Sometimes companies dare to take unusual paths. Machine manufacturer Rovema, for example, is foregoing an interpack appearance this year, but is inviting customers to demonstrations and presentations at its own plant in Fernwald, Hesse. And they are more than willing to accept the invitation.

Full house in Fernwald. The mechanical engineering company Rovema invited customers and interested parties to its headquarters near Giessen for three consecutive days - from 21 to 23 March - to kick off the „Customised Experience“ series. In 2023, the company will be organising multi-day events in several stages, in which packaging solutions for various areas of the food industry are presented in cooperation with long-standing partners. The topic of coffee packaging took centre stage in March.

And many of those invited turned up. „We are very pleased with this kick-off event, because travelling to Fernwald is not a matter of course. In the end, we had visitors from all over Europe, which makes us very proud and shows us that our event is relevant,“ says CEO Christoph Gusenleitner, who has headed the company since April 2022. And the journey was definitely worth it. On site, visitors were treated to several live demonstrations with commentary on the Rovema BVC 260, which was specially prepared for packaging ground and whole bean coffee. An option with a degassing valve was demonstrated for bean coffee and a high-performance application for portion packs, so-called frac packs, for ground coffee.

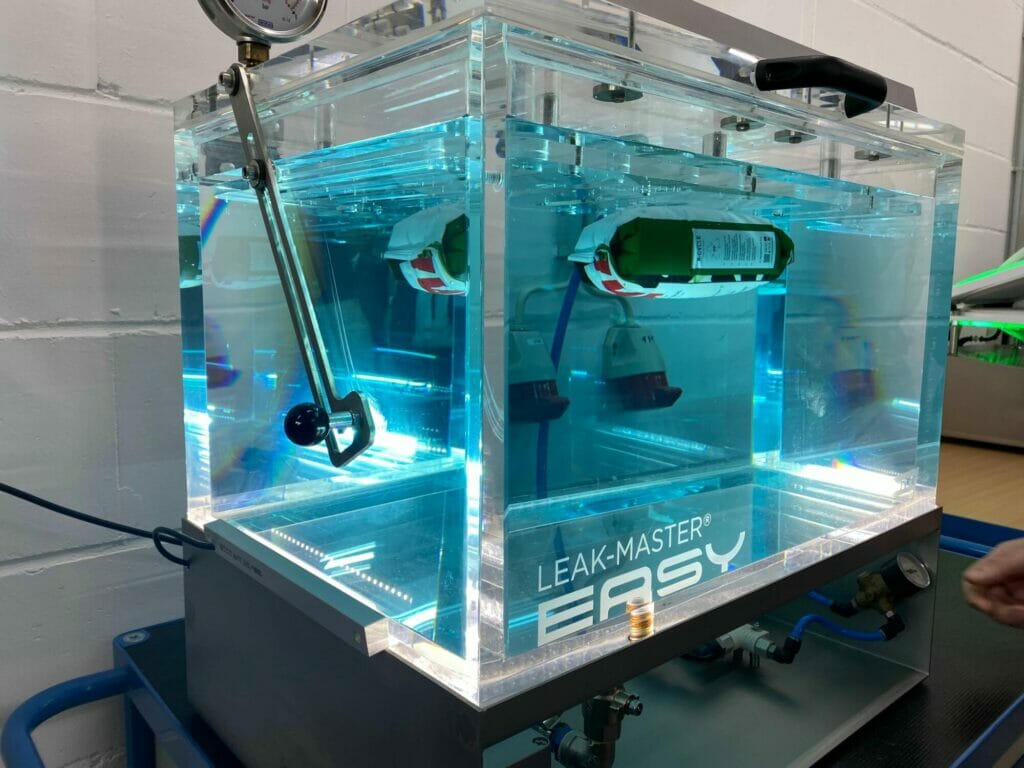

The demonstrations included packaging materials from the cooperation partners South pack and A. Hatzopoulos for use. Even before the films were formed into bags on the shoulder, they were ultrasonically fitted with the Wicovalve one-way pressure relief valve from the Swiss cooperation partner Wipf which, together with the packaging, also withstood the subsequent sealing test in a water bath. Equipped with the innovative valve applicator for button valves the BVC 260 achieves an output of up to 70 bags per minute when loaded with such mono-PP packaging materials.

Meeting new requirements

Michel Schlaepfer, Key Account Manager at Wipf, explained exactly how the valve works to the attentive guests in a short presentation. In contrast to comparable designs, the Swiss company does not rely on a mechanical valve, but instead uses an oil barrier to ensure pressure equalisation on one side. The valve is necessary because the coffee still releases gases in the packaging, which would otherwise cause the packaging to swell or even burst open. The company currently offers the valves in the combinations PE+PET or PP+PET. In future, however, there are plans to include more recyclable versions in the portfolio, such as a mono-PE solution. „The sealing technology must also fulfil new requirements,“ says Schlaepfer.

Like Wipf, the two other co-operation partners also presented the advantages of their packaging materials in shorter presentations. Antonis Proedrou emphasised the recyclability of A. Hatzopoulos' mono-PP and mono-PE solutions out. The X-Cycle range has already won various prizes, including the WorldStar Award, and is also certified by the Cyclos-http Institute and Interseroh, among others. Isabell Lauer from Südpack in turn emphasised the Sustainability benefits of mono-Pe and mono-PP films of the company. By converting to the monofilms, companies could save up to 19 per cent of material and thus up to 58 per cent of CO2 save. Sustainability also applies to printing: SPQ technology enables the same quality to be achieved with less ink. The Ochsenhausen-based company already won the German Packaging Award in Gold in 2021.

Exchange and expertise take centre stage

However, a major plus point of the event format became apparent between the presentations and demonstrations: the exchange and networking. Over - how could it be otherwise - delicious coffee from the local barista, the representatives of well-known coffee producers and the packaging experts came together to discuss the latest developments in coffee production. Numerous exciting discussions and we talked shop.

So does the format represent a valid alternative to a trade fair presence? Ingo Hamel, CTO at Rovema, didn't want to put it quite so bluntly. However, some of the advantages are obvious to him. „Here on site, we can present ourselves as a company in a completely different way than at a trade fair, where it is sometimes difficult to show what the company can do. Here, on the other hand, customers get an insight into our production and can answer the question ‚Is Rovema suitable for my product‘ much better for themselves.“

During a guided tour of the Rovema plant, which has grown impressively over the years, the visitors were then able to get a detailed picture of the machine manufacturing process. The centrepiece here is the workshop, where every shoulder that is later installed is shaped by hand in great detail. The specialists at the plant also presented a complete filling line, from filling the beans to packing them in cardboard containers. You don't get to see something like this every day.

In short, both Rovema and its cooperation partners, as well as the visitors who attended, were highly satisfied with the start of the event series. The next block has already been scheduled. In May, everything in Fernwald revolves around sweets and snacks.

http://www.rovema.com

http://www.hatzopoulos.de

http://www.suedpack.de

http://www.wipf.ch

More news on the subject of packaging technology

Designed for complex logistics requirements

Multivac expands portfolio with new labelling series

Connect motorised rollers digitally

Sustainability as a driver of innovation in cosmetics packaging