The fresh food counter is the centrepiece of every butcher's shop and supermarket. However, buying behaviour and the shortage of skilled workers demand new solutions. Instore pre-packing can be one answer to this. S.A.M. Kuchler Electronics has specifically developed a compact and automated slicing and packaging solution that has the potential to change the industry.

Supermarkets and butchers are facing a key challenge: staff shortages are forcing many businesses to restrict opening hours or close their counters. At the same time, customers expect high-quality, fresh cold cuts without long waiting times. After all, goods from the counter are a key differentiator between supermarkets and discount stores. Instore-PrePacking enables the fully automated slicing and packaging of sausage and cheese products directly in the store or butcher's shop. This allows products to be prepared hygienically and efficiently for the service counter.

Slicing and packaging machine specialist S.A.M. Kuchler specialises in modern counter solutions. The roots of the Austrian family business go back to Fritz Kuchler, who developed the world's first automatic slicing machine in 1962, revolutionising the food industry. More than 60 years ago, he wanted to emphasise automation in the company name: S.A.M. stands for sine (without) auxilio (arduous and labour-intensive help) manus (of the hand). Today, the company is run by Valentina and Constantin Kuchler in the second generation. They are continuing the tradition of innovation. With numerous patented technologies S.A.M. Kuchler Electronics stands for the development of efficient and innovative solutions for butchers, supermarkets and the food industry.

Special attention is paid to the company's high level of vertical integration. All machines are developed and produced at the site in Klagenfurt, Austria - from the milling shop to the turning shop, in-house electronics production and the assembly of all mechanical and electronic components. The company also has its own development company on site.

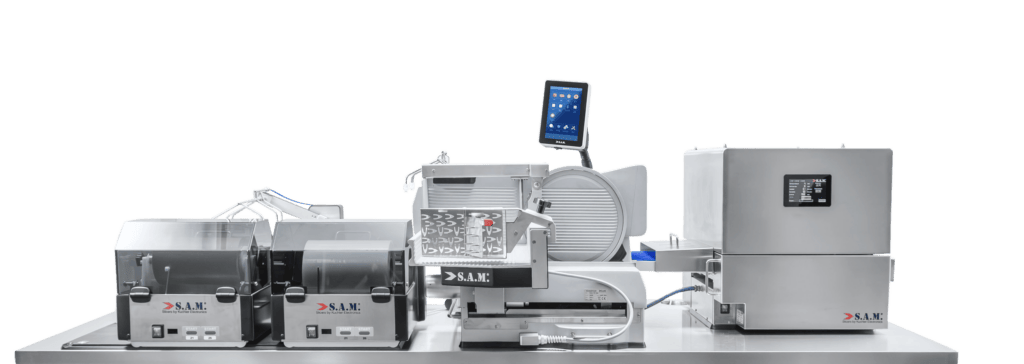

Most recently, a new machine was created: the PX3 MAP. It was developed to a space-saving, cost-efficient and automated solution for cutting and packaging to offer. This machine is revolutionising the market by seamlessly integrating these processes, which not only reduces the workload of personnel but also ensures the high quality of the products.

Freshly cut in the market

The entire process, from cutting to finished packaging, is fully automated. This saves time and guarantees a consistent result of the highest quality. The modified atmosphere keeps the sliced meat fresh for much longer than in conventional packaging. In addition the machine also offers the option of offering vacuum-packed products, which makes them even more versatile.

The PX3 cuts up to 150 packs per hour and packs them automatically. This packaging solution reduces losses and increases efficiency. And it also scores highly in terms of flexibility: the machine can easily switch between different products, cutting patterns, vacuum packaging or gas flushing within a very short space of time. This means that products can be produced quickly and in line with demand and a varied range can be offered every day.

Compared to industrial slicer systems, which are designed for mass production and are associated with high investment costs, the PX3 MAP works very effectively even with small quantities. And unlike large production systems, the compact all-in-one solution only requires a footprint of two metres and fits on any counter.

Multilayer packaging: an invention from Kuchler

The machines from S.A.M. Kuchler Electronics realise different packaging concepts, all based on proven multilayer packaging technology. Different variants are used depending on the machine type and area of application: The PX3 produces classic SamPaks. These are multi-layer sliced meat packaging that does not require gas or vacuum. The cold cuts are automatically sliced and hygienically packaged directly on the counter. Each layer can be opened individually, keeping the products fresh for longer. The transparent packaging ensures that quality and freshness are visible at first glance.

The PX3 MAP complements this concept with additional technologies and produces MapPaks (with modified atmosphere) and VacPaks (vacuum-packed). These variants offer a longer shelf life.

A particular highlight is the BioSamPak: a transparent, multi-layer packaging made from compostable cellulose, developed for fresh, moist products such as sausage and cheese. This innovation was designed in-house. S.A.M. Kuchler holds a Europe-wide patent for it, as it is the first transparent delicatessen packaging made from wood fibres that can also be used for moist foods.

Possible applications for different types of business

The PX3 MAP impresses with its versatility and can be used flexibly. It not only produces modified atmosphere packaging, but can also offer vacuum-packed products. This makes it ideal for a wide range of requirements:

- The machine can be used directly in the store on the counter or in an adjoining room to produce freshly packaged cold cuts for the service counter every day.

- Thanks to modified atmosphere packaging, craft businesses can deliver their goods to supermarkets or vending machines in the highest quality and with an extended shelf life.

- A high-quality range of cold cuts can be prepared centrally by supermarket chains for various shops and supplied with a uniform appearance.

In addition to process optimisation, the PX3 MAP also offers economic benefits. Counters can remain open. The investment pays for itself quickly thanks to the reduced personnel deployment, while the longer shelf life of the products helps to minimise sales losses. In addition multi-layer packaging helps to avoid food waste. The customer only removes the portion required and the rest remains hygienically sealed until it is consumed. This means that no opened packs dry out.

Supermarkets and butchers focus on innovation

„We think about technology from the perspective of the trade. Because those who know the practice develop differently. Our solutions have to fulfil three requirements at the same time: They should appeal to customers, make work easier for machine operators and be profitable for business people,“ summarises Valentina Kuchler, Managing Director of S.A.M. Kuchler Electronics.

A successful example of the use of the PX3 MAP is the Ruckdeschel butcher's shop in Wunsiedel. The company was looking for a way to optimise its efficiently and durably pack the products produced in the traditional butcher's shop, without compromising on freshness and flavour.

„We have recognised that pre-packed goods are the key to the food retail sector. Thanks to our collaboration with S.A.M, we were able to tap into this area and now supply several Tante M shops. We are planning to open our own hybrid shop, which will be open around the clock and stocked with pre-packed goods.“

Martin Krasser, Master butcher and managing director.

The compact design of the machine is very important for the specialists. It cuts exactly the right number of pieces, relieves the strain on staff and significantly increases efficiency. Around 1,000 packs are currently produced there every week.

Edeka Hayunga also relies on the PX3 MAP at all of its locations in addition to the S.A.M. PX3 machines, which slice and pack fresh in the store. The machine is used centrally to produce high-quality raw ham packs with a longer shelf life.

For businesses that want to prepare for the challenges of the coming years, in-store pre-packing is not just a trend: it is the future of modern and customer-friendly food processing at the fresh food counter.