Many tea boxes are wrapped in plastic film to protect the tea from moisture and oxygen. Lipton Manufacturing Poland has now switched to a Nordson hot melt dispensing solution to securely seal the cartons, thus eliminating the use of plastic film.

Lipton also packs tea boxes in plastic film to protect them from possible damage and tampering during transport. However, this packaging method has its disadvantages: plastic film is not biodegradable and therefore generates a lot of waste, which makes recycling more difficult. The company was therefore looking for a solution to reduce packaging waste and energy consumption. As a step towards sustainability, Lipton decided to minimise its ecological footprint and switch to a modern Hot melt dosing solution for secure sealing of cartons instead of using plastic film.

The new solution had to provide a barrier against moisture and other requirements, including fast and clean glue application without stringing, low adhesive consumption, high process reliability with reduced material degradation and an automatic adhesive filling system. The tea manufacturer then opted for a hot melt adhesive application system from Nordson. Lipton already works successfully with Nordson in other areas and values their extensive expertise in hot melt adhesive solutions.

„In 2021, we modernised the first production line on a trial basis. Our aim was to achieve 100 per cent efficiency by using adhesive instead of plastic film while ensuring high standards of cleanliness. This project is very much in line with our environmental values and aims to reduce plastic waste. As part of the project, we have modernised 14 production lines to cover 11 different sizes of tea cartons, from 20-bag to 100-bag versions.“

Robert Milej, Project Manager of Lipton Manufacturing Poland sp z.o.o.

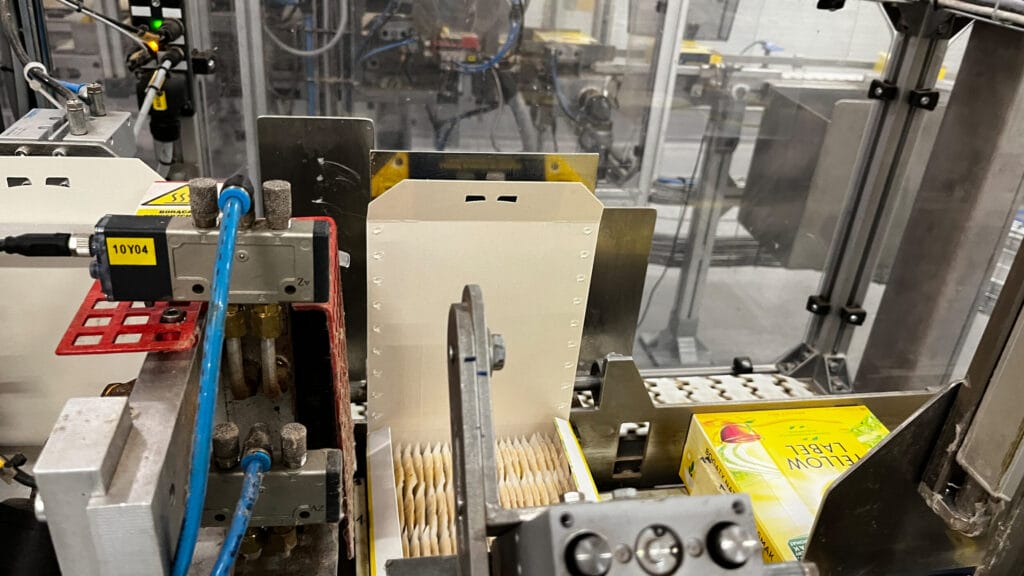

In total, Lipton two million tea cartons a day made. The company decided to modernise the existing production lines and installed Nordson Hot Melt systems for all 14 lines. The following are now used ProBlue Flex melters with melt-on-demand system, which is characterised by rapid heating of the adhesive at a constant temperature. It has an automatic filling system that prevents contact with the hot melt tank, ensuring a safe operating system.

The MiniBlue II SureBead application heads were integrated for precise adhesive application on the tea cartons. With automatic application pattern control, the system adjusts the amount and positioning of material to the size and shape of the cartons, ensuring ease of operation and minimising maintenance requirements. The MiniBlue II SureBead applicators are characterised by Lightweight, compact design for easy installation and maintenance out. Equipped with SureBead technology, these application modules prevent the nozzle from clogging and ensure consistent quality.

„Lipton's switch from plastic packaging to hot melt sealed cartons was a big step, where the reliability and speed of the MiniBlue II SureBead applicator played a major role. Ensuring precise sealing of the top flap of the carton with adhesive was critical.“

Grzegorz Lenarcik, Area Sales Manager at Nordson Packaging Poland

Nordson PureFlow hoses are specifically designed to reduce the risk of adhesive degradation and contamination and improve process reliability. The hoses have a special design and thus ensure Durability and reliability even at high temperatures and pressures. This property fulfilled Lipton's requirement to reduce adhesive degradation and the associated downtime.

By using Nordson systems, Lipton was able to fulfil all production requirements: There is now no more plastic waste, Efficiency and reliability in the packaging process have been increased and production losses reduced. Replacing plastic film with adhesive has increased production efficiency and brought about a positive, sustainable change.

„For the selected lines in this project, we have achieved 100% of our target and since the start of the project in 2020, we have been able to eliminate over 270 tonnes of film from our tea cartons every year,“ summarises Robert Milej. „In the near future, we want to Convert further packaging lines and glue instead of plastic film.“

SourceNordson