Vacuum expert Schmalz will be showcasing its latest intralogistics solutions at LogiMAT 2025. The focus will be on grippers and lifting aids that support skilled workers and robots in picking and moving.

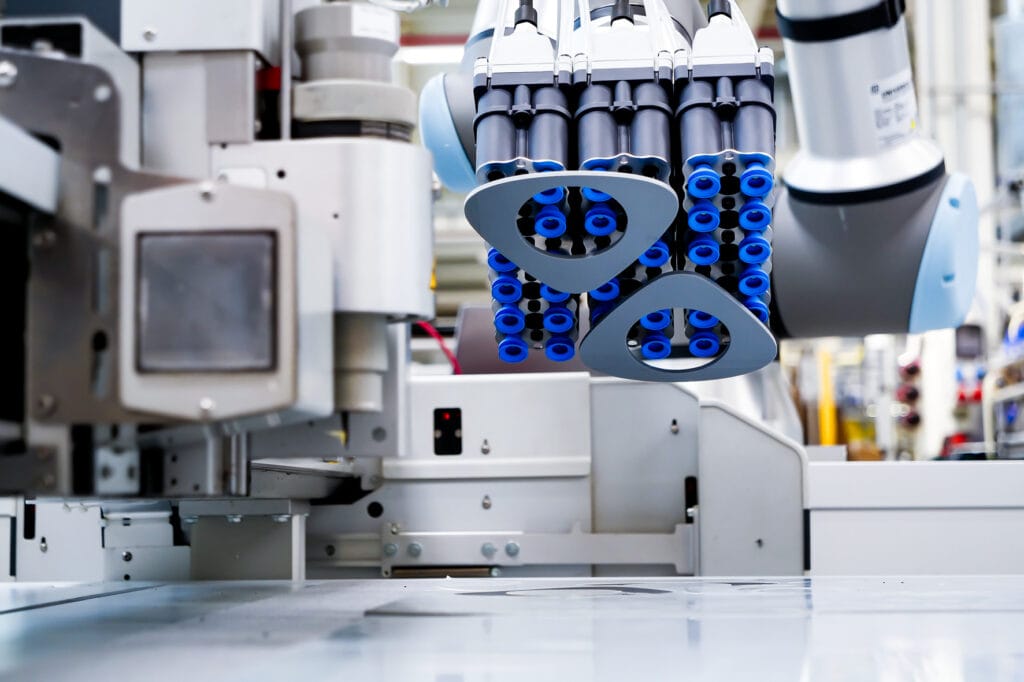

The FMG matrix area gripper has a compact and modular design. It is suitable for gripping flat and predominantly suction-tight workpieces in various shapes and dimensions. It can also Complete product layers and very thin components safely and securely. This allows users to easily automate high-mix, low-volume processes, for example in pick-and-place applications. Additional modules can be added if required.

The The FQE-V gripper was developed for handling workpieces in automation technology. has designed. The modular, freely scalable system can be used to safely handle workpieces of different sizes and shapes. Thanks to smart design tools, users benefit from particularly fast project planning of grippers in batch size 1.

The mGrip finger gripper in hygienic design fulfils the highest purity standards. Thanks to its flexibility and adaptability, it can pick up delicate objects such as baked goods precisely and gently. It is ideal for in automated packaging processes, for picking small parts into nets or bags, for example. The SBPG bin picker will also be on show at the stand. This helper for autonomous bin picking enables components to be removed from bins, thus optimising the material flow in production.

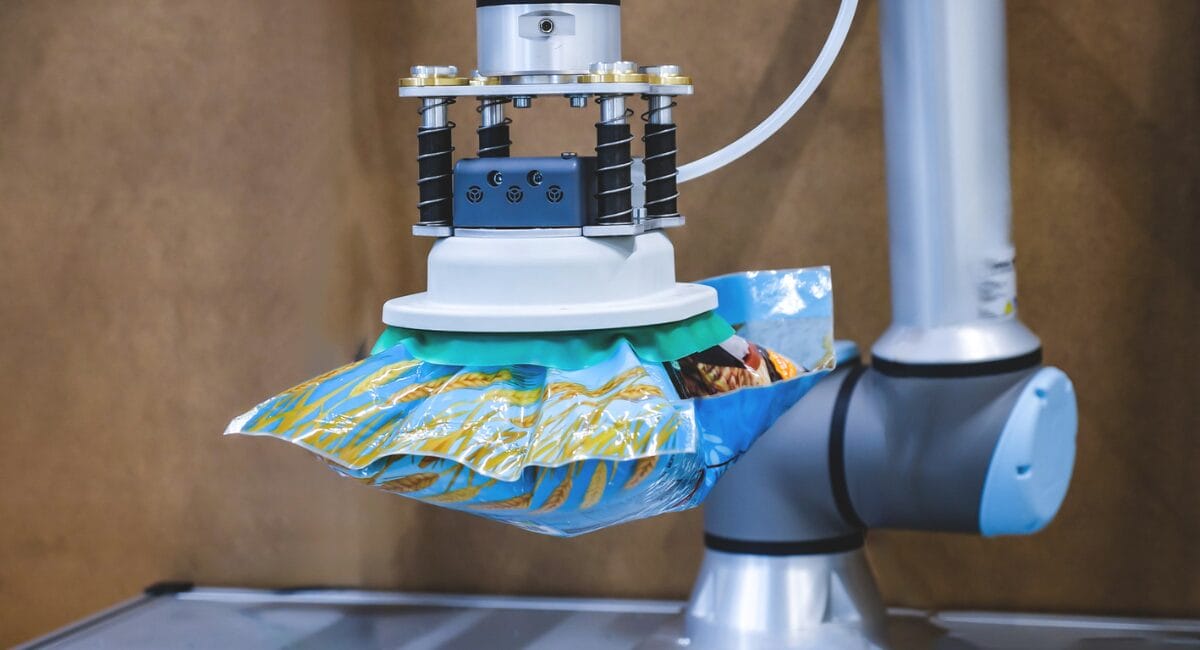

The PSSG bag gripper is a strong lightweight with a special feature: the robust sealing lip guarantees a very long service life. Schmalz has developed it especially for handling sacks, it moves heavy loads safely and efficiently. The combination of vacuum technology and an intelligent gripping mechanism makes the PSSG an ideal solution for logistics centres and production facilities.

The JumboFlex has been the first choice when it comes to this for many years, Move workpieces weighing up to 50 kilograms. Schmalz proves that there is always room for improvement with the redesign of the vacuum tube lifter. It is now even more intuitive to use and more ergonomically designed - the handle fits perfectly in every hand. Its flexible handling ensures optimum use in modern production.

Source: Lard