value, especially for the OEE application, and with regard to trend topics such as mobile applications like „bring your own device“ opens up new opportunities for machine operators, production managers and quality managers, for example.

Development projects

The atvise SCADA engineering tool, atvise builder, is an essential tool for the successful design and timely completion of such development projects. The combination of OPC UA technology at the core of the product and end-to-end object-orientation makes it possible, without web programming knowledge create a web application through simple configuration and parameterisation work, as the necessary HTML code is automatically generated by atvise builder. Typical SCADA functionalities such as alarming, historisation, dynamisation, etc. are available in a user-friendly way via drag & drop, as is the globally unique option of operating this system in a hot-standby redundancy in pure web technology.

If, as in the case of the development team at pester pac automation GmbH, Javascript skills are available, these advantages can be utilised even further thanks to the integrated and openly accessible scripting engine. This means that solutions can also be realised that lie outside the pure parameterisation and configuration options. In addition, very efficient engineering processes can be realised by using these technologies and the associated possibilities in atvise SCADA. This reduces the effort involved in day-to-day project business and leads to an early return on investment.

To keep the time to market for the two applications as short as possible, the company also launched Two separate development projects, whose course could hardly have been more different: While pester pac automation GmbH developed the OEE module exclusively in-house with the help of joint training sessions and workshops, the majority of the development of the logging functionality was outsourced to the applications department at Certec EDV GmbH. The wide range of joint activities resulted in a close partnership within a few months, during which the expertise of the two development teams - process know-how on the one hand and SCADA/web programming knowledge on the other - increasingly merged and the results can now be seen in the form of the two software modules launched on the market. Certec EDV GmbH proved to be not only a product supplier, but also a valuable partner and solution-orientated full-service provider for the machine manufacturer.

„Thanks to the large overlap in expertise in the development teams and the customer requirements for the machines, plus the possibilities and flexibility of atvise SCADA, intensifying the collaboration and further joint product developments are only a matter of time,“ say the two companies. Tobias Weber (picture) and Ralf Abler agree.

Looking ahead

The end of the co-operation and joint developments is far from foreseeable with the completion of these two joint projects: The next step planned is to develop a new product based on standard products. Hardware solution that enables a retrofit for old systems without a software interface. Products from Certec's parent company bachmann electronic GmbH are being evaluated as a potential solution for this. The hardware should receive the data either as a fieldbus participant or by means of simple digital/analogue I/Os and then make it available in the form of the logging application already developed. Middle-aged„ systems that already have an OPC DA server can be retrofitted with the already available software solution anyway using the OPC DA client interface in atvise SCADA.

[infotext icon]Certec EDV GmbH developed the world's first fully equipped web HMI and SCADA system in pure web technology. The membership of the subsidiary of the globally active bachmann electronic GmbH in the OPC Foundation emphasises the company's philosophy of supporting open international communication standards[/infotext].