Vacuum expert Schmalz will be presenting handling solutions for bags, cardboard boxes and other packaging at LogiMAT. The grippers and ergonomic lifting aids support skilled workers and robots in all picking and transfer tasks.

From 19 to 21 March, experts in warehousing, material flow, transport and robotics will meet at the LogiMAT international trade fair for intralogistics solutions and process management in Stuttgart to find out about new technologies. Vacuum expert Schmalz will be presenting several product highlights. The New PSSG sack suction pads for handling paper, plastic and fabric sacks. It also accommodates other porous and bag-like workpieces. The lightweight housing made of glass fibre-reinforced plastic closes with a sealing element made of FDA-compliant silicone or wear-resistant NBR. The PSSG can therefore be used in many industries. In addition to automated processes, it also demonstrates its strengths in manual handling on the JumboFlex tube lifter. A filter fleece protects the system from contamination, while the adjustable support grid prevents bag packaging from being pulled in too tightly, which could damage the workpiece.

For the JumboFlex the Schmalz Application Assistant (SAA) digitalisation tool is available. The tool records the hose lifter's operating data and informs users, for example, about the degree of contamination of the filter. This allows them to plan maintenance in advance.

Schmalz presents the FSGC bellows suction pad for handling workpieces with different contours. The round gripper with 4.5 folds lifts packaged goods in logistics centres and supports the transfer of cardboard boxes, shipping bags, paper and plastic bags. Thanks to the flexible sealing lip and the increased stroke it adapts very well to structured surfaces. The FMG matrix large-area gripper is also included. Schmalz has worked on it Seven modules, each with twelve suction cups, blocked together to form a flexible surface. The 84 suction points can be controlled individually. This allows the FMG to automatically pick up workpieces with varying geometries.

Automatic picking of dissimilar workpieces

Schmalz speeds up order picking with the ivOS Pick and Pack Solution Kit. The specific solution package was developed for integrators and machine builders. for setting up bin-picking applications ivOS recognises each workpiece, selects the suitable gripper with the appropriate gripping strategy and picks the load, so to speak. Users configure the system directly via the graphical interface.

Vacuum generator with many options

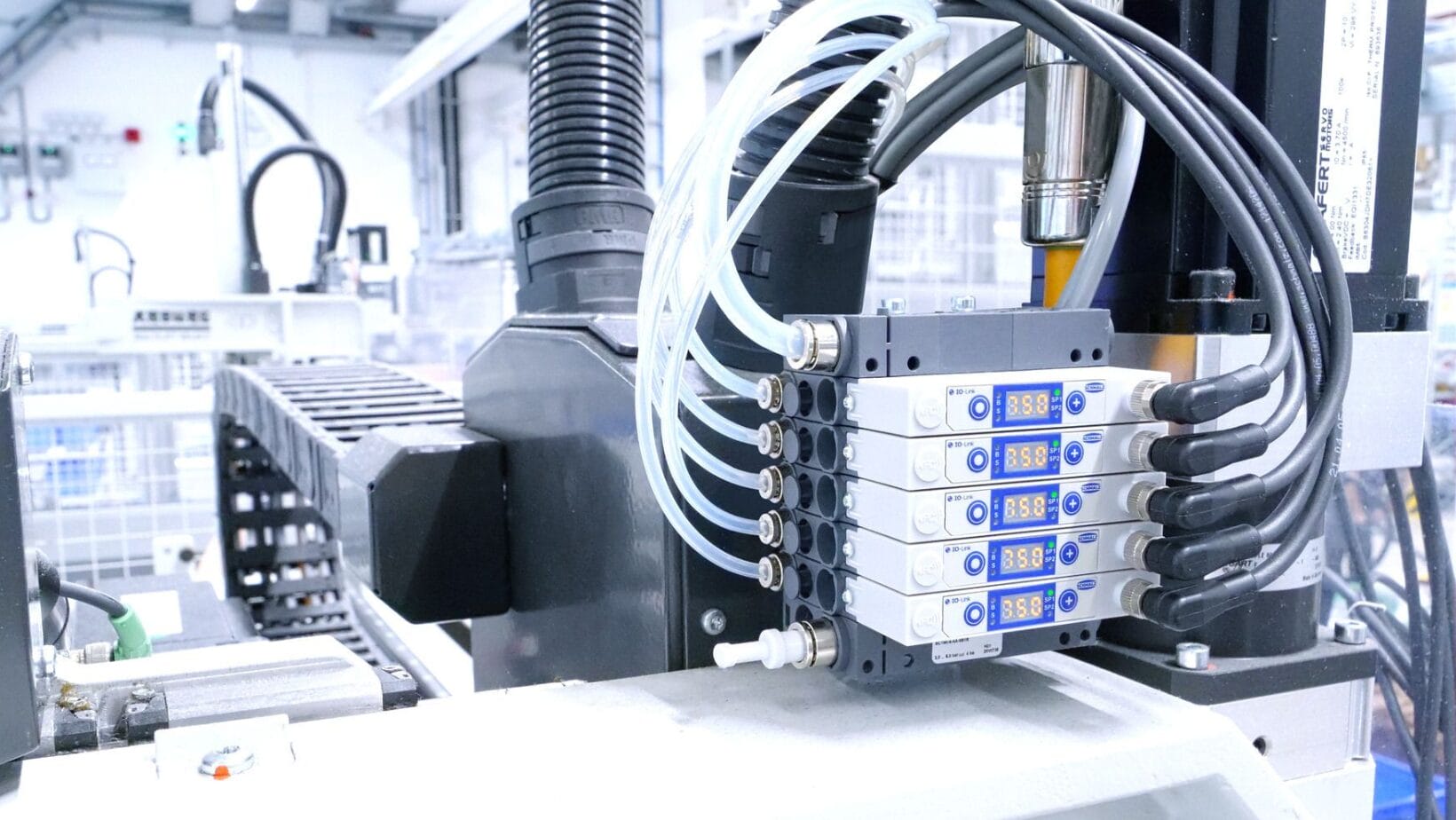

The SCTMi mini compact terminals control up to 16 separate vacuum circuits and are so small and light that they can be mounted directly on the gripper or on a moving axis. They evacuate the gripping system quickly, are very energy-efficient and scalable. This makes them suitable for flexible use in different applications.

The new SCPLb / SCPLc multi-stage compact ejector is ideal for porous workpieces such as cardboard and packaging materials thanks to its high suction capacity. It is particularly efficient with suction-tight materials thanks to its air-saving control. In large vacuum systems with partial loading, the SCPL can compensate for leakage flows and thus keep the vacuum level constant. Thanks to the integrated vacuum monitoring and valve technology, users do not need an external control solution.

Source: Lard

Schmalz at LogiMAT 2024: Hall 7, Stand C05