By 2030, all plastic packaging should be reusable or cost-effective to recycle. The EU Commission stipulates this in its key points in the „European Strategy for Plastics in a Circular Economy“. The packaging industry has a particular responsibility here. With the eTray meat tray® Sealpac presents a concept in which the functional material plastic is replaced to a large extent by fibres.

The Packaging industry is called upon to use materials even more responsibly and must present solutions that minimise the environmental impact of packaging, which is often indispensable. It is important to harmonise economy and ecology, because only solutions that are technically feasible and can also be implemented economically will be successful on the market.

A special focus here is on the Fresh produce segment, where there is currently no safe alternative to plastic packaging. The question arises as to how more sustainable solutions can be achieved using a lower proportion of plastic that still fulfil the necessary requirements. Moisture or oxygen barriers offer.

Paving the way for sustainable plastic packaging

Many companies in the packaging industry have been working on this topic for years and have already achieved notable successes, including the Sealpac GmbH from Oldenburg.

The provider of high-techTraysealers and -Thermoformers and developer of innovative packaging concepts, in co-operation with leading tray and film suppliers in the industry, succeeded years ago in reducing the weight and thus the use of materials for one of the most popular tray formats in the meat segment in Europe, the Meat tray 190 x 144 x 50 millimetres.

While this shell still weighed 18 grams in 2003, its weight was reduced while at the same time significantly improving the Machinability and the processing convenience of the trays to less than ten grams.

eTray®: „e“ like „ecological“

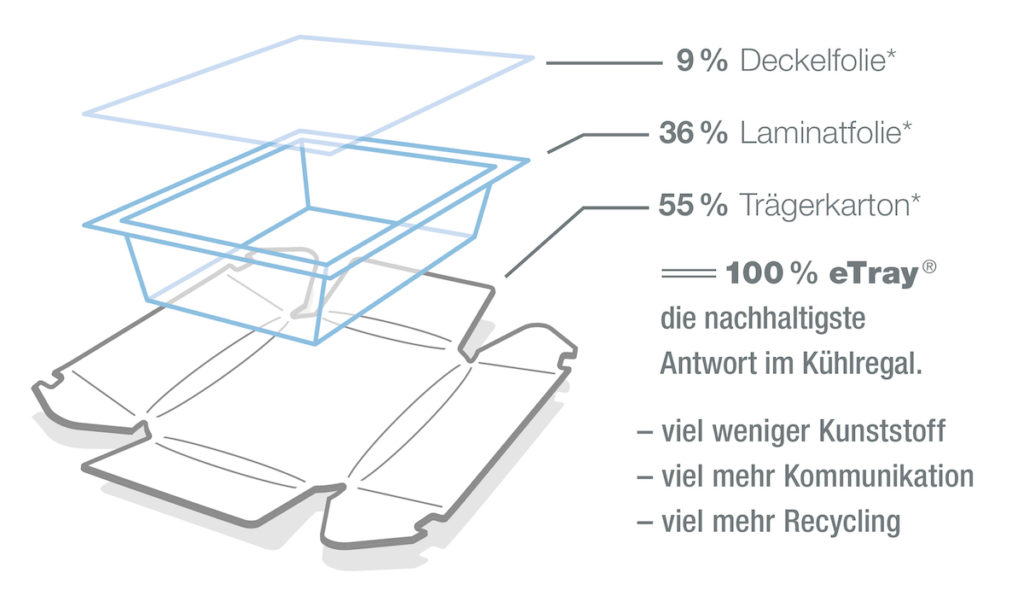

The Sealpac development, which is based on the IFFA 2019 The innovative shell, which celebrated its première, is suitable for a wide range of applications. MAP applications for high-quality meat and other fresh products, for example. It consists of around 55 per cent Cardboard box, about 36 per cent from a Plastic inlay in mono quality and around nine per cent from the top film.

It is a double-sided, high-quality printable Cardboard die-cut with a plastic inlay as a sealing and functional medium. eTray® is supplied as a prefabricated tray, is dimensionally stable, can be unstacked and is characterised by excellent machinability.

Compared to conventional comparable Packaging trays This saves 40 to 60 per cent plastic. In addition, eTray requires® significantly less high-quality carrier or fibre material than comparable systems with an ecological approach.

After use, the backing material and plastic inlay can be easily separated by the consumer and disposed of separately.

At the PoS, the packaging stands out due to its extraordinary look and plenty of space for information such as the sustainability of the packaging or handling during disposal.

Already established: FlatSkin®

The eTray thus follows®-concept follows the basic motto „Less plastic, more communication!“, according to which Sealpac already very successfully introduced the packaging concept two years ago. FlatSkin® has established itself on the market, a plastic-cardboard solution for skin applications.

With FlatSkin® - i.e. the skinning of a product onto a surface coated with a wafer-thin Barrier plastic layer laminated cardboard carrier - the focus is on reducing packaging material and improving recycling, also combined with eye-catching packaging with plenty of space for communication.

Sustainability that pays off

The question naturally arises as to the cost of packaging such as eTray® or FlatSkin® and acceptance by consumers. Currently, the more sustainable packaging cannot be produced in a cost-neutral way compared to conventional products.

The production of packaging such as eTray® is, despite or perhaps because of the clear Plastic reduction, The process is more complex and is realised in several production steps.

However, thanks to their unusual appearance, they offer the opportunity to position themselves in an eye-catching way and emphasise the high quality of the product and the manufacturer's sustainability efforts.

And that strikes a chord with consumers. For them, the sustainability of the packaging is definitely a Purchase argument, This was confirmed by a 2018 study commissioned by Pro Carton, which found that 77 per cent of respondents are willing to pay more for sustainable packaging. However, the majority of them (90 per cent) also demand more information about the Environmental friendliness the packaging.

This is precisely where the Sealpac developments eTray® and FlatSkin® with plenty of high-quality printable cardboard surface.

[infotext icon]You can find more information about the Sealpac range on the company website:

http://www.sealpac.de

Sealpac at FachPack 2019: Hall 3, Stand 441