Schütz is presenting a new ventilation system especially for IBCs in the Cleancert (CC) and Foodcert (FC) series. The company will also be presenting the Automatic Lock bung closure system, already established in the drum sector, for IBCs for the first time and the prototype of a new 3-skid steel pallet for transporting heavy loads.

Reliably protecting the quality of filled products throughout the entire supply chain is one of the core tasks of industrial packaging. This includes in addition to tamper-proofing, also minimises the risk of contamination such as particle ingress during use. Equipping components with sophisticated solutions plays a decisive role in optimising packaging standards.

New breather system for increased food safety

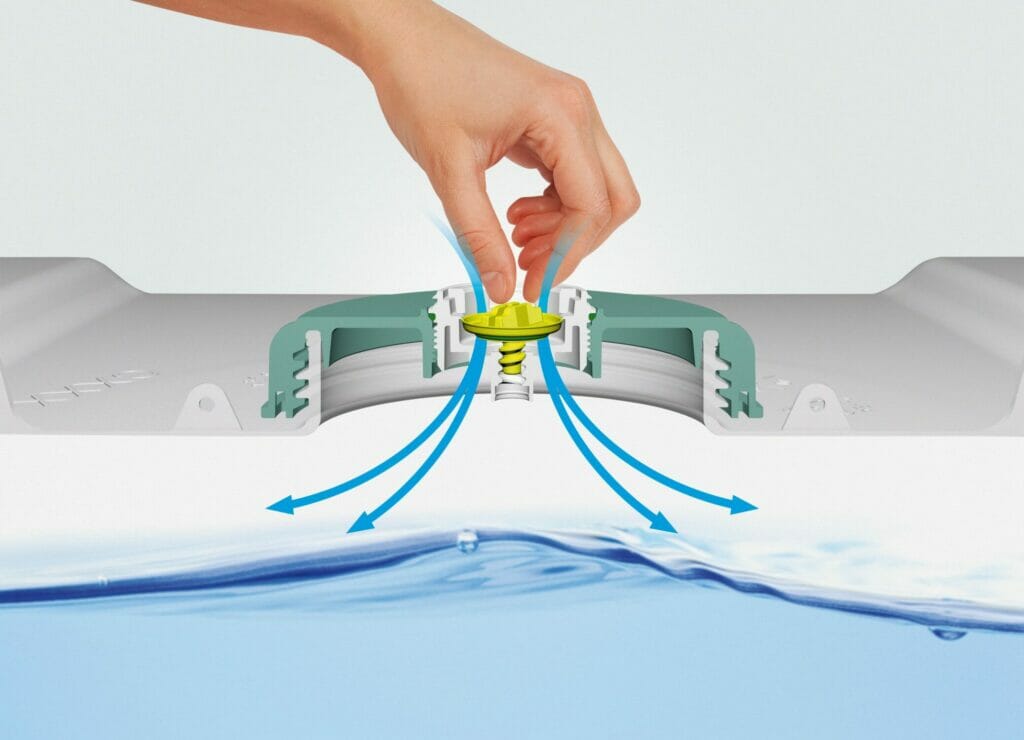

With the CC / FC Breather, Schütz is establishing another standard that has been specially developed for the Cleancert (CC) and Foodcert (FC) product lines. Especially at the beginning of the value chain, safety and risk minimisation have top priority in the food industry, for example. In the bung of the screw cap that covers the filling opening of the IBC, the new CC / FC ventilation system is integrated and enables the user to proactively avoid contamination risks. It serves to quickly and safely ventilate the container when emptying via the bottom outlet fitting and prevents negative pressure, which would lead to deformation of the inner container. With the previous systems, either the frequently sealed screw cap had to be opened or the bung plug had to be completely removed with tools.

The CC / FC Breather only requires the manual turning of a screw part with two fingers, so that only small ventilation paths are opened. This also minimises the risk of contamination during the entire emptying process. After emptying, the container can simply be closed and the emptied packaging is returned safely and in compliance with legal requirements. Schütz offers the system in two versions - with and without permanent ventilation - on. As an option, the packaging specialist can install a special membrane for transport, which also ensures ventilation and serves as splash and surge protection.

Maximum protection against tampering and contamination

Another example of the protection of filling goods is the firmly sealed Automatic Lock plastic bung closure system. Schütz is now also offering the solution already successfully used for PE drums for IBCs. In future, the company will supply all IBC customers who use a screw cap with stopper as standard.

The closure system with tamper-evident seal consists of a sealing cap and a stopper with special snap-in cams. The inner sealing ring is firmly attached to the stopper. The sealing cap is held in place by the stopper. After centring, a short press on the sealing cap places the locking ring behind the locking cams. The rigid design of the locking system offers the best possible hold when mounted. Due to the self-centring mechanism, the bung sealing system is suitable for manual and automatic installation. It is not possible to open the stopper without destroying the sealing cap. In this way, Schütz ensures that the originality of the filled medium is preserved.

The sealing cap can be removed easily, conveniently and without tools using the pull ring. In the event of improper loading, predetermined breaking points tear, making tampering immediately recognisable. Compared to metal caps, the plastic sealing cap of the Automatic Lock is non-corrosive. In particular for the filling of sensitive products, In the food and pharmaceutical industries, for example, the system with its advantages in the areas of hygiene and safety contributes significantly to the protection of the product and the employees.

New 3-skid steel pallet prototype

Schütz is presenting another innovation as a prototype: compared to the standard steel skid, the new 3-skid steel pallet has a new centre skid with a massively widened support surface. The solution developed by Schütz scores with a optimised weight distribution, robustness and greatly improved conveying properties. Thanks to its high stability and minimised deflection, even under load, the pallet is perfect for use in high-bay warehouses and with automated transport systems.

Source: Contactor

Schütz - More news

Schütz Nordic acquires majority stake in ScanDrums

Extra strong with third runner

Stability and sustainability with new canister series

Stirring viscous filling products safely in the IBC