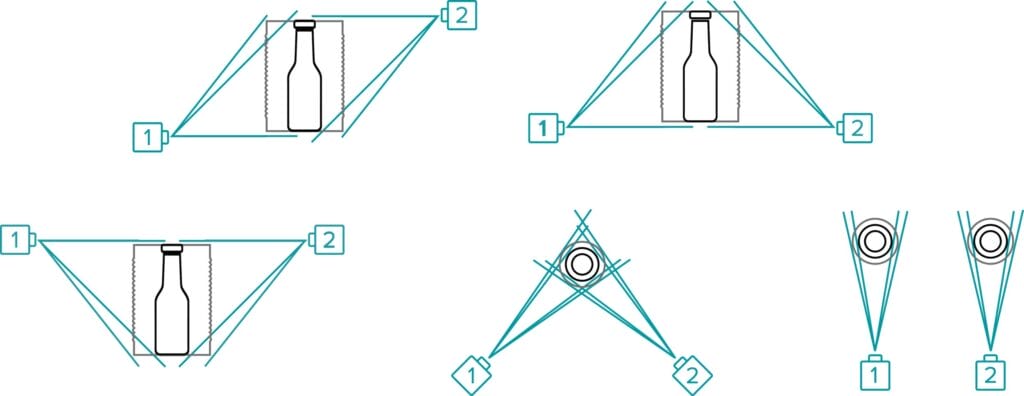

The reliability of an X-ray inspection depends primarily on the selected camera positions. The more leeway a system offers here, the more precise the foreign object detection can be. The Dual View X-ray scanner enables the full inspection of products in upright containers in various orientations.

For the packaging of food standing products are used regularly, whose special properties make it difficult to check the contents. Glass jars and cans in particular are typical types of packaging. X-ray inspection systems have therefore long been part of the basic equipment in many production facilities. In most cases, however, a simple top-down system is not sufficient to reliably detect the product; the limitations of such solutions are quickly reached. Blind areas are too often created by blind spots, jeopardise care and safety. That is why Wipotec on two flexible X-ray detectors throughout.

The high flexibility of the Dual View SC-S 5020 X-ray scanner in the arrangement of the X-ray sources and detectors optimises foreign body inspection to a maximum compared to conventional dual-beam systems. Two detectors can be aligned at different heights and positions, so that the entire product area is covered. The possible arrangements include both cameras parallel to the base or lid, combinations of these as well as irradiation at 45° and 90° angles.

Adjustment is made by means of an integrated servo drive. Versatile Product heights are therefore no problem, as well as complex liquid or solid fillings. At the same time, software optimised for inspection divides each inspected product into several individual segments. No foreign body remains undetected.

The compact and hygienic design of this inspection system fully fulfils the following requirements the special requirements of the food industry. The X-ray system reliably achieves outstanding inspection results at high throughput rates of up to 1,200 items/min - with the lowest false reject rates.

Source: Wipotec