For the second time, companies from Packaging Valley are focussing on the exchange between young talents, start-ups and experienced specialists for future projects. The 2nd Packaging Valley Makeathon will take place from 9 to 10 November.

Eight locations, eight project partners and eight different topics promise two exciting days. These include companies from the packaging machinery industry and research institutes. The topics range from from sustainability issues to innovative solutions for digital and efficient processes. The two days bring a lot to the companies, but also to the participants: interesting insights into company processes, new perspectives, new contacts, a foot in the door and helping to shape the future.

The format Makeathon has the Packaging Valley has already been successfully organised with partners from the region. This year, the event will once again be supported by ITQ GmbH as co-organiser, which is committed to promoting the future topics of digitalisation and sustainability. Invited are students, young professionals or people with professional experience - tech-savvy brains with a „tinkerer and doer gene“. They don't have to come from the packaging industry. What they should bring with them is an interest in sustainable business processes and innovative and digital solutions. Over the course of two days, participants will be tinkering, exchanging ideas, programming, tinkering and pitching.

„The first event of this kind last year already showed that more can come of it. Patents were registered and new talent was recruited. So we are excited to see what results come out this year, which projects will be pursued further or who will even come on board at the companies.“ Martin Buchwitz, Managing Director of the packaging network

Topics of the Valley Makeathon

How can the Machine operation of the future ask themselves the Packaging machine manufacturer Harro Höfliger from Allmersbach im Tal. The world of work is changing. Machines are becoming increasingly automated. This makes the question of how to ensure safe and efficient operation all the more important. At the Waldbrunn site, everything revolves around the Green digital Twin. Specifically, it is about minimising the CO2 footprint with the help of digital solutions. The strapping company Mosca was recently honoured as the most sustainable machine and system manufacturer. Syntegon, formerly Bosch Packaging Technology, from Waiblingen is working on the Digital/mechatronic machine logbook. Digital and automated solutions are required here, as well as possible extensions through sensor solutions.

The Schwäbisch Hall-based packaging company Optima is focussing on what sustainable procurement can look like in the long term. For two days, the company will be working on specific future models for the Sustainable procurement topics „Green logistics, environmental management with a focus on waste & hazardous substances and supply chain law“.

At the Virtual Dimension Centre in Fellbach, the theme is Mixed reality for hybrid prototyping in packaging machine construction. Participants develop a mixed-reality model of a packaging machine consisting of digital (in virtual reality) and physical elements that can be tested and optimised visually and haptically at the very early stages of machine development. With the digital recording of labels and assessment of packaging is the focus of the Zebra Engineering project at the Heilbronn site. They are using the two days effectively to reduce the hardware variance frequently used by customers. More efficient processes are the goal.

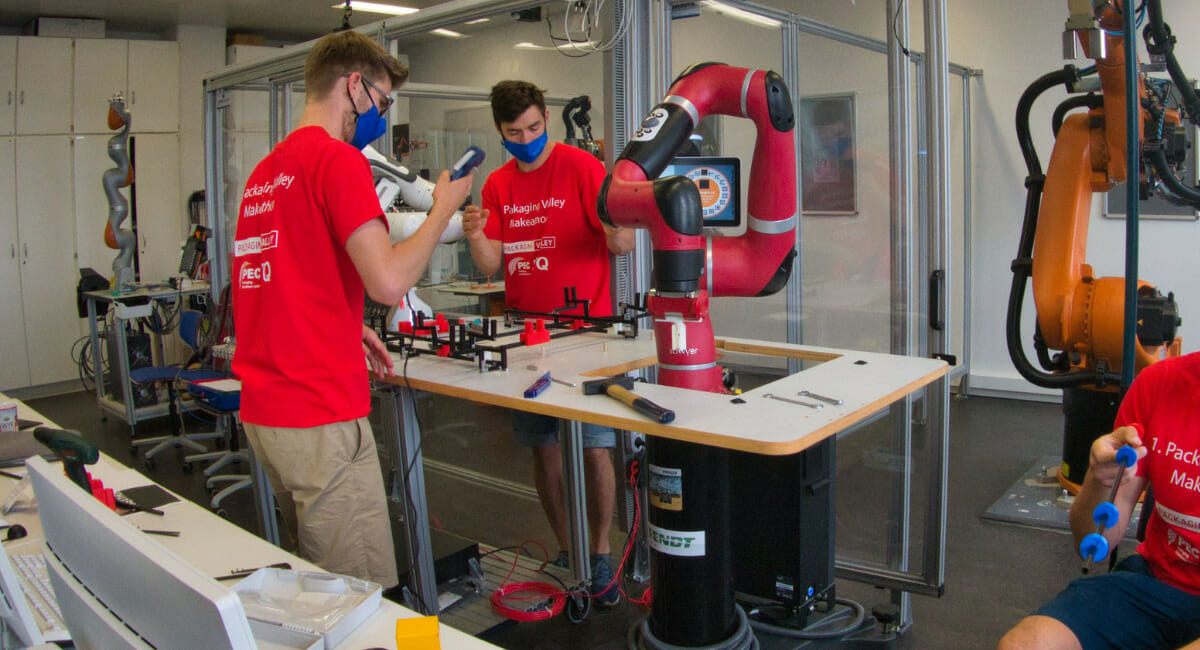

At Kempten University of Applied Sciences, students in the Kuka Laboratory - Digital Factory and the Wittenstein Laboratory for Mechatronics on tasks set by companies from Packaging Valley. The students can utilise the technologies available in the labs, such as industrial robots, robots for human-robot collaboration, AI-based image processing systems and 3D printers. During the two days, the aim will therefore be to develop an automated solution using robots for specific tasks in packaging technology and to realise a demonstrator in the laboratory.

The „Digitalisation, Education and Qualification Foundation (DBQ)“ and the start-up Kimoknow provide support at the KIT-IMI site in Karlsruhe in the implementation of AI applications from the cloud. The efficient flow of information according to the concepts of digitalisation and Industry 4.0 is crucial for the connection of AI applications in industrial environments. AI cloud applications are prototypically implemented in a shop floor environment with a wide range of hardware and software components.

Source: Packaging Valley