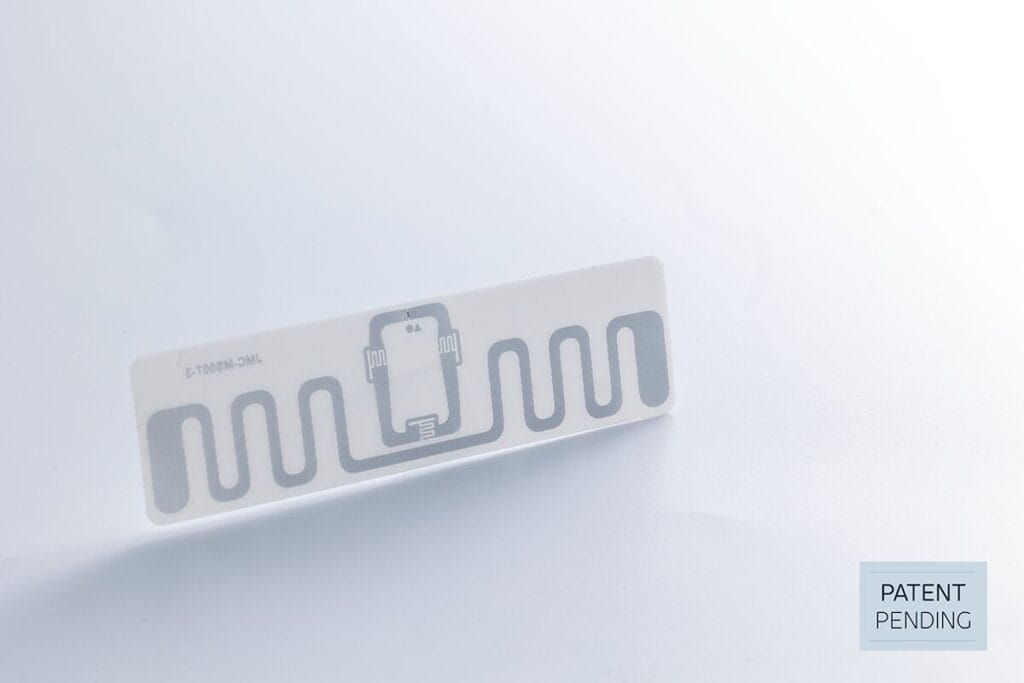

Checkpoint Systems has introduced a new RFID inlay for reusable food packaging. The so-called Chinook inlay is microwave-resistant, can be used multiple times and is designed to combine sustainability and traceability in the food sector.

With the Chinook Inlay, Checkpoint Systems is launching a new solution for use in reusable food packaging. The RFID tag was developed specifically for packaging that needs to be both microwaveable and durable - for example in system catering, food retail and the catering sector. The inlay is designed to improve traceability along the supply chain while also helping to minimise waste.

According to the manufacturer, the inlay remains fully functional even after 45 microwave cycles - with stable RFID performance. An independent test by the European EPC Competence Centre (EECC) confirms the reliability: the transponder is particularly suitable for applications with frequent microwave exposure without any significant loss of readability.

Traceability meets circular economy

Checkpoint Systems emphasises the importance of inlays in the context of increasing regulatory requirements for packaging. From 2030, only packaging that is recyclable or reusable is to be put into circulation in the EU. Disposable plastic packaging will then no longer be permitted for certain applications.

The Chinook inlay is tailored to these requirements. It consists largely of reusable materials, is compliant for indirect food contact and can be used in various forms of packaging - such as plastic or glass containers, according to the company. It can be used for fresh and frozen food as well as pre-cooked food.

An additional sustainability benefit: thanks to its robust design, the inlay can be used in several life cycles. This not only reduces packaging waste, but also facilitates stock control and logistics - for example through real-time tracking and automated inventory.

Areas of application in the food sector

The possible applications are diverse: in food retail, the Chinook Inlay helps to efficiently manage the circulation of reusable packaging - especially for products that are processed or packaged directly on site. In restaurants and canteens, the solution enables transparent tracking of packaging in the reusable system. And in production facilities with high hygiene standards, the integration of RFID technology can help to digitalise processes and make them more sustainable at the same time.

Checkpoint Systems sees the introduction of the new inlay as an important step towards combining digital traceability and ecological packaging solutions. According to the company, it is working with partners from retail, logistics and food production to integrate the inlay into existing reusable systems.