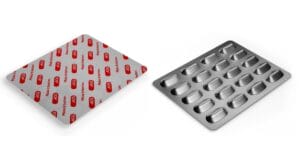

Companies in the pharmaceutical sector are increasingly focussing on the sustainability of their packaging. With PharmaGuard, Südpack Medica is launching a recyclable blister concept on the market in which the top and bottom film are based on PP.

The substitution of a less environmentally friendly packaging concept with a recyclable alternative is a building block for companies in the pharmaceutical, medical goods and life science industries in terms of improving their eco-balance.

„Currently, the legal situation does not yet oblige the pharmaceutical industry to comply with recycling quotas. However, those who switch to recyclable packaging concepts now are investing in their image and giving themselves a good head start in the market.“

Michael Hermann, Head of Research & Development at Südpack Medica

The PharmaGuard blister concept for solids applications is the company's latest innovation. The top and bottom films, which are produced using a unique co-extrusion process, are based on PP and are harmonised in terms of their sealing performance. This not only ensures pack quality, but also safety in an efficient process.

Thanks to its processing window, the bottom film shows good thermoforming performance and demoulding behaviour. In addition, Südpack customers also benefit from the processing of PP films, despite the typical material characteristics, because the Materials can be processed on existing packaging lines with only minor modifications. become.

For product protection and the best possible stability, the Equip material structures with different barriers depending on the product to be packaged.

„As a raw material base, PP naturally offers an excellent water vapour barrier. Thanks to our co-extrusion process, however, the material can also be equipped with a barrier against oxygen and UV rays.“

Michael Hermann

Compared to the PP-based blister film solutions currently available on the market, Südpack's solution also scores highly in terms of transparency, allowing a clear view of the product.

A life cycle analysis carried out by Sphera proves that the packaging concept is more efficient than the blister solutions commonly used on the market. reduced climate impact (in CO2-eq.) and lower energy and water consumption has.

Source: Südpack Medica

More news on pharmaceutical packaging

Alltub takes over La Metallurgica

Limburger Packaging Group integrates Müller & Bauer

Sharp invests massively in expanding packaging capacities

ACG launches sustainable blister solution on the market