The Rotzinger Group is presenting its expanded packaging and process portfolio for the first time at interpack. Highlights include the Paloma feeding system, the FLK/VRM filling and sealing machine, the TLT blister machine in a new compact design and a production line for bars.

The Paloma infeed system picks and places products in cartons, boxes, thermoformed packs, flow-wrapping machines and cartoners. With the help of camera-controlled high-speed delta robots, the machine identifies products on the conveyor belt and places them accordingly in the infeed of the subsequent process. The system processes both unpackaged and packaged products and, thanks to its modular design, enables the direct integration of a packaging machine infeed chain (horizontal or vertical) into the cell and its loading with aligned products. The system is ideal for applications in the food and confectionery industry and can be used in numerous areas, such as for baked goods or fresh products - in combination with a new integrated buffer system, it also offers new, efficient layout options.

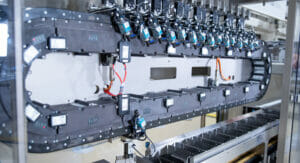

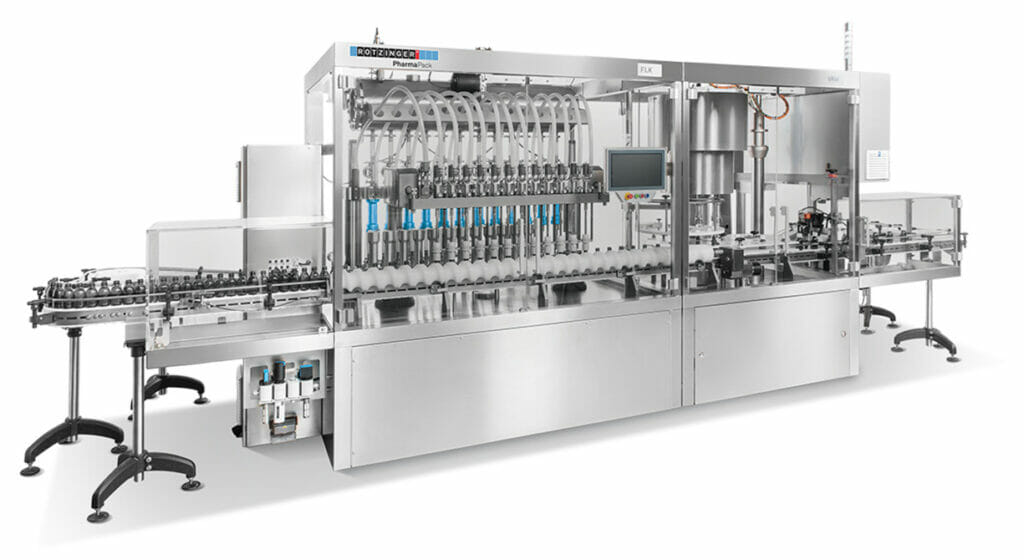

Maximum flexibility when filling and closing

When it comes to filling pharmaceutical and cosmetic products, the FLK/VRM filling and capping machine plays a central role. The machine combines the advantages of a linear filling machine and a rotary capping machine, thus offering maximum flexibility and efficiency. The volumetric and mass flow filling system can fill various products, from aqueous to viscous and sticky liquids, and can be easily adapted to different formats.

Blister machine with new compact design

Rotzinger also presents a new and improved version of its TLT blister machine, which processes up to 400 blisters per minute.. The TLT has been redesigned and is characterised by its flexibility, safety and short changeover times combined with high overall system efficiency.

The machine is for the primary packaging of pharmaceutical products can be used flexibly and can be connected to several cartoning machines. Customers benefit from the modular design for simple and easy retrofitting. To ensure compliance with regulations and to protect the product and packaging material, the production and drive areas of the TLT are clearly separated from each other and can even be completely encapsulated as an option. The machine is ideal for packaging a wide range of pharmaceutical products such as tablets, capsules and coated tablets in conventional thermoforming and aluminium foil.

Flexibility in the production of bars

Bar manufacturers can increase their production output with a solution for the entire process from processing to secondary packaging maximise - all from a single source. The innovative WRL Flex slitting machine from Hansella, which has been part of the ROTZINGER Group since 2021, will be on display. The WRL Flex slicing machine has an adjustable blade position. This allows the product width to be adjusted with minimal effort and without changing components. In addition to greater flexibility, this also reduces production costs and contributes to a faster return on investment (ROI).

Digital Factory Software Suite increases efficiency and quality

Visitors to the trade fair stand at interpack can also see the company's digital solutions for themselves. The Digital Factory Software Suite, for example, promises to increase the efficiency and quality of processes while ensuring end-to-end data access. Paperless production is made possible by fully digitalised Q-checks and a management cockpit, which together ensure continuous improvement on the shop floor. Rotzinger also offers system integration services that support companies with the gradual introduction of the software.

Source: Rotzinger

Rotzinger at the interpack 2023: Hall 1, Stand C07

Rotzinger - More news

Rotzinger presents expanded packaging and process portfolio

Digital solutions for pharmaceutical production

Faller Packaging and Rotzinger together at Pharmapack

Faller Packaging and Rotzinger develop Eco Save Pack