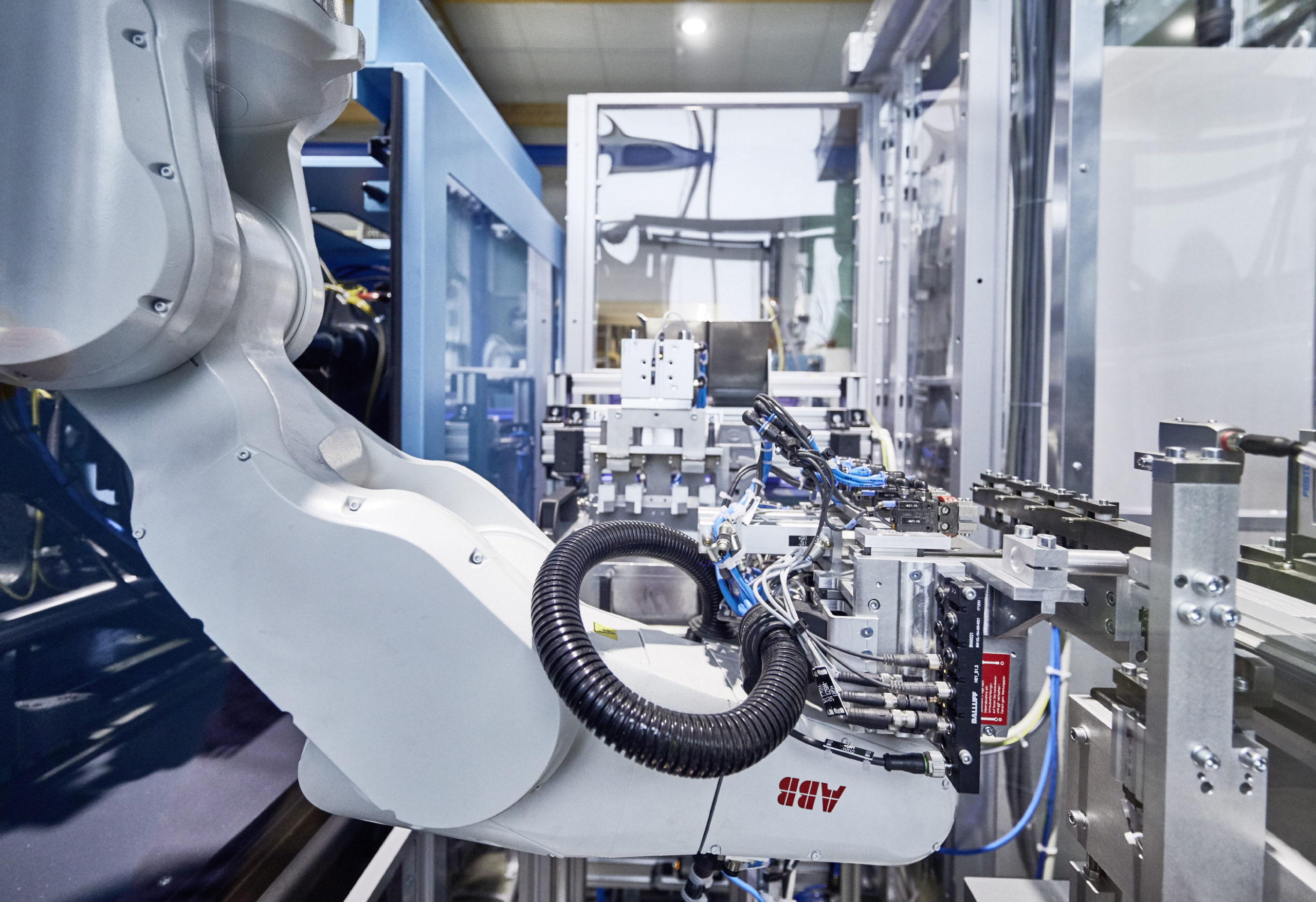

Schneider Kunststofftechnik GmbH has invested 700,000 euros in the expansion and modernisation of production capacities at its company headquarters in Kirchheim in Unterallgäu. Four injection moulding machines were purchased, including two all-electric systems. Schneider Kunststofftechnik now has a total of 17 injection moulding machines. In addition, two fully automated production cells and three articulated robots were added to the machine park.

Overall, the modernisation investments have increased production capacity by a third. „This will enable us to optimally meet the increasing demand from the market now and in the future,“ explains Managing Director Drita Schneider. Above all, the modern Production cells made it possible, now operating in three shifts instead of two to produce. Two of the three Articulated robots produce a total of 15,000 plastic parts for cartridges per day. With the third Robot system 2.5 million keys per year are to be produced on behalf of customers.

The investments also realised the goal of Energy saving pursued. Especially the all-electric injection moulding machines save up to 25 per cent of electricity compared to the hydraulic machines previously used.

Schneider Kunststofftechnik GmbH produces, among other things Technical plastic parts for the packaging industry. The production department employs 19 people, who are now receiving training for the modern machines.