In agriculture, one thing is required above all else: the best possible quality at competitive prices. In order to fulfil this, the process chain from harvesting to storage and further processing through to retail must function smoothly. Schoeller Allibert offers a wide range of containers and transport options for fruit and vegetables.

Among other things, this requires packaging solutions that ensure that the goods are undamaged, fresh and fast reach their destination. The containers and crates in which sensitive goods such as fruit and vegetables are stored and transported are exposed to environmental influences such as heat or moisture. These factors can cause their contents to rot prematurely.

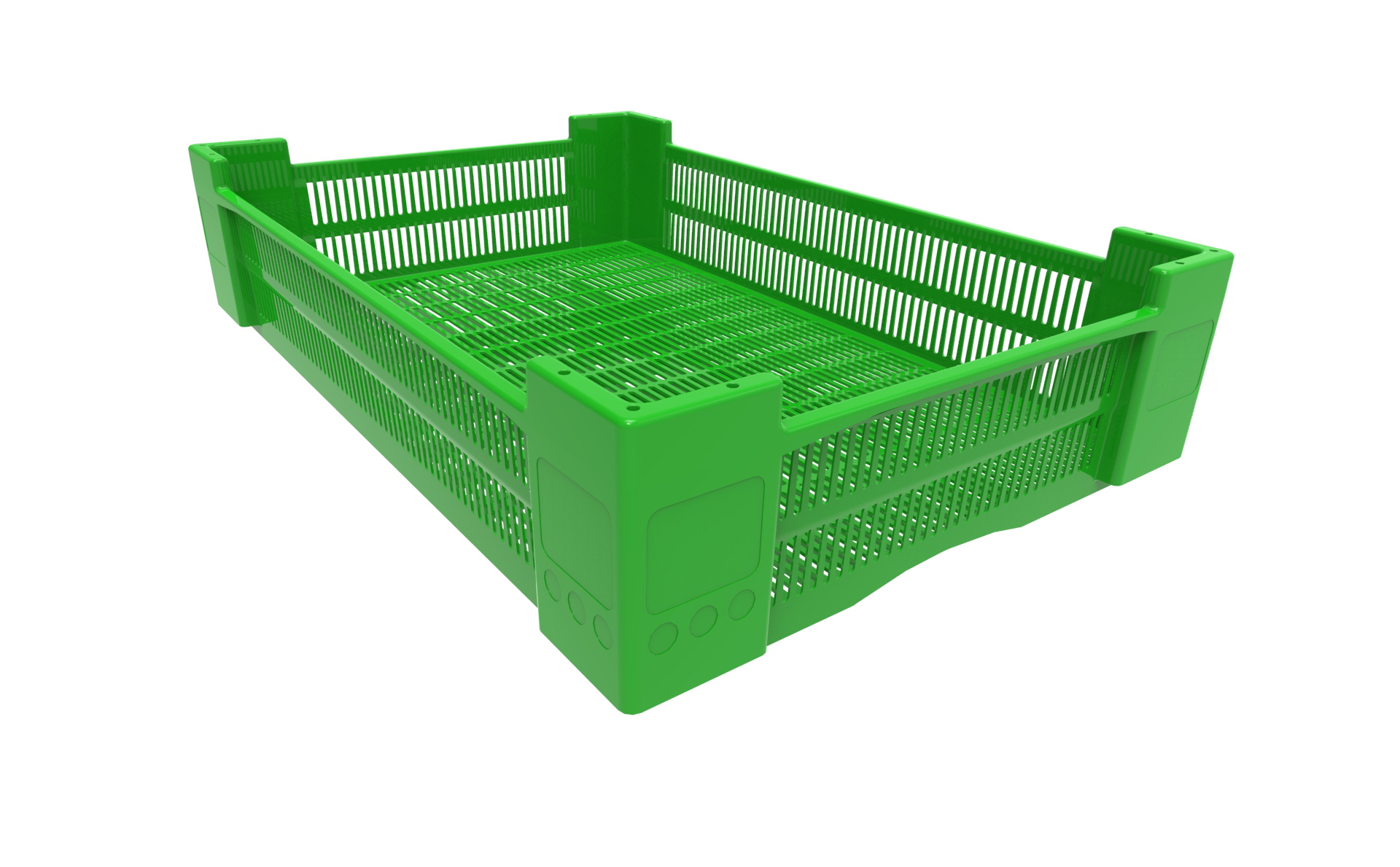

The remedy here is the Reusable containers from the specialist for plastic packaging solutions Schoeller Allibert. Made from polypropylene (PP) or polyethylene (PE), they are robust, shatterproof, offer good air circulation and protect the sensitive contents from transport damage and rotting. In addition, they are always the same size and weight, regardless of environmental influences. Their service life is up to ten years if handled properly, even under adverse weather conditions. This makes it easier for farmers to handle their goods, saves storage space because the containers are particularly easy to stack and fulfils the strict hygiene regulations of the food industry.

Handling heavy loads

One of these transport and storage containers is the Big Box MaxiLog. The large load carrier is comparatively light, robust and can hold a stacking load of up to 4,500 kilograms. It also has smooth and straight inner walls. This makes the Big Box very easy to clean. The perforated version of the Big Box is particularly suitable for storing and transporting fruit and vegetables.

It ensures excellent ventilation in the entire cargo area and thus improves the shelf life of the goods, especially on longer transport routes. Frozen fruit can also be stored very well in the closed version. Another plus point: the large capacity of 610 litres and a load capacity of 450 kilograms. To protect against moisture, all horizontal outer surfaces are bevelled to facilitate the drainage of water.

Another large load carrier that is also ideal for fruit harvesting and the subsequent transport of the fruit. Storage and transport of field-fresh goods is the Big Box Maximus. With their bulges in the base, the containers can hold more fruit than comparable load carriers in this class. The Big Box is lightweight and has a large internal volume. The basic dimensions are 1,200 x 1,100 millimetres and 1,200 x 1,200 millimetres.

Gentle on sensitive berries

Transporting berries can be tricky. If they are not stacked optimally, they can easily become bruised and start to rot. Schoeller Allibert has developed a Special containers for soft fruit developed for the safe storage and freezing of goods.

The berry container has a capacity of twelve kilograms and is designed so that the berries can be stored and transported particularly gently. An ingenious ventilation design speeds up the freezing process and ensures optimum product quality.

The container is designed for temperatures down to minus 40 degrees Celsius. It is also easy to handle and stack. Double-walled pillars ensure high stability and load-bearing capacity. Up to 18 crates can be stacked on top of each other.

Save space during return transport

To save space when transporting empty crates, farmers, logistics companies and fruit wholesalers can rely on the Folding steps from Schoeller Allibert. With foldable containers such as those in the Prelog and Ortus series, the user saves up to 80 per cent space compared to rigid solutions.

This significantly reduces the cost of return transport. With their straight walls and rounded corners and edges, they are ideal for transporting fruit or vegetables.

Hygiene pallet H1

Not only containers that come into direct contact with the goods, but also pallets must fulfil strict requirements in terms of quality and cleanliness in food production and processing. Schoeller Allibert has developed the H1 for this purpose.

It is characterised by its special design and high cleanliness standards, is stable, durable and easy to handle. The ventilation system ensures continuous cooling, even when several pallets are stacked on top of each other. A circumferential, seven millimetre high stacking edge prevents the goods from slipping during transport. Empty pallets can also be safely stored on top of each other.

[infotext icon]The company also has numerous solutions in its programme for other applications such as grape harvesting, asparagus or lettuce harvesting, with which the sensitive goods can be transported and stored particularly gently and efficiently[/infotext].