The Italian packaging converter Sacchital is expanding its production capacities and opening a new flexographic printing department in Pregnana. The centrepiece of the investment is a Vision CI printing machine from Bobst, with which the company intends to strengthen its technological portfolio and its market position in the flexible paper packaging sector.

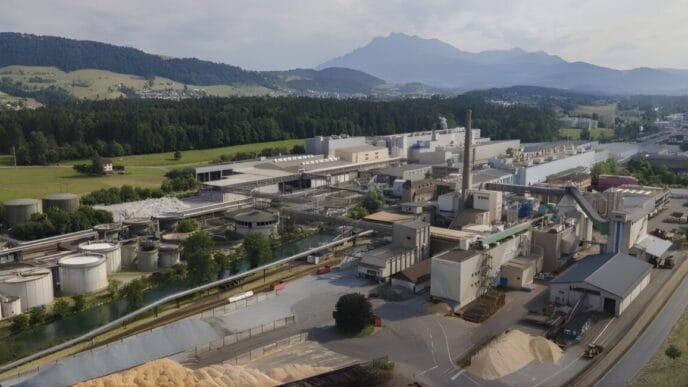

Sacchital, an established converter of paper-based flexible packaging for decades, is expanding its site in Pregnana with a new flexographic printing hall covering an area of around 2,200 square metres. The new department is part of a strategic growth programme and will provide space for up to four flexographic printing presses and complementary technologies in the long term.

Expansion of flexo expertise as a strategic step

At the centre of the new production hall is a Vision CI printing machine from Bobst. According to the company, the project was developed by Sacchital's management team together with Bobst Italia. The aim is to expand the flexographic printing range in a targeted manner and to be able to serve different market requirements more efficiently. Alberto Palaveri, Executive Member of the Group Board of Sacchital, explains that the new site is an essential part of the growth strategy and should help the company to respond more quickly and cost-effectively to an increasingly fragmented market.

Sacchital continues to focus on a technology-neutral approach. The company is investing in gravure, flexographic and digital printing solutions in parallel in order to be able to offer customers suitable production processes depending on the application and print run structure. The new flexo infrastructure complements this strategy and increases production flexibility.

Focus on speed, versatility and sustainability

According to Bobst, the Vision CI responds in particular to the increasing demands for speed and versatility in the packaging industry. The machine is designed for different substrates and run lengths and is intended to reduce material and ink consumption through automated processes, short set-up times and high repeat accuracy. According to Sacchital, this is a prerequisite for continuing to serve existing core markets such as baked goods and at the same time opening up new segments such as pharmaceuticals, household and personal care products.

Another focus is on the transition from plastic to paper-based packaging solutions. Palaveri emphasises that Sacchital is actively supporting brand owners in this transformation and sees this as an important area for the future.

Long-term collaboration and technological development

Sacchital and Bobst have been working together for many years, including on material tests and technological developments. Bobst points out that the new system should not only improve print quality, but also increase overall productivity at the site. The smartGPS automatic register system plays a central role in this, as it significantly reduces set-up times and waste, according to the manufacturer.

In addition, the Vision CI is designed for both solvent-based and water-based colours. Sacchital therefore believes it is well equipped for future regulatory and market requirements. As soon as the framework conditions allow, the company intends to increase the use of water-based colours.

Source: Bobst