Tobacco company JTI Switzerland has tested a new adhesive application system from Robatech on a packaging line. The results were surprising: instead of the expected 30 per cent, the tests showed a 48 per cent reduction in power consumption compared to the previous system.

The international tobacco group Japan Tobacco International (JTI), headquartered in Geneva, produces 47 million cigarettes a day at its Dagmersellen site for brands such as Camel and Winston. This corresponds to around 4,600 shipping cartons, which are sent to over 22 countries. On six packaging lines, 50 cigarette sticks are packed into each transport carton in two-shift operation. JTI uses melters, heated hoses and application heads from another manufacturer to glue the bottom and top carton lids. In order to save energy, the tobacco company decided to test a new adhesive application system from Robatech. The new system should save more than 30 per cent energy when melting, conveying and applying hot melt adhesive, promises Martin Berli, Area Sales Manager at Robatech Switzerland.

For JTI Switzerland, the question arose as to whether a small unit such as the adhesive application system could actually conceal an energy-saving potential of 30 per cent or more. „In purely physical terms, it takes around 0.1 kWh to melt one kilogramme of adhesive granulate,“ explains Adrian Vonesch, Head of Maintenance & Repair at JTI Switzerland. „That's always the same amount of energy. The savings must therefore be achieved through the design of the melter, the heated hose and the application head."

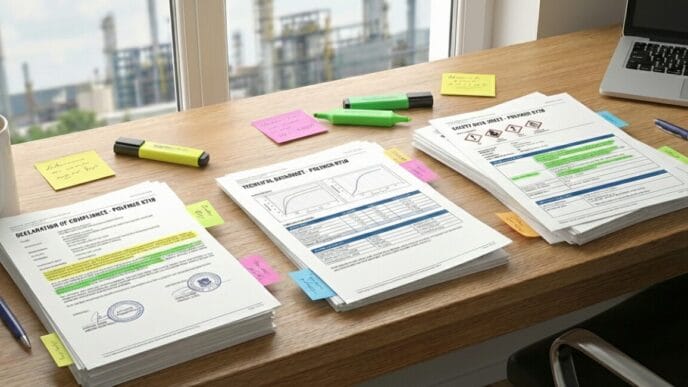

On the test bench at JTI Switzerland

A separate electricity meter was installed on the test line for the test. For fourteen days, JTI employees logged the current adhesive and energy consumption of the existing application system in the horizontal cartoner. Robatech then utilised a one-day maintenance window and installed the free test system: a Vision S melter, two Performa heated hoses and two AX Diamond spray heads for bead application. The new order system goes into operation on the same day. Logging continues for another two weeks.

„The old system remained installed in parallel standby mode. That was a kind of life insurance for JTI. However, I knew that the risk of production downtime was low. Our adhesive application systems have an availability of over 99 per cent. JTI Switzerland has already had three Robatech systems for pallet stabilisation in operation since September 2021. They are running smoothly.“

Martin Berli, Area Sales Manager of Robatech Switzerland

„We had expected an energy saving of 33 per cent, because we know that Robatech is careful with figures,“ summarises Adrian Vonesch from JTI. „The fact that we measured 48 per cent less power consumption at the end of the test compared to the other manufacturer's system surprised everyone.“ For Robatech, it is clear that vision and performa bring more energy efficiency to industrial adhesive application. „Our development team was able to significantly reduce the heat radiation from the melting tank and heating hose using innovative insulation techniques,“ says Martin Berli. „Performa is no longer as hot on the outside as other hoses, which you really can't touch for long. In addition, Performa is fully insulated at the connection points and we optimise the hose length to suit the conditions on site. This reduces unnecessary heat loss.“

High system availability

When developing the new system components, Robatech also focussed on simplifying maintenance and operation. In Dagmersellen, six mechanics and six electricians maintain the warehouse logistics, tobacco processing and production systems. „That's a lot of work that is spread over a few people,“ explains the Head of Maintenance & Repair. „We rely on the devices having a high level of availability and repairs being carried out quickly. Robatech is just a phone call away. That makes the company attractive for us.“

The young employees in particular find the Vision melter modern and attractive. Adrian Vonesch: „The employees enjoy working with the appliance. The arrangement of the maintenance-relevant parts is well thought out and the functions are clear. We didn't even need any training, just a short briefing."

Since the field test for gluing the cartons 24 per cent less hot-melt adhesive is also required on the former test line. „It's just a question of the optimum setting parameters. Our service team knows them and can set them for every adhesive application system,“ says Martin Berli from Robatech. In any case, the customer is satisfied with the energy savings. The test result shows that even small units such as the adhesive application system can harbour great savings potential.