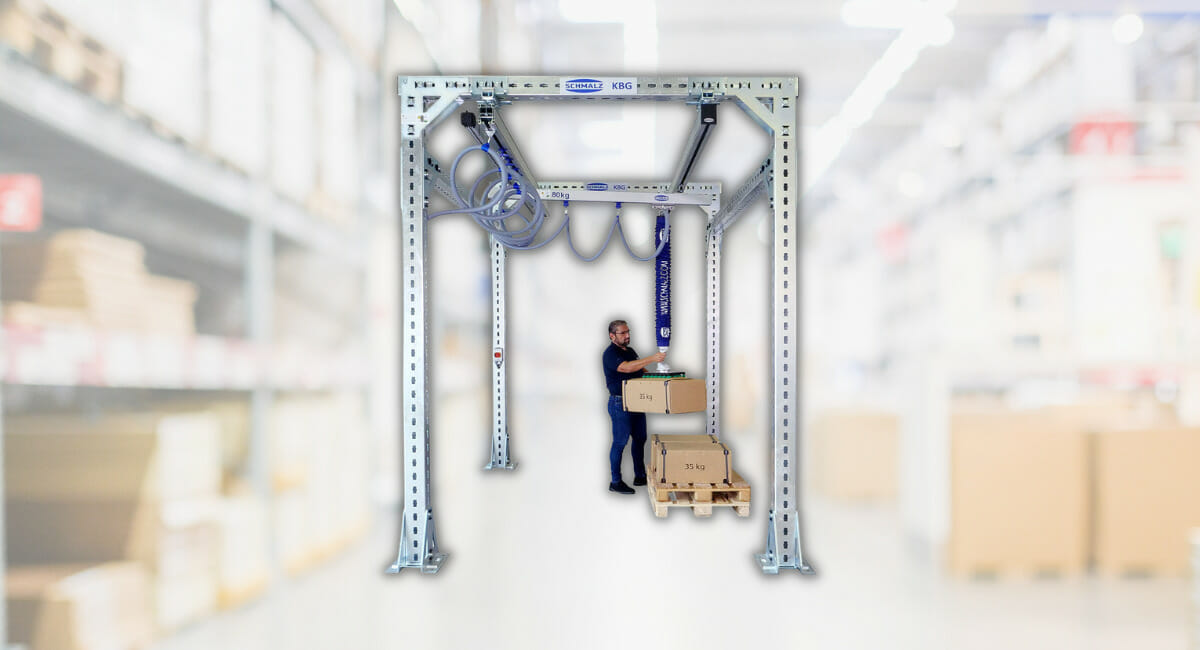

In order to transport heavy parcels from A to B in the factory, you sometimes need the help of a suspension crane. However, not every environment allows for conventional ceiling mounting. Schmalz has now designed a modular support system for this purpose.

As the name suggests, a suspension crane system is mounted on a superstructure. From now on, this no longer has to be an existing building structure. With the KBG crane gantry, J. Schmalz GmbH has designed a modular support system for its SRA aluminium suspension crane system and thus opens up even more application possibilities for customised crane solutions.

Flexibility and availability at short notice were two of the requirements when developing the KBG. The company therefore also utilises the modular concept here, which in this case is based on just twelve components. The special feature: All friction-locked connections are made using a special screw set. This simplifies assembly and eliminates errors. In addition, Schmalz only uses one profile size for the entire crane gantry, which is supplied directly with the corresponding holes for the screw fittings. A crane gantry consists of at least two gates and can be extended as required - even at a later date if the production, assembly and logistics layout changes.

The maximum load capacity is 500 kilograms. And that the subsequently installed system also holds what Lard promises, Independent strength calculation of all load-bearing components using the finite element method. The entire system is designed in accordance with DIN EN 13001 and achieves stiffness class HC3 and S class S3.

Source: J. Schmalz GmbH