Schmalz is also thinking outside the box when optimising its vacuum systems: a current research project is focusing on the suction organs of leeches.

Velcro fasteners, the lotus effect and aeroplane wings are some prominent examples of how bionics can solve technical problems. Because Nature offers fascinating answers to everyday challenges. „It is usually very efficient,“ emphasises Dr Harald Kuolt. He heads up the research projects at Schmalz. „We have been looking for natural suction methods to improve our own vacuum systems.“

Schmalz found what he was looking for in leeches. With their two sucking organs at the front and rear ends, they have the ability to cling to different surfaces. Whether slimy or porous, under or above water - thanks to the Combination of suction adhesion and mechanical gripping or clinging, they can attach themselves securely to their hosts. Together with the University of Freiburg, Schmalz started a project to better understand the biological adhesion systems. „We investigated the functional morphology and biomechanics of leeches,“ explains Prof Dr Thomas Speck. He heads the „Botany - Functional Morphology and Bionics“ working group at the University of Freiburg.

After manual pull-off tests, the researchers built rotating systems and determined the centrifugal force at which the flukes detach from the respective surface. „We broke new ground and developed special test set-ups for this purpose, to measure the adhesive forces of the leeches,“ explains Thomas Speck. In a current research project, the team is investigating the anatomy of the sucking organ, which consists of muscle-controlled sucking, sealing and grasping lips.

„Understanding the form-structure-function relationship of the suction organ is essential for further abstraction and implementation steps for new, bionically optimised systems from Schmalz.“

Dr Simon Poppinga, TU Darmstadt

From the aquarium to the industry

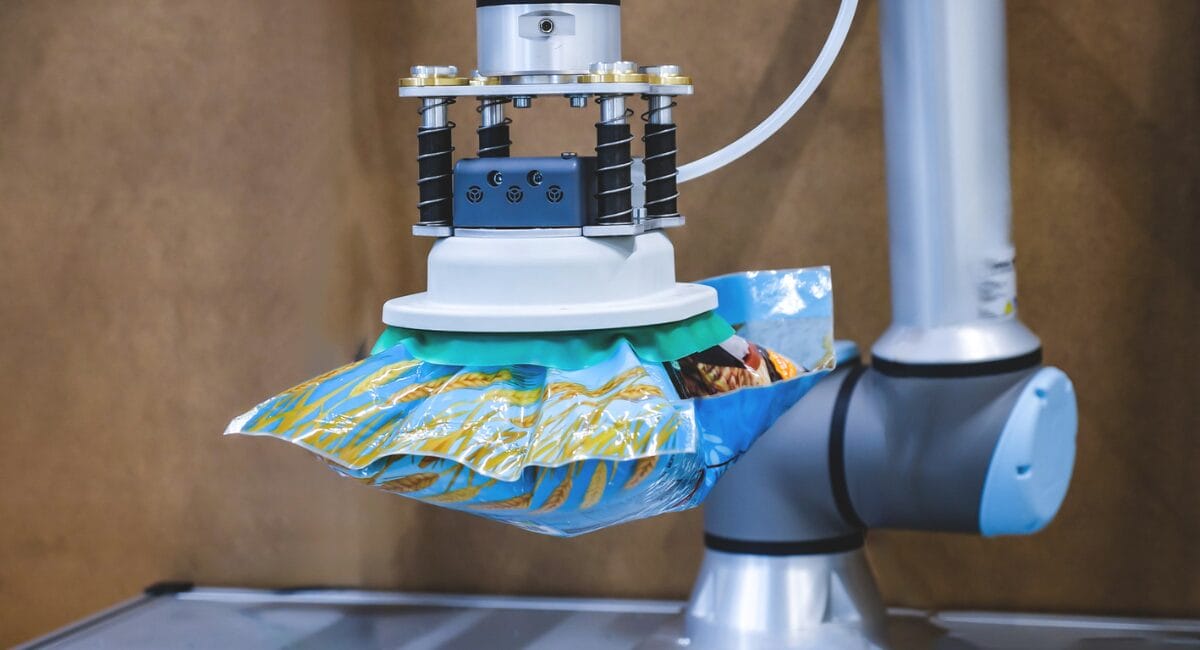

Harald Kuolt: „Our pre-development department then produced a prototype that differs from our standard range.“ Firstly, the sealing lip runs in a different direction to that of standard suction cups. Secondly Schmalz adapted the radii of curvature and combined hard and soft materials.

„We were able to reduce the dead volume and thus evacuate much faster. Our aim is for the new suction cup to perform better than conventional models in terms of holding and shear forces as well as sealing behaviour. It should also be possible to manufacture it industrially and its carbon footprint must be comparable to previous suction cups.“

Dr Harald Kuolt, Head of Research Projects at Schmalz

The focus is currently on two variants that Schmalz is further optimising. The new models save energy thanks to the short evacuation times. They seal better on rough surfaces and impress with their long service life. Thanks to the new structure of the seal, they should also ensure a secure hold on uneven or sensitive surfaces. „The suction cups must function reliably in standard applications; we don't want to develop a solution for a few special cases,“ emphasises Harald Kuolt.

Source: Lard