Gerhard Schubert GmbH has comprehensively modernised its digital monitoring platform CARE („Connection for Analytics, Reporting and Efficiency“).

The aim of the further development is to enable users to analyse overall equipment effectiveness (OEE) even more precisely and flexibly. CARE has been an integral part of all new Schubert packaging machines since the beginning of 2025. Existing machines will be gradually adapted to the system.

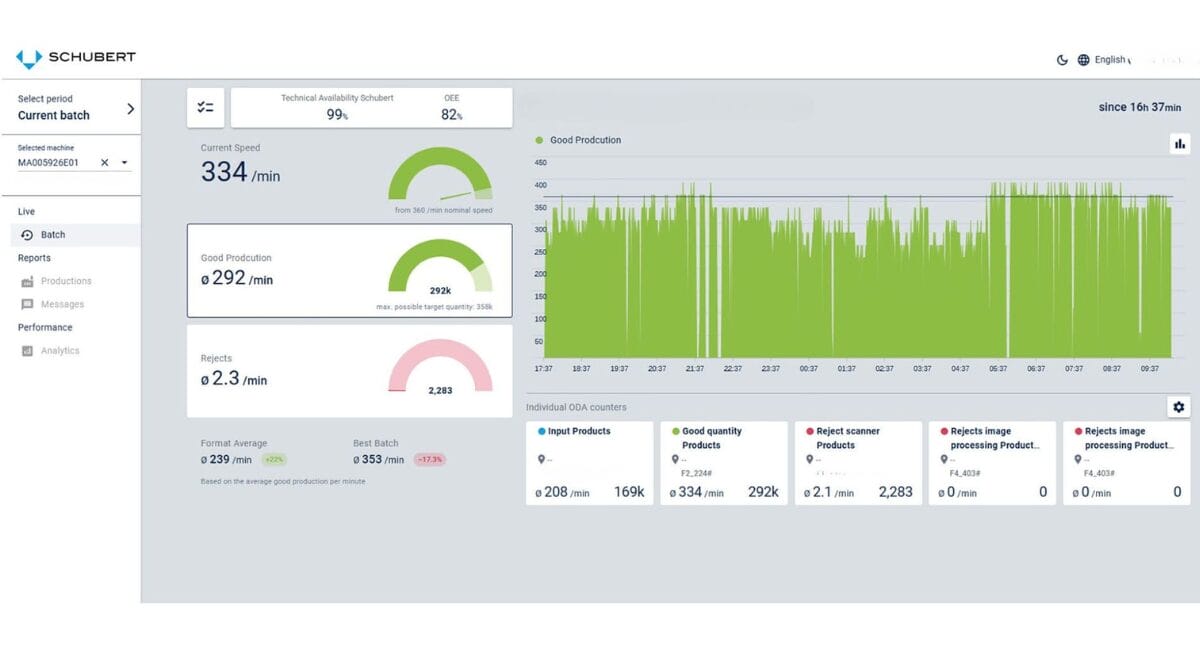

The CARE platform was first introduced in 2022 and has been a central element of the company's digital service portfolio ever since. Among other things, it records production speed, operating times, reject rates and throughput data. The information flows into a web-based dashboard via interfaces for machine control and quality assurance, which now offers additional functions and customisation options, according to the company.

OEE evaluation according to DIN EN 415-11

A central element of the updated platform is the standard-compliant calculation of OEE values in accordance with DIN EN 415-11, the European-wide standard that standardises key figures for the evaluation of packaging systems. Schubert now offers its customers a systematic and comparable basis for optimising their machine performance. For the first time, the infeed speed is also included in the calculation - a detail that further increases the informative value of the analysis.

„With the new OEE calculation, our customers can transfer optimisations across locations and increase the efficiency of their systems in a more targeted manner,“ explains Andreas Kepler, Lifecycle Product Manager at Schubert.

Data processing directly at the machine

Decentralised data processing is a major technical advance. Instead of the previous solution, in which the data was processed in Schubert's own IT environment, the machine itself will take over this task in future. According to the company, customers benefit from shorter access times and simpler data allocation, as the content displayed in the web portal matches the machine display.

„We want to provide our customers with fast, standardised and individually usable information - this requires new approaches to architecture.“

Sonja Burkert, Lifecycle Product Manager

Can be used online and offline

The platform can be used both online via a web portal and offline within the customer infrastructure - for example on the intranet or on stationary computers. This option is aimed at companies with increased requirements for IT security or individual visualisation. Schubert offers a licence model for this that ensures the usual presentation and functionality.

Source: Gerhard Schubert GmbH