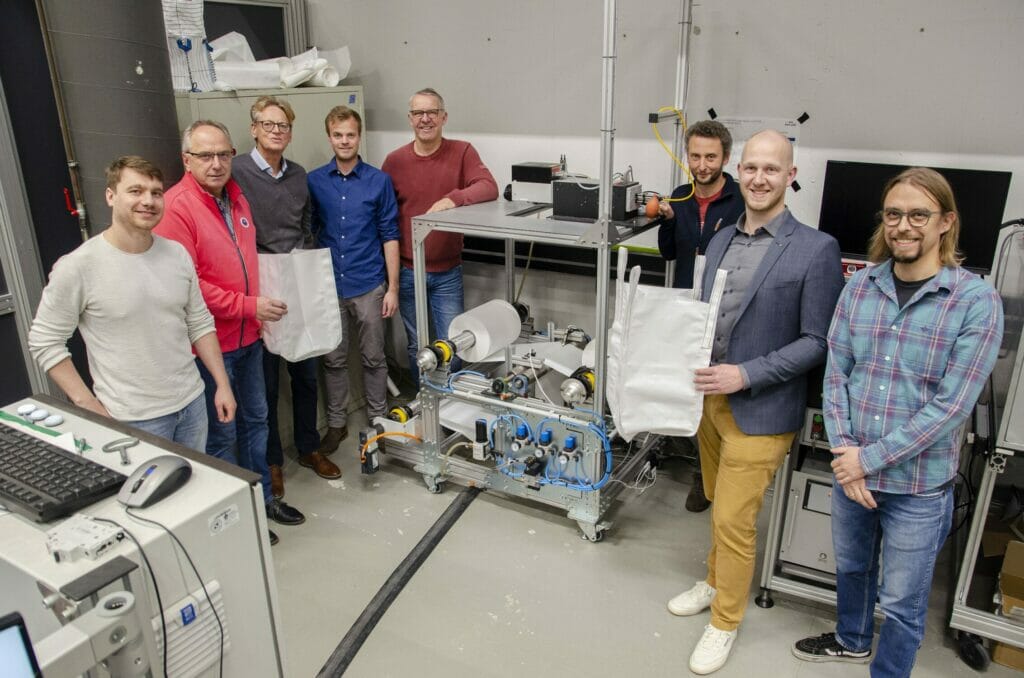

In a joint project, scientists from the Laser Centre at Münster University of Applied Sciences and the company Empac have found a method to seal big bags airtight. A new type of laser process and a specially developed automated machine system are used for this purpose.

In the chemical and pharmaceutical industries, highly sensitive raw materials are packed and stored in airtight packaging in so-called big bags. The high-quality packaging units prevent both dust and moisture ingress. The company Empac from Emsdetten, which manufactures the transport and storage containers - the big bags - has, however, recognised a problem in production: The packaging units are conventionally sewn together. However, each seam creates small holes, which in turn pose a potential risk of contamination.

The company has therefore turned to the Laser centre at the Department of Physical Engineering at Münster University of Applied Sciences to jointly search for an alternative that would allow the big bags to be sealed cleanly and with high strength. After two years of research, the team found a solution by using the Packaging material welded at the seams using an innovative laser process and a specially developed automated machine system. The ZIM project has now been completed for the time being. „ZIM“ stands for the „Central Innovation Programme for SMEs“ of the Federal Ministry for Economic Affairs and Energy. The programme supports companies in implementing their ideas with appropriate funding.

„We now have the opportunity to create reproducible seal-tight seams,“ explains Jan-Philipp Wessels, engineer and research associate at the Laser Centre. The team led by Prof Dr Evgeny Gurevich, graduate engineer Jürgen Gröninger and research assistants Alexander Steitz and Wessels have achieved this using the so-called „V-seam method“: A machine unwinds two rolls of the polypropylene or polyethylene fabric from which the big bags are made, and a laser welds them together in the centre under a defined contact pressure. „This allows us to heat the material with pinpoint accuracy and create a hermetically sealed and precise weld seam.“

Empac employee Norbert Bytomski also sees the advantage of the laser: „The laser creates a homogeneous joint and generates a constant temperature in the weld seam.“ It was important not to heat the material too much to prevent the fabric from shrinking. „This is called the memory effect,“ says Wessels. „It's similar to a rubber that is first stretched and then returns to its original shape. The aim was to avoid this.“ Accordingly, the team at the laser centre, which generally works with metals rather than plastics, carried out material tests to check how the fabric reacts to high temperature changes, for example.

„If we adjust the parameters accordingly, we can also process other plastics with the machine and the V-seam process,“ says Steitz. As part of the research project the Laser Centre has been able to prove that hermetically sealed welding is possible. Additional investigations and economic considerations are required for direct implementation in industrial production processes. The project partners agree that this requires further development work. „There are already interested companies that have expressed a strong interest in the innovative and contactless manufacturing process,“ says Wessels.

SourceFH Münster

IBC and Big Bags - More news

Redesign of IBCs for transporting sterile products

Merger for bag-in-box solutions

A successful symbiosis

New tool finds the most sustainable IBC for liquids