For over 50 years, Rationator Maschinenbau GmbH in Hillesheim near Nierstein in Rheinhessen has been dedicated to the precise filling of low-viscosity, pasty, foaming and highly viscous liquids. Finally, all bottles, which can have a wide variety of shapes, are securely closed with exactly the right closure.

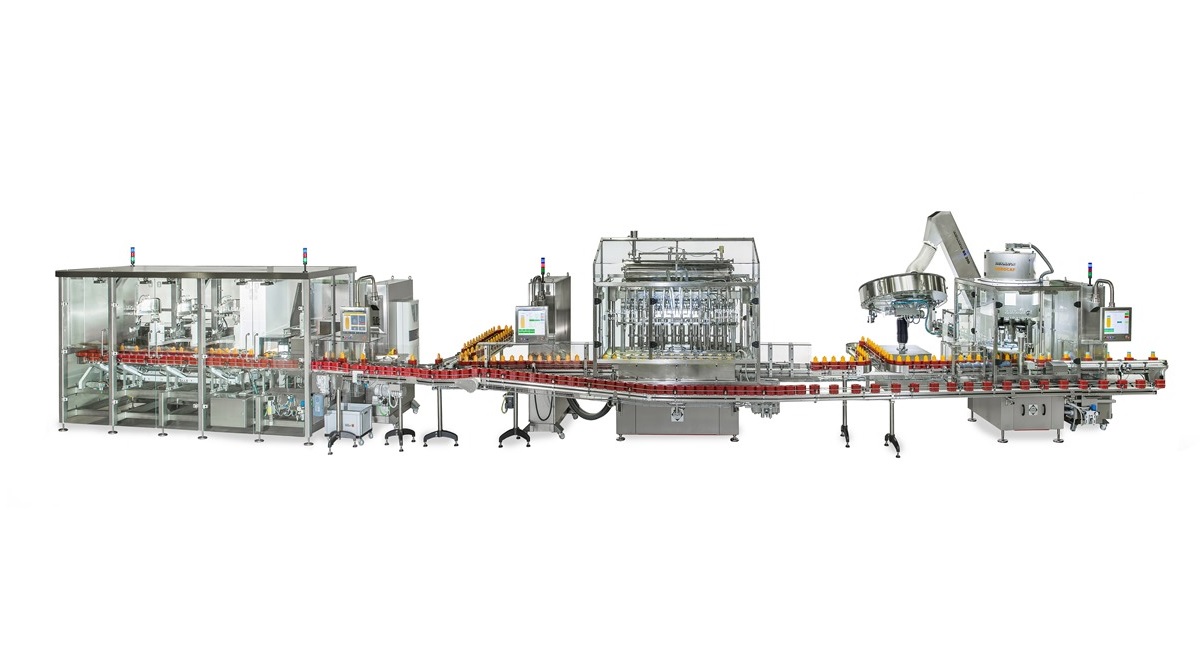

All good things come in threes: A complete filling line consists of three modules. First comes the Bottlemat Robot, with which the plastic bottles to be filled are erected and placed in Ratilight Puck transport moulds. This is followed by the Robomat filling machine. Finally, the servo-controlled Robocap capping machine closes the filled bottles.

All machine parts are made of Stainless steel to fulfil hygienic requirements. From installation to filling and sealing, the Ratilight Puck transport mould system. The system developed by Rationator can be used for almost all bottle formats and shapes for safe and cost-efficient transport.

The art of placing bottles

Under the designation „Bottlemat Robot“ the company produces its flexible, high-performance and robot-assisted Bottle unscrambler. It is, so to speak, part one of a complete flexible filling line. The system can fill plastic bottles in the Sizes from 20 to 1,000 millilitres are processed. The system automatically erects the bottles, orientates itself to their shape and places them in the integrated transport mould system.

A few additional components are required to make the Bottlemat Robot fit for its task. The Integrated bottle container Bottle Pool stores the bottles and feeds them automatically onto the gripper belt of the Bottlemat Robot via an ascending conveyor. The Integrated Bottle Check camera system recognises the exact position of the bottles and informs the robots with vacuum grippers.

Depending on the output quantity, the bottle unscrambler can be equipped with two, three or four gripper robots. The computer-controlled grippers pick up the bottles and place them in the available Ratilight Pucks to the safe onward transport to the filling machine.

Precise filling

The servo-controlled Robomat filling machine automatically fills thin to thick or foaming products off. A decision is made on the task to be performed CIP or SIP process is to be cleaned automatically. AutoCIP means automatic cleaning (cleaning in place) using an integrated cleaning box. In the autoSIP process (sterilisation in place), the product-carrying parts are sterilised with hot steam in a closed circuit. An external CIP system can also be integrated on request.

Depending on the application rate, the Filling stations with eight, twelve or 14 filling points equipped. The size of the filling pipes also depends on this. Depending on their task, their outer radii are between three and 18 millimetres. The filling material in the integrated product container is filled into the bottles via a dosing piston.

To ensure an uninterrupted supply, additional filling material is stored outside the filling machine in a Storage tank stored. The control of the external product pump is integrated into the system.

The entire dosing process is servo-controlled and runs with highest filling accuracy, such as foaming liquids. Here, the filling nozzle dips into the container and moves upwards at the filling level when dosing the set dosing quantity. Or when filling flammable media. This is where the Atex concept for safe explosion protection comes into play.

Servo-controlled locking

The Robocap or Robocap DP can be used to A wide variety of closures onto the filled bottles. While the Robocap capping machine applies the A wide variety of press-on, screw and alignment fasteners the Robocap DP is designed to process Closures for dosing and spray pumps as well as standard closures. With the help of a so-called cap check, the position of the caps is precisely recognised and aligned with the bottle accordingly.

The company offers several solutions for stocking and feeding closures. In all cases, these are Feeding conveyor, which differ in size, type of cap and desired storage volume. In addition, the Cap Sorter is a Disc sorter for round and moulded closures ready. While the Pump Cap Sorter sorts dosing and spray pumps as well as standard caps, the RF round conveyor as a vibration sorter sorts syringe inserts, fittings and special caps.

All Robocap capping machines work with servo-controlled capping spindles and Freely selectable closing direction. Depending on the output quantity, you can choose between four, six or eight spindles for the number of capping spindles.

This is based on Optimum capping programmes for a wide variety of closure types. All programmes are stored in each machine and can be called up via the monitor. Several hundred formats can be easily managed in the data memory. During the actual capping process, the machine monitors the speed, torque and angular position parameters on each capping spindle.

The Ratilight Puck bottle transfer system

The Ratilight Puck bottle transfer system forms the core of a line. From bottle placement to final capping, the system guarantees Safe standing and gentle transport of the containers. The injection moulded transport moulds all have the same external dimensions. The only difference is the internal contour.

Besides Standard pucks for bottles up to 1,000 millilitres and High-speed lines for bottles up to 500 millilitres customised and format-dependent Ratimilled pucks complete the range. Several bottle formats can be processed with Ratilight standard pucks. This results in a high level of process reliability in a complete line. Formats can be changed quickly and cost-effectively, minimising format part costs.

If closed bottles are to be demoulded automatically, i.e. removed from the machine, the Demoulding machine 1200 further. It works with a large adjustment range and adjustable tilt angle. As a stand-alone device, it is equipped with its own control unit.

More information on http://www.rationator.de