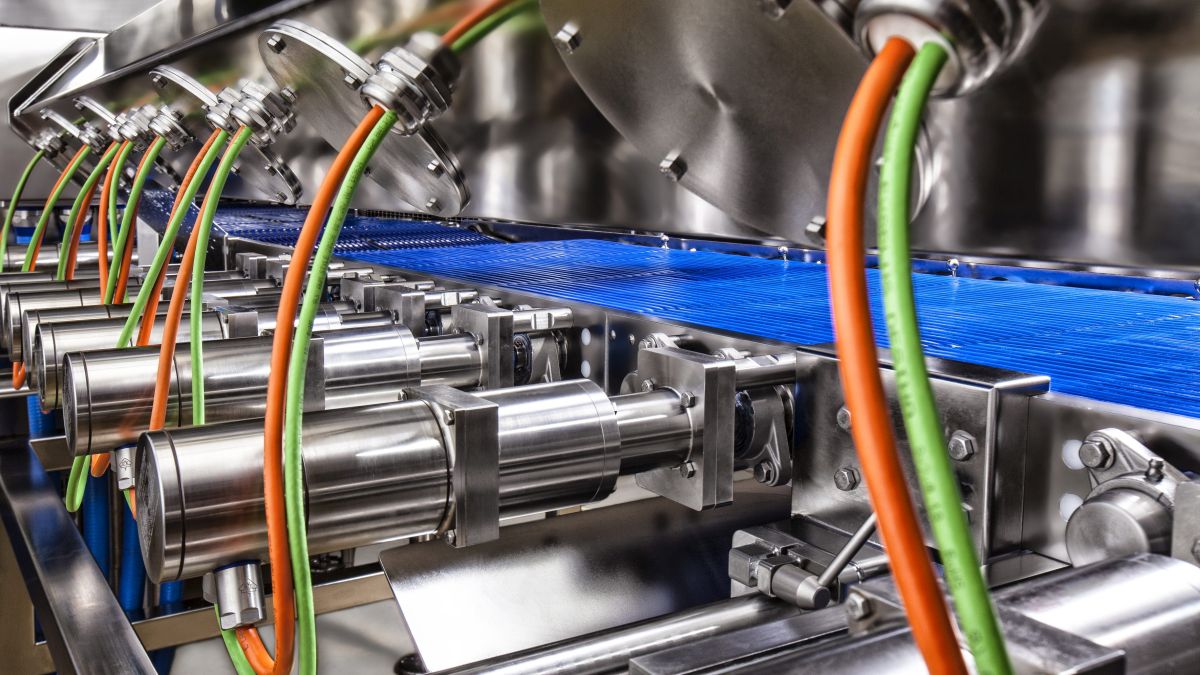

Dipl.-Ing. Schindler & Wagner GmbH & Co KG from Plüderhausen has developed a modular slicing machine for processing sausage and cheese products. Thanks to its "walk-in design", it is intended to speed up and simplify the time-consuming cleaning and changeover work on slicing machines for sausage and dairy products.

Schindler & Wagner touts various advantages of its product: The blade can be easily and safely installed and removed while standing, so that production can be resumed quickly. The High-tech slicer-checkweigher machine combination ensures particularly hygienic production conditions. All potential lubrication points are located outside the cutting and weighing area. Contamination of the product is therefore ruled out, as the company emphasises. This design has a positive effect on the Best before date (MHD) from.

Up to 6,000 knife cuts per minute

The knife in a Cutting application for sausage products works at a speed of up to 6,000 cuts per minute, depending on the product. It must be resharpened regularly and cleaned when the product is changed. Schindler & Wagner has worked intensively on the good Accessibility of the blades for maintenance purposes The knife is installed or removed by simply opening the safety frame and sliding the upper runner, which holds the product, to the side," explains Sebastian Siegle, technical operations manager at Schindler & Wagner. An employee can then enter the slicer and install or remove the cutting tool.

"The knife is basically the centrepiece of our cutting system."

Sebastian SiegleTechnical Operations Manager of Dipl.-Ing. Schindler & Wagner GmbH & Co KG

In addition, the specialist for customised slicing systems has ensured that the knives are lighter and can be handled by a single employee. The design engineers have made various modifications to the knives. Drill holes to avoid imbalances. The welcome side effect of this measure was a 40 per cent reduction in the weight of the components. A few years ago, Schindler & Wagner put its own blade production facility into operation to manufacture the blades.

Special focus on knife production

A few years ago, Schindler & Wagner set up its own production facility to manufacture the knives. Knife production This is where the knife is milled, pre-ground and finally coated with a non-stick coating. "The blade is essentially the centrepiece of our cutting system," explains Siegle. "The manufacturing process and the robust choice of material together ensure a precise cut with low axial run-out and exact on-weight production."

Schindler & Wagner at the IFFA 2019: Hall 11.1, Stand A31