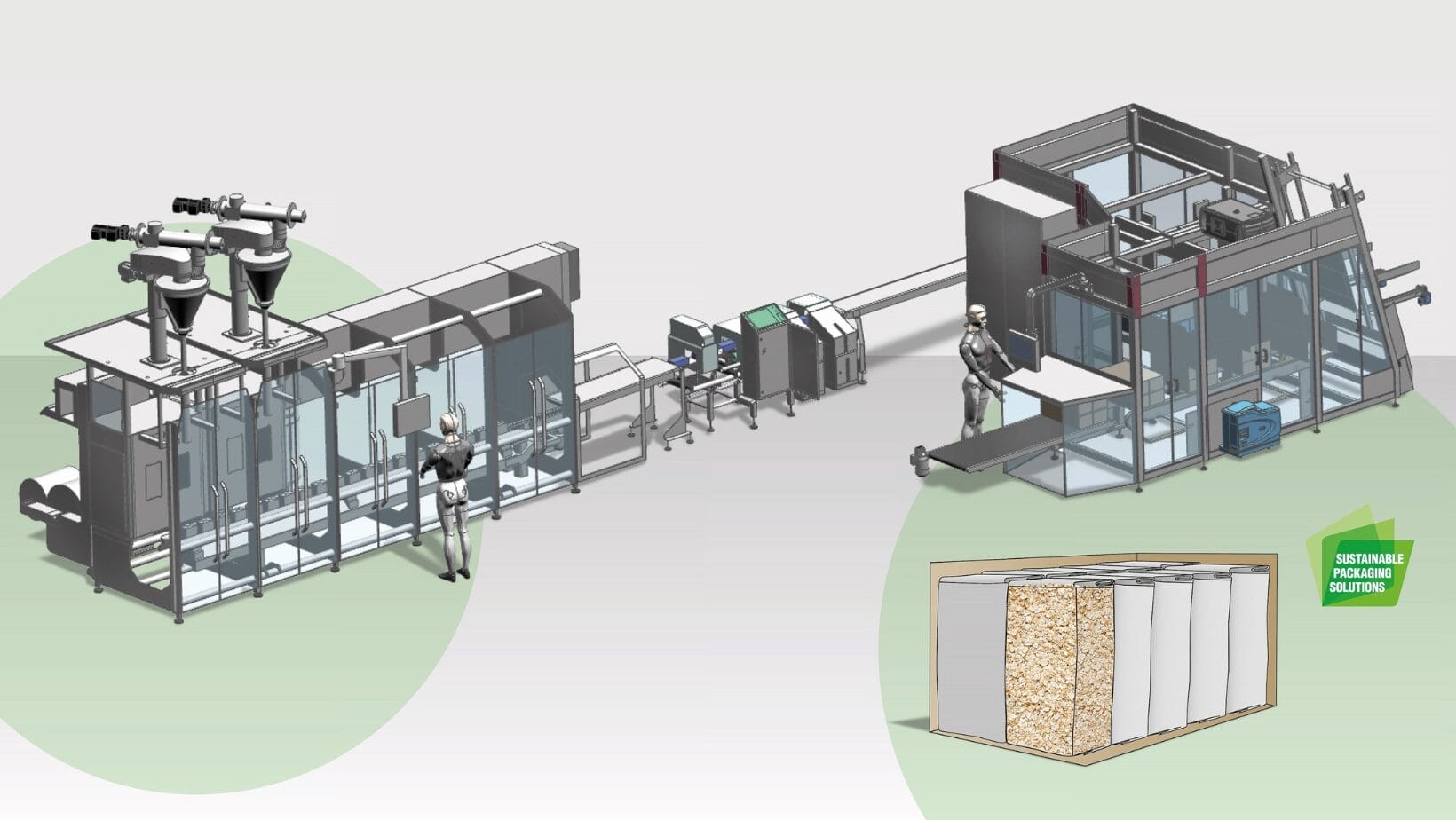

At Hispack 2024, Rovema will be presenting an integrated, compact packaging line with an output of up to 100 pouches per minute. The turnkey system was specially developed for the transport-optimised packaging of powders, granulates and flakes and offers maximum flexibility in the smallest of spaces.

The upstream block packaging machine SBS Twin is characterised by its continuous operation and its versatility in bag design. The machine is a Modular combination of two flow-wrapping machines and downstream systems for bag head and bag closure design. Equipped with two filling tubes, the SBS 250 Twin enables a wide range of bag shapes and closures, including 90° fold-over of the bag flap, label and tape closures as well as hot melt and tin-tie closures. The machine is suitable for filling and sealing a wide range of food and non-food products, including cereals, pasta, spices and biscuits.

The new packaging line promises efficient and precise packaging of one kilogramme of maize flour with an output of up to 100 bags and ten WA cartons per minute. The machine has a special dosing system that enables the compression of powders This ensures particularly transport-optimised and low-dust packaging. The high fill level in the bags and transport boxes maximises the use of packaging space.

Particularly noteworthy is the integration of an additional module into the upstream SBS block packaging machine, which Processing of sustainable packaging materials in the future. Rovema has line expertise that makes it possible to combine individual packaging machines and install synchronised and automated packaging lines - all from a single source.

„With complex packaging lines, the precise coordination of primary and secondary packaging, a well thought-out overall layout and an optimised material flow with the best possible accessibility are crucial. This calls for experts who can offer the user the greatest possible benefit and minimise investment risks.“

Ingo Hamel, CTO at Rovema

Rovema's packaging line is in line with the increasing demands for sustainability and automation in the food and packaging industry. With the aim of, to be able to react flexibly to packaging material developments and recycling specifications and to offer customers maximum future security and machine availability, Rovema relies on the company's many years of automation expertise.

Source: Rovema