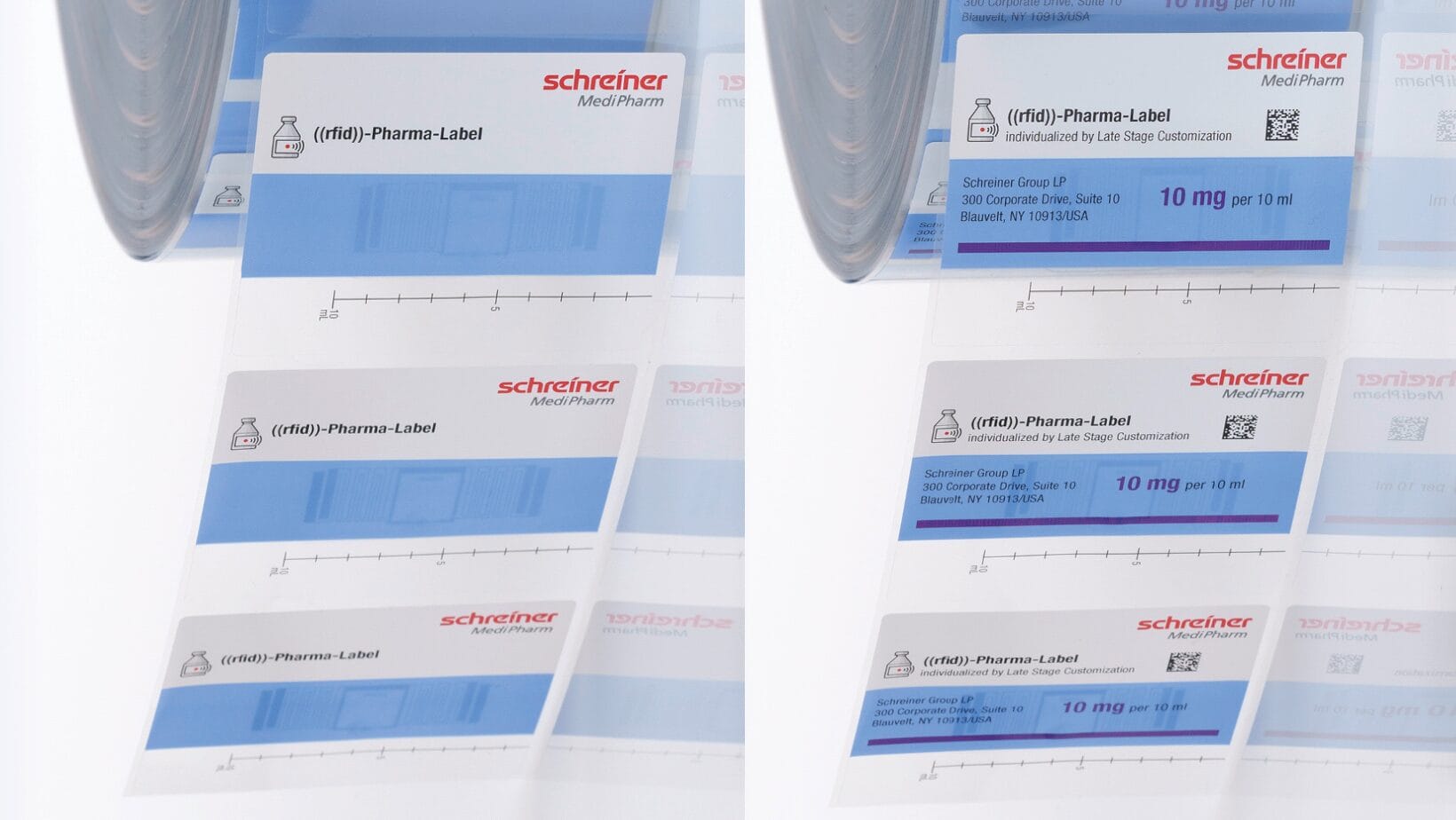

To support pharmaceutical companies in optimising their supply chain, Schreiner MediPharm presents an innovative solution: late stage customisation for RFID labels. This makes it possible to provide smart labels at short notice and programme the integrated RFID chip for specific orders.

Schreiner MediPharm is responding to the challenges of an increasingly fast-changing healthcare industry by expanding its Late Stage Customisation Service to include RFID and NFC labels. Initially, the labels Pre-produced in large quantities with integrated RFID inlay and stored as semi-finished goods. At the customer's request, the prefabricated labels are then customised using digital printing and delivered at short notice. This enables the flexible production of sophisticated smart labels and ensures a rapid response to customer enquiries.

Schreiner MediPharm's special service not only offers a high level of customisation and short lead times, but also ensures the reliable functioning of the integrated RFID chips through continuous quality control. The chips can be individually programmed according to requirements. A combination with prefabricated functional labels is also possible. This opens up a wide range of possible applications: from removable documentation parts and integrated hanging brackets for infusion bottles to the integration of functional varnishes and safety features.

Schreiner MediPharm's customised service offers numerous advantages for the pharmaceutical industry. In addition to a high degree of customisation and fast delivery, process costs are reduced. As no minimum order quantities are required and warehousing costs are minimised, pharmaceutical companies benefit from a high degree of flexibility and cost efficiency. The Special design of the RFID labels with a special structure to protect the sensitive chip also guarantees RFID functionality from production to the end application.

Source: Schreiner MediPharm