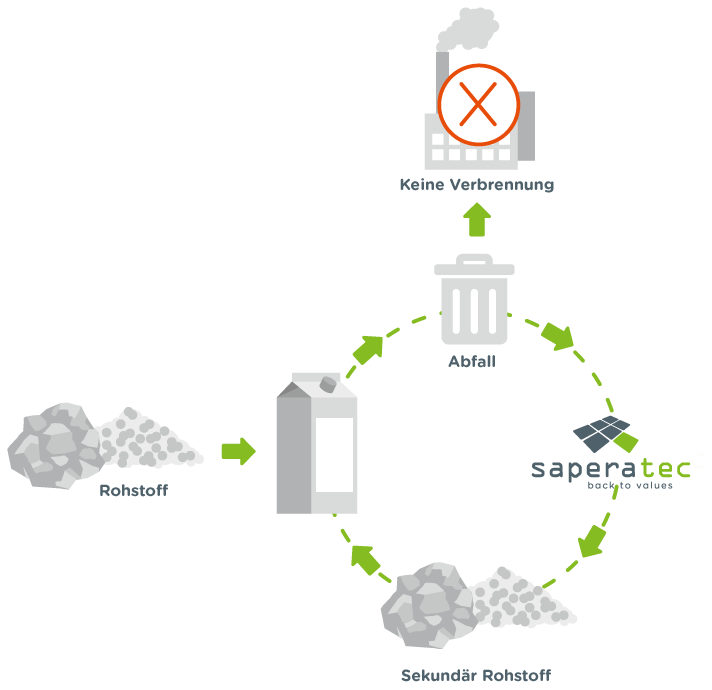

In order to keep important raw materials from composite packaging waste and beverage cartons in the cycle, Saperatec is supported by mechanical recycling technologies from GEA. This allows multi-layer composite materials to be treated in the separation process.

The recycling process is used at the new Saperatec site in Dessau-Roßlau in Saxony-Anhalt. There, from up to 18,000 tonnes of packaging waste processed and treated annually in 2023. These include multilayer composite materials made of plastic, aluminium and paper.

GEA developed the process of separation and washing in partnership with Saperatec in the company's own Separation Test Centre in Oelde. The aim was to underpin the project with facts and figures and to demonstrate the Evaluate processes for sedimentation centrifuge technology. The laboratory-scale tests thus became pilot tests that served as a process guarantee for the defined production scale with a GEA dryMaster CF decanter and a directly driven TSI 200 disc separator.

To the Delamination and for dissolving into the respective components Saperatec a separating liquid. The different layers are separated from each other and sorted by material in further process steps. The separated plastic (e.g. polyethylene) is then processed into regranulate using established processes. The company passes the separated aluminium foil on to aluminium producers and refiners for reuse.

Disc separators for raw material recovery

A disc separator from GEA was also used. The separators are available with different drive types: gear drive, belt drive, direct drive and integrated direct drive. The integrated direct drive provides the Latest development stage in the separator development process is a motorbike. It works without a motor shaft, gearbox, belt, coupling and motor bearings. The small number of installed components reduces energy losses and maintenance costs and increases the availability of the machine.

The disc separators with integrated direct drive can be operated flexibly. The bowl speed is infinitely variable within a certain range via a frequency converter. In addition, maintenance itself can be significantly simplified.

Source: GEA

More news about Connected

Women in Packaging: Committed entrepreneur with team spirit

Smart packaging from conception to recycling

KHS relies on Plasmax barrier technology

Reusable containers for continuous material flows