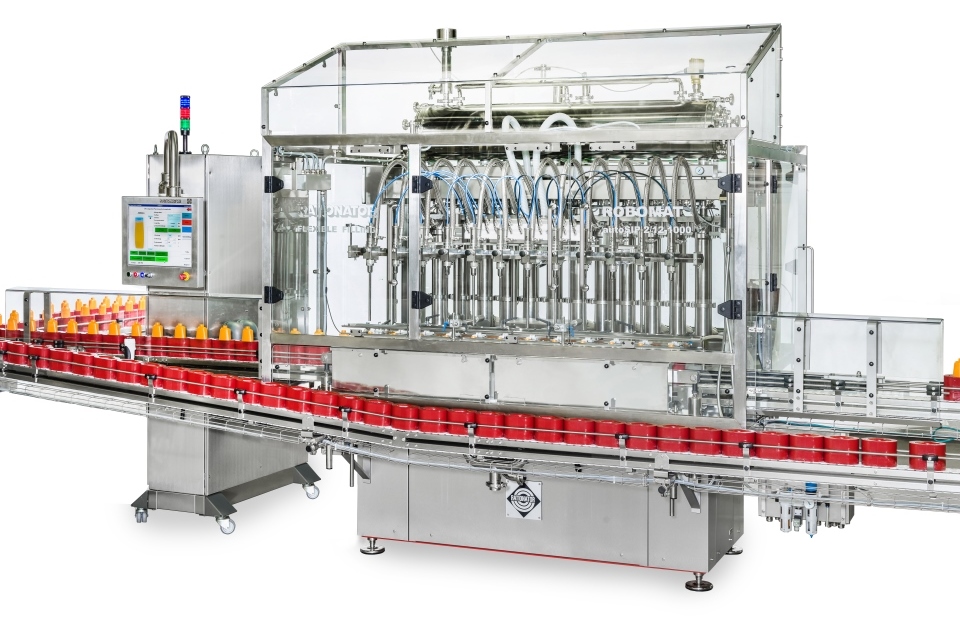

Rationator Maschinenbau GmbH from Hillesheim will be presenting its flexible, series-produced RATI Puck Line filling systems with integrated RATILIGHT transport mould system at FachPack 2019. This unique combination offers customers many advantages.

The use of RATILIGHT pucks ensures safe bottle transport, even with unstable bottles, so that the bottles can be transported safely. Process reliability of the line is considerably increased.

In addition, thanks to the standardised transport mould size, only one Minimum of format parts required. Format parts are only used on the capping machine and can be changed quickly and easily. The bottle unscrambling and filling machines work exclusively without format parts.

The current expansion of the puck range to include RATIMILLED pucks offers a solution for Special, sophisticated bottle formats. The specially developed and manufactured transport moulds are optimally matched to RATI Puck Lines thanks to their special design and reduced weight.

Rationator at FachPack 2019: Hall 2, Stand 207